An ultrasonic transducer is an energy conversion device that converts input electrical power into mechanical power (i.e., ultrasound) for transmission, while it itself consumes only a minimal amount of power.

The ultrasonic generator (also known as an ultrasonic power supply) converts 220V AC into high-frequency current, which is transmitted to the piezoelectric ceramic. The piezoelectric ceramic, resonating at ultrasonic frequencies, uses the piezoelectric effect to convert electrical signals into linear mechanical vibrations. These vibrations are then amplified (or attenuated) in amplitude via an ultrasonic horn before being delivered to the tool head for operation. Ultrasonic transducers generally come in two forms: magnetostrictive and piezoelectric ceramic. Our company exclusively uses piezoelectric ceramic transducers.

Magnetostriction: The effect where materials deform under the influence of a magnetic field or generate a magnetic field when deformed. These materials typically contain nickel, which exhibits strong magnetostriction. Magnetostrictive sensors utilize magnetostrictive materials (usually in laminated form). Due to eddy currents, magnetostrictive transducers generally have higher losses compared to piezoelectric transducers, necessitating more stringent cooling requirements.

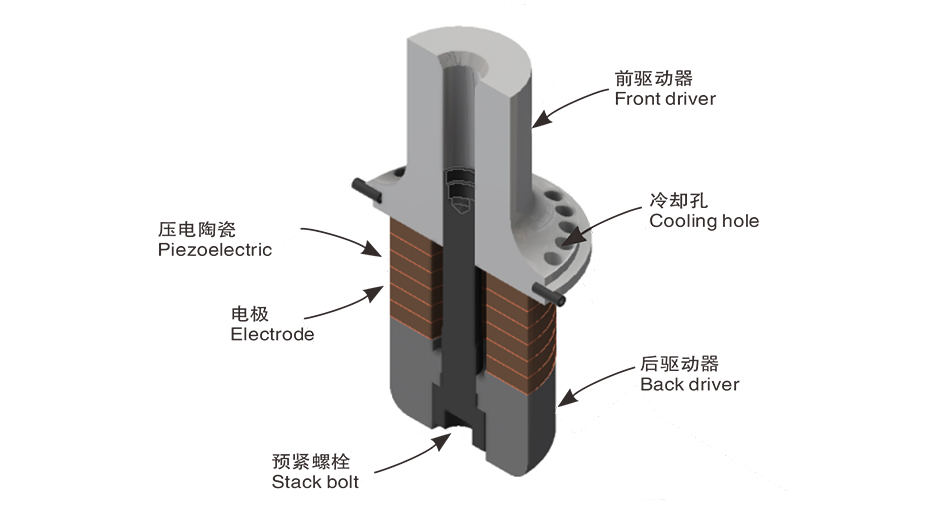

The composition of ultrasonic transducers

Almost all piezoelectric transducers used for power ultrasound are of the Langevin type, that is, one or more piezoceramics are mechanically compressed (pre-stressed) between a front driver and a rear driver.

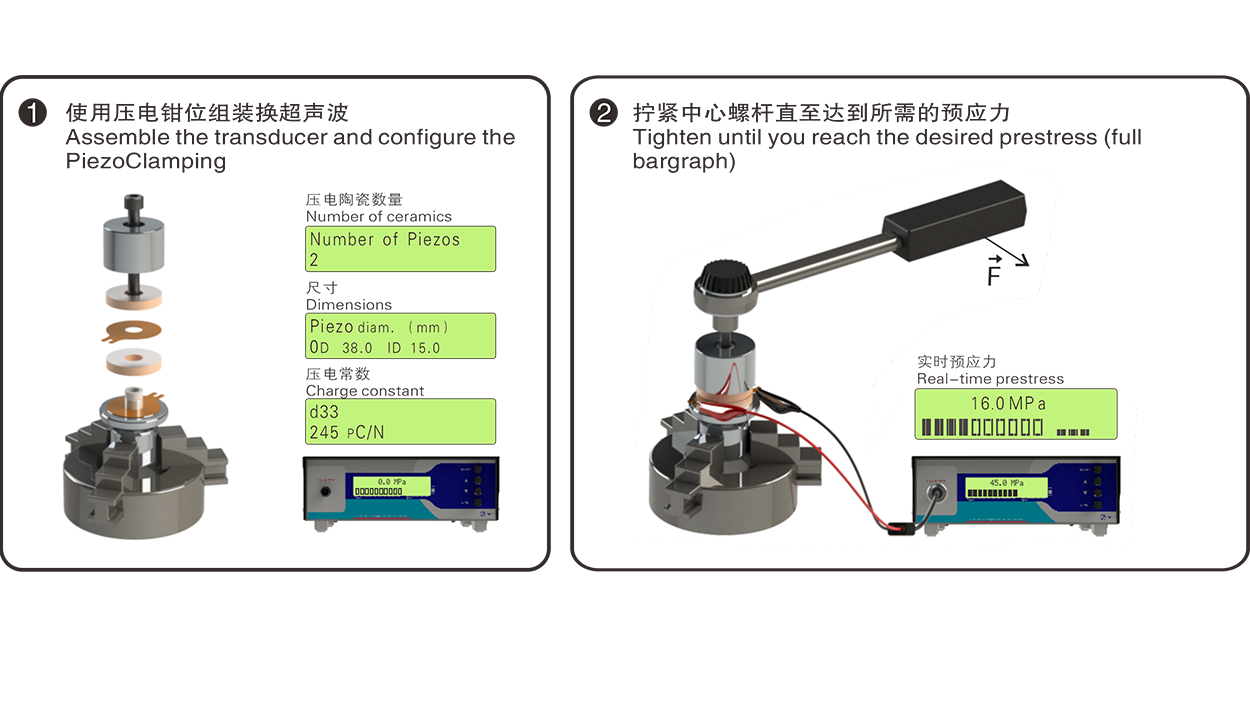

Ultrasonic transducers consist mainly of central piezoceramic elements, front and rear metal covers, prestressed bolts, electrode sheets, and insulating tubes, as detailed in the diagram below. Nearly all piezoelectric transducers used for power ultrasound are of the Langevin type, which involves one or more piezoceramic elements being mechanically compressed (pre-stressed) between a front driver and a rear driver.

Rear driver: A cylindrical element located on the backside of the piezoelectric transducer. The rear driver is adjacent to the last piece of piezoelectric ceramic and typically applies preload pressure through stacked bolts.

Electrode plate: A thin conductive disk placed between adjacent piezoelectric ceramics in a transducer. The transducer drive voltage is applied across these electrodes.

Front driver: Transmits the ultrasonic energy of the transducer to the horn or tool head, and the front driver typically includes an installation flange for connecting to the housing.

Pre-stressed bolt: A single stack bolt passes through the central hole of the ceramic. After tightening this bolt, the ceramic will be compressed between the rear driver and the front driver, thereby applying the required pre-stress to the ceramic.

Piezoelectric ceramics: Piezoelectric ceramics are the heart of transducers, converting the electrical signals from ultrasonic generators into linear mechanical vibrations.

piezoelectric ceramic disc

transducer core components

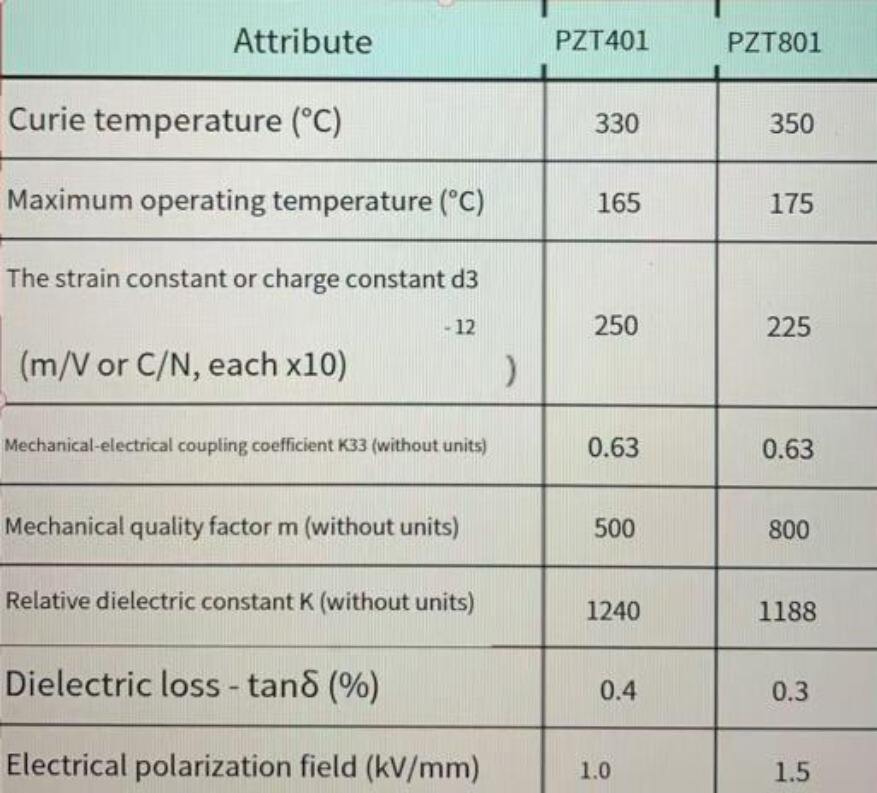

Piezoceramics are generally divided into 'soft' or 'hard'. Hard piezoceramics are used for electrical applications. There are two basic types of hard piezoceramics, commonly referred to as PZT-4 and PZT-8 (PZT stands for lead zirconate titanate, the composition of piezoceramics). All our transducers use PZT-8 piezoceramics. PZT-8 piezoceramics have a higher quality factor Qm, a higher safe operating temperature (Curie temperature), and lower dielectric loss (tanδ).

Performance of piezoelectric ceramics under low electric field conditions

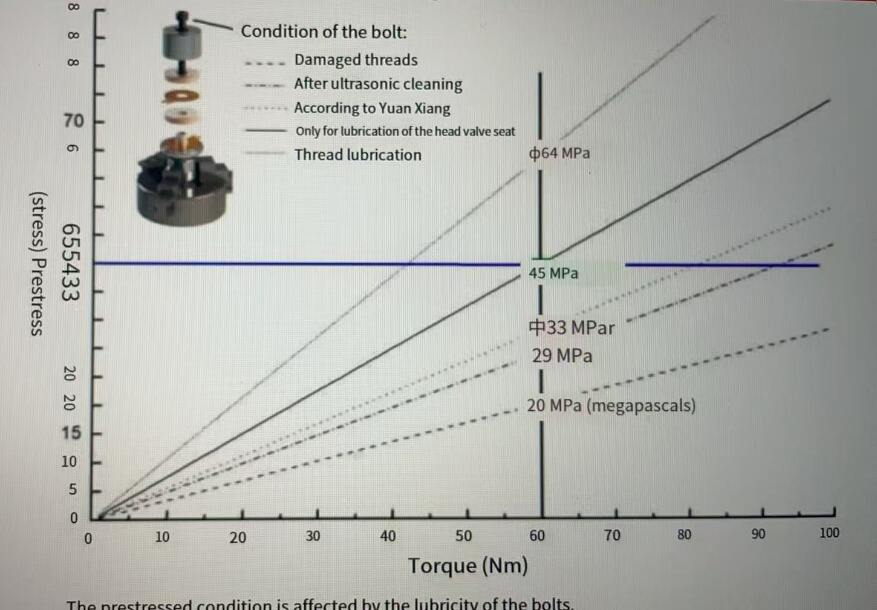

Transducer manufacturing core

Due to the weak tensile strength of piezoceramics, when the transducer undergoes ultrasonic vibration, static compressive preload must be applied to prevent the piezoceramic from experiencing tensile stress. Additionally, the preload ensures good contact at the piezoceramic interfaces, allowing sound waves to transmit with minimal loss. The compressive preload must be sufficient to prevent the piezoceramic from undergoing ultrasonic tensile stress and to prevent lateral slippage of the piezoceramic. The magnitude of the preload during the fabrication of ultrasonic transducers plays a decisive role in quality.

After tightening the prestressed bolts, prestress can be applied to the piezoceramic material. Traditionally, a torque wrench is used to set a specific torque value before tightening the prestressed bolts; however, this parameter is influenced by many factors and often results in deviations. Even when using the same torque, the lubrication level of the bolts and the front and rear drivers affects the magnitude of the prestress applied to the ceramic plates.

prestressed condition is affected by the lubricity of the bolts.

The impact of prestressing on transducers

The impedance and frequency of piezoceramics stabilize as preload increases. Higher preload can reduce the impedance of the transducer. If the piezoceramic is not adequately clamped, the transducer impedance will increase.

Is it true that the prestress of the transducer should be as high as possible?

Excessive prestress can reduce the performance of the transducer, mainly reflected in the following aspects:

1.The performance of piezoceramics changes under compressive bias. Specifically, the highest safe operating temperature for the material may significantly decrease, and high compressive stress may lower the Curie temperature.

2.Excessive preload can lead to significant depolarization, while also causing unstable impedance and aging.

3.Excessive prestress can reduce the lifespan of the transducer, and in severe cases, it may cause cracking of the ceramic plates in the transducer.

4.Initially, excessive prestress in the transducer may result in lower impedance, but over time, the performance of the transducer deteriorates, accompanied by products exhibiting high impedance.

HCSONIC transducer manufacturing

We fixed the transducer on the workbench, then connected the positive and negative electrodes of the electrode plate to the dedicated equipment. After inputting the corresponding parameters, we used a specific wrench to tighten the prestressed bolts. When the prestress reaches the required value, the device will prompt to stop working, thereby producing high-quality ultrasonic transducers suitable for various working environments. Ultrasonic transducers are the main core components in making ultrasonic devices.

We can customize various transducers of different frequencies based on customer needs, with frequency ranges from 15kHz to 120kHz, used for ultrasonic welding, ultrasonic cutting, ultrasonic mist spraying, and ultrasonic sonochemical liquid treatment, among other applications. HCSONIC ultrasonic transducers offer one year of warranty service.