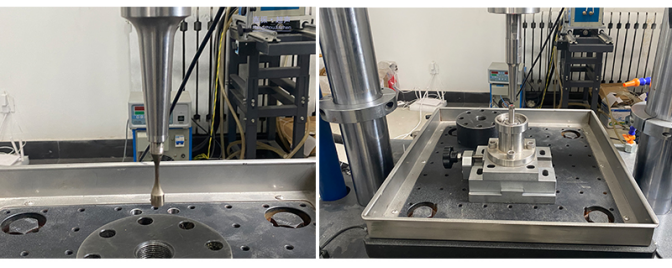

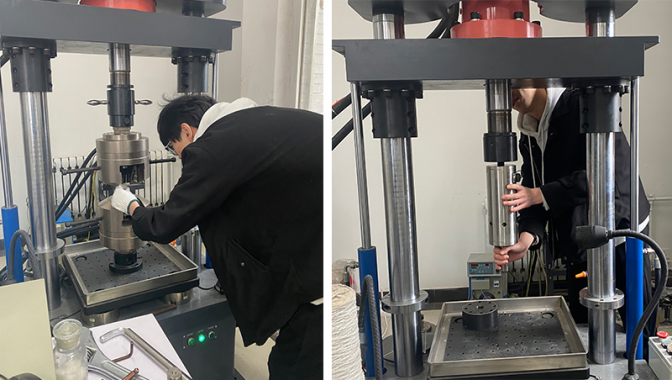

On March 18, 2023, the high-temperature ultra-high cycle fatigue test system customized for Northwestern Polytechnical University by Hangzhou Jiazhen Ultrasonic Technology Co., Ltd. was successfully accepted in the Northwestern Polytechnical University laboratory.

Our technicians assembled the equipment and debugged it. They demonstrated and completed various materials fatigue and fracture tests for relevant personnel in the laboratory. They explained in detail the composition, principles and usage methods of the equipment, and answered the questions raised by teachers and classmates one by one. The two sides conducted a series of technical exchanges and discussions.

The ultrasonic fatigue test system is used to conduct tests for measuring the fatigue characteristics, fatigue life, prefabricated cracks and crack propagation of alternating loads of metals, alloy materials and their components at room temperature. In view of the ultra-long life and ultra-high reliability requirements of modern mechanical equipment parts, traditional fatigue testing technology can no longer meet the current requirements. Ultrasonic fatigue test is an accelerated resonance fatigue test method, which can greatly shorten the test time and is the only available solution for ultra-longevity fatigue test of aircraft engine blades. The HCSONIC multi-function ultrasonic fatigue test system designed and produced by our company is subject to research and customization by various research institutions and universities, and undertakes the ultra-high cycle fatigue test business.