Introduction

Ultrasonic mechanical effect refers to the general term for various mechanical effects produced by the interaction between ultrasonic waves and the medium when they propagate in the medium. Specifically, when ultrasonic waves propagate in the medium, they will cause the vibration of particles in the medium, and this vibration will produce mechanical effects, such as displacement, deformation, acceleration, etc.

The ultrasonic energy acting on the medium will cause the particles to vibrate slightly at high speed, resulting in changes in mechanical quantities such as velocity, acceleration, sound pressure and sound intensity, thereby causing mechanical effects. Ultrasonic waves are a form of mechanical energy propagation, which is related to the wave process and will produce linear vibration effects. When ultrasonic waves propagate in the medium, although the amplitude of particle displacement is very small, the particle acceleration caused by ultrasound is very large.

If 20kHz, 1W/cm² ultrasonic waves propagate in water, the sound pressure amplitude generated is 173kPa, which means that the sound pressure amplitude must change between positive and negative 173kPa 20,000 times per second, and the maximum particle acceleration reaches 1440km/s², which is about 1500 times the acceleration of gravity. Such intense and rapidly changing mechanical motion is the mechanical vibration effect of power ultrasound.

When the ultrasonic medium is not a uniform layered medium (such as biological tissue, human body, etc.), the different acoustic impedances of each layer of the medium will cause the propagating sound wave to reflect and form a standing wave. The antinodes and nodes of the standing wave cause changes in pressure, tension and acceleration. Due to the different masses of different medium particles (such as biological molecules), the vibration speed caused by the pressure change is different, and the pressure change caused by the relative movement between the medium particles is another reason for the ultrasonic mechanical effect. The mechanical effect of ultrasound is used for processing (punching, cutting, compacting, surface strengthening, welding, cleaning, polishing and removing unwanted films and dirt, etc.), and is also used to accelerate other processes such as dispersion, homogenization, emulsification, crushing, sterilization, etc.

Based on principle

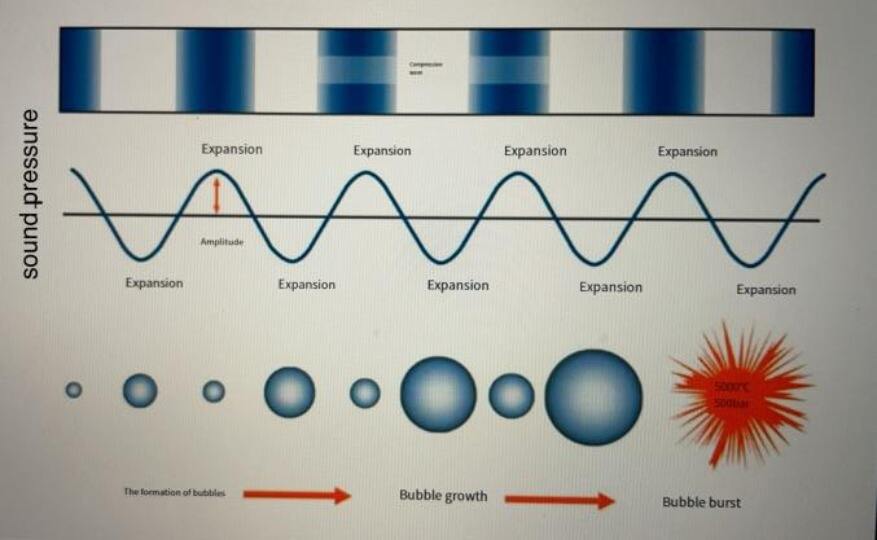

The principle of ultrasonic mechanical effect is mainly based on the cavitation effect, mechanical vibration effect and thermal effect generated when ultrasonic waves propagate in the medium. The cavitation effect means that in the liquid, the negative pressure area generated by ultrasonic waves will cause the gas or steam in the liquid to form small bubbles. These bubbles will expand and collapse rapidly under the action of ultrasonic waves, generating strong impact force. The mechanical vibration effect means that when ultrasonic waves propagate in the medium, the particles in the medium will vibrate. This vibration will generate shear force and extrusion force, thereby changing the physical properties of the medium. The thermal effect means that when ultrasonic waves propagate in the medium, due to the vibration and friction of the particles in the medium, heat will be generated, causing the temperature of the medium to rise.

Application Areas

1. Mechanical stirring

The high-frequency vibration and radiation pressure of ultrasound can form effective stirring and flow in gas and liquid. The strong jet and local micro-flow generated by the vibration of cavitation bubbles on the solid surface can significantly reduce the surface tension and friction of the liquid, and destroy the boundary layer of the solid-liquid interface, thus achieving the effect that ordinary low-frequency mechanical stirring cannot achieve. This effect is the physical basis for the application of drug penetration, cosmetic introduction into the skin, ultrasonic degassing, food and cosmetics blending and refining.

2. Mutual diffusion

Using the pressure and high temperature effects of ultrasonic vibration and cavitation, the mutual penetration of molecules between two liquids, two solids, or liquid-solid or liquid-gas interfaces is promoted to form new material properties. Ultrasonic welding of metals or plastics, ultrasonic emulsification, cleaning, and atomization can be classified as such effects.

3. Homogenization

The local shock wave generated after the cavitation bubble closes can crush the particles in the liquid and make them fine; make the crystals uniform; disperse the larger and uneven emulsion droplets into tiny uniform medicines (such as medical contrast agents, anti-cancer drugs, etc.); and even include the effects of dissolving blood clots.

4. Coagulation

Ultrasonic vibration can make the suspended particles in the gas and liquid media move at different speeds, increasing the chance of collision; or use standing waves to make them tend to the antinode, so that the coagulation process occurs. Flue dust collection and artificial rainfall can belong to this category.

5. Mechanical cutting

Due to the large acceleration of ultrasonic vibration and the acoustic corrosion of cavitation, hard and brittle materials (gems, ceramics, glass, magnetic steel, etc.) can be processed with special precision.

6. Crushing

Using high-intensity ultrasonic pulses, kidney stones and gallstones in the human body can be crushed without damaging soft tissues.

Conclusion

Ultrasonic mechanical effects are widely used in medicine, industry, agriculture and other fields. In the medical field, ultrasonic mechanical effects can be used to diagnose and treat diseases, such as ultrasonic lithotripsy, ultrasonic wound cleaning, etc. In the industrial field, ultrasonic mechanical effects can be used in cleaning, welding, cutting and other processes. In the agricultural field, ultrasonic mechanical effects can be used to promote plant growth and increase crop yields.

In addition, the mechanical action of ultrasound can also soften tissues, enhance penetration, improve metabolism, promote blood circulation, stimulate the nervous system and cell function, etc., so it has unique therapeutic significance. For example, in medical ultrasound therapy, the mechanical effect of ultrasound can promote the penetration and diffusion of drugs and improve the efficacy of drugs; at the same time, it can also stimulate the permeability of cell membranes and promote cell metabolism and regeneration.

In short, ultrasonic mechanical effect is the general term for the mechanical effect produced when ultrasound propagates in a medium. It has a wide range of applications and unique therapeutic significance in many fields.