Definition and Core Function of an Ultrasonic Transducer

What Is an Ultrasonic Transducer?

Ultrasonic transducers work as electroacoustic devices converting electrical signals into those high frequency sound waves we can't hear, typically above 20 kHz. They also do the reverse process when needed, which makes them fundamental parts of any ultrasound system. These little gadgets send out and pick up acoustic energy without actually touching anything, allowing for measurements that don't damage materials. We can measure distances, spot flaws inside materials, even look at what's going on within objects just by timing how long it takes for echoes to come back. Since they operate outside our hearing range, there's hardly any interference from other sounds around them. That's why doctors rely on them so much for imaging inside bodies, factories use them all over the place for quality checks, and automation systems depend on their precision because getting accurate readings matters a lot for safety reasons too.

Energy Conversion Mechanism in Ultrasonic Transducers

Ultrasonic transducers work because of something called the piezoelectric effect. Apply an electric field to materials like lead zirconate titanate (or PZT for short) and these materials actually change shape physically while producing ultrasonic waves. The process works both ways too. When sound waves hit the material, they create pressure that turns back into electricity through what's known as the inverse piezoelectric effect. What makes this whole system so useful is how fast it converts between electrical signals and mechanical movement. This quick back-and-forth allows devices to send out and pick up signals almost instantly, which is really important if we want good accuracy in sensing applications or medical imaging.

Key Components and Piezoelectric Technology

Modern ultrasonic transducers consist of three functional layers that optimize performance:

- Piezoelectric element: PZT crystals generate vibrations when energized, forming the core transduction mechanism

- Backing material: Absorbs rearward waves to reduce ringing and improve pulse definition, enhancing bandwidth

- Acoustic matching layer: A quarter-wavelength impedance-matching barrier that maximizes energy transfer into the medium

Recent advancements in polymer-ceramic composites have improved durability and frequency response (Materials Science, 2023), expanding use cases from micro-electromechanical systems (MEMS) to high-power cleaning and medical diagnostics.

Working Principle of Ultrasonic Transducers: Signal Generation and Reception

Ultrasonic transducers work by turning electrical energy into mechanical vibrations and then changing those vibrations back into electricity. Most of them rely on special materials called piezoelectrics, such as PZT ceramics, which do all this magic. These devices send out sound waves way beyond what humans can hear, usually somewhere between 20 kilohertz and 20 megahertz. Those waves go bouncing through different stuff - air, water, even metal objects. When they hit something new or find a crack in whatever material they're passing through, they bounce back like an echo. What happens next is pretty cool: the same transducer that sent out the wave catches the returning signal and turns it back into electrical information. By measuring how long it takes for the wave to come back, engineers can figure out exactly how far away something is or how deep a particular feature might be within a material.

When talking about performance, we really need to look at those core numbers that matter most. Bandwidth tells us what frequency range something can pick up on, while sensitivity basically shows how well it separates useful signals from background noise. Take industrial flaw detection for example. The industry standard these days demands transducers with around plus or minus 2 dB sensitivity just to spot those tiny cracks smaller than a millimeter in metal parts. Pretty impressive stuff actually. These modern systems now hit over 90% accuracy even when signals travel up to 15 meters away. That kind of reliability opens doors across many fields including robotics where precision matters, medical imaging where clarity saves lives, and keeping track of building structures to make sure they stay safe over time.

Types of Ultrasonic Transducers and Structural Design Variations

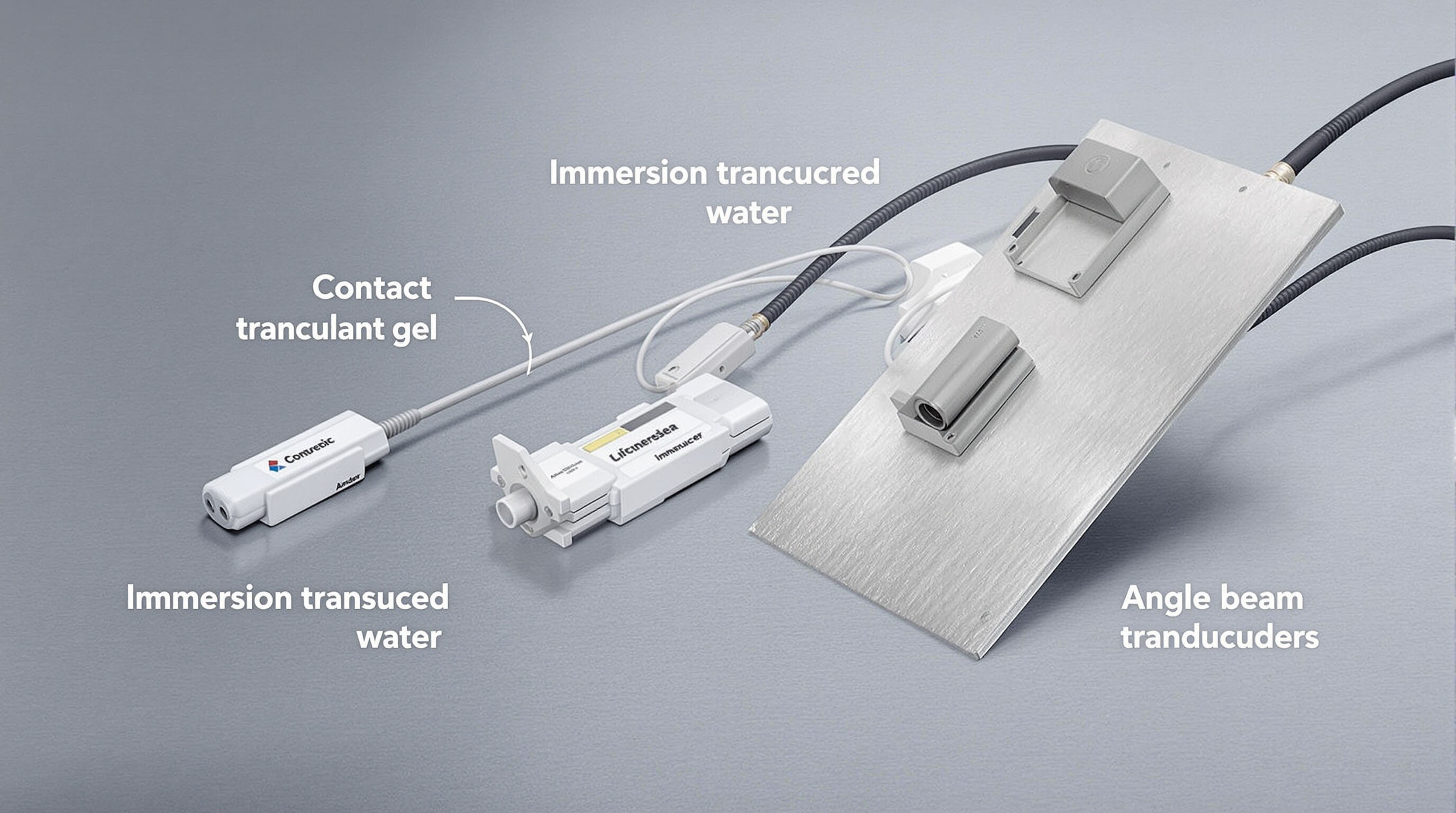

Contact, Immersion, and Angle Beam Transducers

The way transducers are designed really depends on what kind of inspection environment they'll be used in. For contact transducers, technicians apply them directly onto surfaces with things like gels or greases as couplants. This helps get better energy transfer when checking welds on pipelines or looking at structural steel components. Then there are immersion transducers which work best underwater or in other liquid environments. They give much better sensitivity readings and create more consistent coupling conditions, so they're great for detailed tests on aerospace materials and small precision parts where accuracy matters most. Angle beam transducers shoot sound waves at around 45 to 70 degrees off the surface, helping find those tricky flaws that run perpendicular to the surface itself. These particular types have become essential tools for maintenance crews working on turbine blades, rail systems, and all sorts of layered joint structures across various industries.

High-Frequency Transducers (20–80 MHz) and Their Use Cases

High-frequency transducers deliver exceptional resolution for fine-detail imaging. Their applications are frequency-dependent:

- 20–30 MHz: Used for bondline inspections in microelectronics and lithium-ion battery layers

- 50–80 MHz: Enable subsurface imaging of skin lesions and corneal thickness mapping in ophthalmology

These transducers incorporate advanced damping materials to minimize signal ring-down, achieving axial resolutions below 50 μm—critical for early melanoma detection and non-invasive eye diagnostics.

Medical Applications of Ultrasonic Transducers in Diagnostic Imaging

Ultrasound Imaging in Medicine: Role of Ultrasonic Transducers

Medical ultrasound wouldn't work without ultrasonic transducers, those devices that create sound waves ranging from about 2 to 18 MHz so doctors can see inside the body as it happens. When using B-mode imaging, these transducers send out quick bursts of sound and then listen for what comes back, building detailed pictures of organs, how blood moves around, even baby development during pregnancy. What makes them so useful is their capability to tell apart different types of soft tissues, which helps doctors spot heart problems, find tumors early on, and monitor potential issues during pregnancy. Most clinics actually rely on piezoelectric ceramic transducers because they offer good accuracy and aren't harmful to patients. According to research published in the SPIE Journal of Biomedical Optics back in 2014, this type accounts for more than 85% of all ultrasound equipment used in hospitals today.

High-Frequency Transducers in Dermatology and Ophthalmology

High frequency transducers in the 20 to 80 MHz range give doctors an amazing level of detail when looking at skin problems, helping tell apart harmless spots from potentially cancerous growths. Eye specialists have also found these tools useful for checking the front part of the eye without much hassle, they can measure how thick the cornea is and spot issues such as keratoconus pretty easily. Some research published last year showed that pairing these high freq ultrasound devices with artificial intelligence actually boosted melanoma detection rates by about 37 percent, which makes a real difference in early diagnosis.

Advancements in Real-Time Imaging and Signal Processing

New developments now allow for frame rates over 1,000 Hz, which means we can actually see fast moving things inside the body like heart valves opening and closing. The tech behind this includes these fancy dual layer piezoelectric components plus some smart software called adaptive beamforming algorithms. This combination works wonders for getting clear images even when imaging obese patients who typically give doctors headaches. According to research published in Ultrasound in Medicine & Biology last year, these improvements boost Doppler sensitivity by nearly 30%. Clinically speaking, this translates to spotting tiny calcium deposits in breasts much sooner than before and guiding surgeons with pinpoint accuracy during operations that require only small incisions.

Industrial Applications of Ultrasonic Transducers in Non-Destructive Testing

Ultrasonic Non-Destructive Testing (NDT) Principles

Ultrasonic transducers play a key role in non-destructive testing (NDT). These devices work with frequencies ranging from about 0.1 to 50 MHz to find problems inside materials without causing any damage. Looking at market trends, the oil and gas sector makes up around 33% of all NDT equipment purchases worldwide according to Future Market Insights data from 2025. This high demand comes mainly from companies needing to check pipelines for integrity issues and monitor corrosion over time. When these transducers analyze how long echoes take and their strength, they're able to spot various defects including cracks, empty spaces, and even thin spots in metal walls measuring just 0.1 millimeters thick. Such capabilities help maintain safety standards and meet regulatory requirements across industrial applications.

Distance Measurement and Ranging Systems Using Ultrasound

Ultrasonic transducers work really well in industrial environments where traditional methods struggle. These devices can accurately measure liquid levels inside tanks to within about 1 percent, and they keep working properly even when there's fog, dust floating around, or vapor present. That's why many facilities in chemical processing plants and mines prefer them over optical sensors that get confused by these conditions. Another thing that makes ultrasonic tech stand out is how tough it is. This durability means these transducers are commonly used not just for basic measurements but also in more complex applications like helping robots navigate safely, preventing collisions between equipment, and keeping track of stock levels in those massive automated warehouses we see popping up everywhere these days.

Case Study: Flaw Detection in Aerospace Components

Aerospace manufacturers employ ultrasonic transducers to detect fatigue cracks smaller than 50 μm in turbine blades, improving safety compliance by 42% compared to traditional X-ray methods (Nature 2023). Using high-frequency (15–25 MHz) phased array technology, these systems map internal defects in jet engines and airframe welds with high spatial resolution.

| Application | Frequency Range | Defect Detection Threshold |

|---|---|---|

| Pipeline Inspection | 1–5 MHz | 0.5 mm cracks |

| Turbine Blade Scan | 15–25 MHz | 20 μm micro-fissures |

| Composite Material | 5–10 MHz | Delamination >2 mm² |

This combination of precision, scalability, and non-destructive operation makes ultrasonic testing a cornerstone of quality assurance in high-risk industries like aviation and energy.

FAQ

What is the main use of ultrasonic transducers?

Ultrasonic transducers are mainly used for measuring distances, detecting flaws within materials, and diagnostic imaging in medical applications.

How do ultrasonic transducers work?

Ultrasonic transducers convert electrical signals into high frequency sound waves and can change vibrations back into electricity using the piezoelectric effect.

What are some common types of ultrasonic transducers?

Some common types include contact transducers, immersion transducers, and angle beam transducers, each suited for different inspection environments.

Are ultrasonic transducers used in medical imaging?

Yes, ultrasonic transducers are crucial for ultrasound imaging in medicine, particularly for observing and diagnosing issues in soft tissues and organs.

Table of Contents

- Definition and Core Function of an Ultrasonic Transducer

- Working Principle of Ultrasonic Transducers: Signal Generation and Reception

- Types of Ultrasonic Transducers and Structural Design Variations

- Medical Applications of Ultrasonic Transducers in Diagnostic Imaging

- Industrial Applications of Ultrasonic Transducers in Non-Destructive Testing