Как Ультразвуковой преобразователь Технология позволяет применять ее с точностью

При частотах, превышающих 20 кГц, ультразвуковые преобразователи преобразуют электрическую энергию в высокочастотные механические вибрации. Этот диапазон частот обеспечивает точность работы и предотвращает помехи с окружающими звуковыми сигналами, что делает его идеальным для чувствительных промышленных и медицинских условий.

Что такое ультразвуковой преобразователь?

Ультразвуковой преобразователь - это датчик, который преобразует электрические сигналы в целевые звуковые волны. Когда эти волны взаимодействуют с материалами, они производят измеримую обратную связь, используемую для измерения расстояния, обнаружения дефектов или физической модификации без контакта или повреждения поверхности. Эта неинвазивная способность является основой для его использования в критически точных системах.

Основные принципы работы ультразвукового преобразователя

Эти устройства используют пиезоэлектрические кристаллы, которые вибрируют при нагнетании, создавая волны давления, которые распространяются через твердые вещества, жидкости или газы. Работая на резонансных частотах, преобразователи усиливают интенсивность волны посредством конструктивных помех, что позволяет контролировать микроскопический уровень. Этот принцип имеет основополагающее значение для применений, требующих точности до миллиметра.

Типы ультразвуковых преобразователей, используемых в промышленном применении

- Пезоэлектрические преобразователи доминируют в промышленном окружении из-за их высокой чувствительности в обнаружении субмиллиметровых дефектов

- Магнитостриктивные преобразователи предпочтительны для высокопроизводительных применений, таких как резка металлов, использование ферромагнитных материалов деформации

- Электростатические преобразователи позволяет очищать микроэлементы с помощью емкостного привода диафрагмы, подходящего для деликатных компонентов MEMS

Технологический прогресс повышает эффективность ультразвуковых преобразователей

Современные композитные материалы, такие как керамика PZT-8, повышают эффективность преобразования энергии на 38% по сравнению с традиционным кварцем. Адаптивные алгоритмы частотной настройки противодействуют акустическому заглушению в вязких средах, повышая производительность в медицинской стерилизации. Цифровая формация луча фокусирует вибрационную энергию в 0,5 мм пятна, что позволяет бесконтактную гравировку и очистку полупроводников с исключительным пространственным управлением.

Ультразвуковые преобразователи в прецизионной очистке: механизмы и применения

Кавитационная динамика: наука ультразвуковой очистки

Ультразвуковая очистка работает главным образом благодаря чему-то, что называется кавитация. В основном, он использует высокозвуковые звуковые волны, которые мы даже не слышим, обычно от 20 до 130 килогерц, чтобы создать крошечные пузыри в любой жидкости, которую они используют. Далее происходит очень интенсивное. Эти маленькие пузыри становятся больше, а затем быстро взрываются, создавая небольшие ударные волны, которые сбивают грязь и грязь с поверхности. Для достижения наилучших результатов, техники должны сопоставить настройки машины с так называемой резонансной частотой резервуара. Когда это происходит, образуется больше пузырей, которые взрываются с нужным количеством силы, чтобы тщательно очистить вещи, не повреждая их.

Как ультразвуковые преобразователи помогают очищать микроскопические объекты

Преобразуя электрический вход в механические вибрации (45130 кГц), ультразвуковые преобразователи производят кавитационные пузыри, способные проникать в субмикронные трещины. Это позволяет удалять загрязняющие частицы размером до 0,1 мкм из сложных геометрических структур, таких как капилляры и микрофлюидные каналы, превосходя ручную очистку на 85% в условиях высокой точности.

Основные применения в полупроводниковом, медицинском и электронном производстве

- Полупроводник : очищает фоторезистентные остатки на наномасштабе от пластинок без повреждения функций микросхемы

- Медицинский : достигает 99,98% биофильма ликвидации на хирургических инструментах, подтвержденных по протоколам FDA

- Электроника : Удаление остатков потока из компонентов размером 0201 при сохранении целостности соединительного сплава

Эта универсальность поддерживает расширение рынка высокоточной очистки, который, по прогнозам, достигнет $3,9 млрд к 2035 году (Отчет о рынке ультразвукового очистного оборудования 2025 ).

Ультразвуковые и традиционные методы очистки: производительность и эффективность

| Метрический | Ультразвуковая очистка | Традиционные методы |

|---|---|---|

| Удаление загрязнителей | Подмикронный | > 10 мкм эффективно |

| Время обработки | 3–5 минут | 15–30 минут |

| Потребление химических веществ | Снижение на 78% | Большие ванны |

| Покрытие сложных частей | Полный доступ на 360° | Теневые зоны остаются |

Ультразвуковые системы обеспечивают на 40% более высокую пропускную способность без механического износа, исключая переработку и соответствующие стандартам ISO 13485 и IPC по чистоте и проверке процесса.

Ультразвуковые преобразователи в области прецизионной резки и обработки материалов

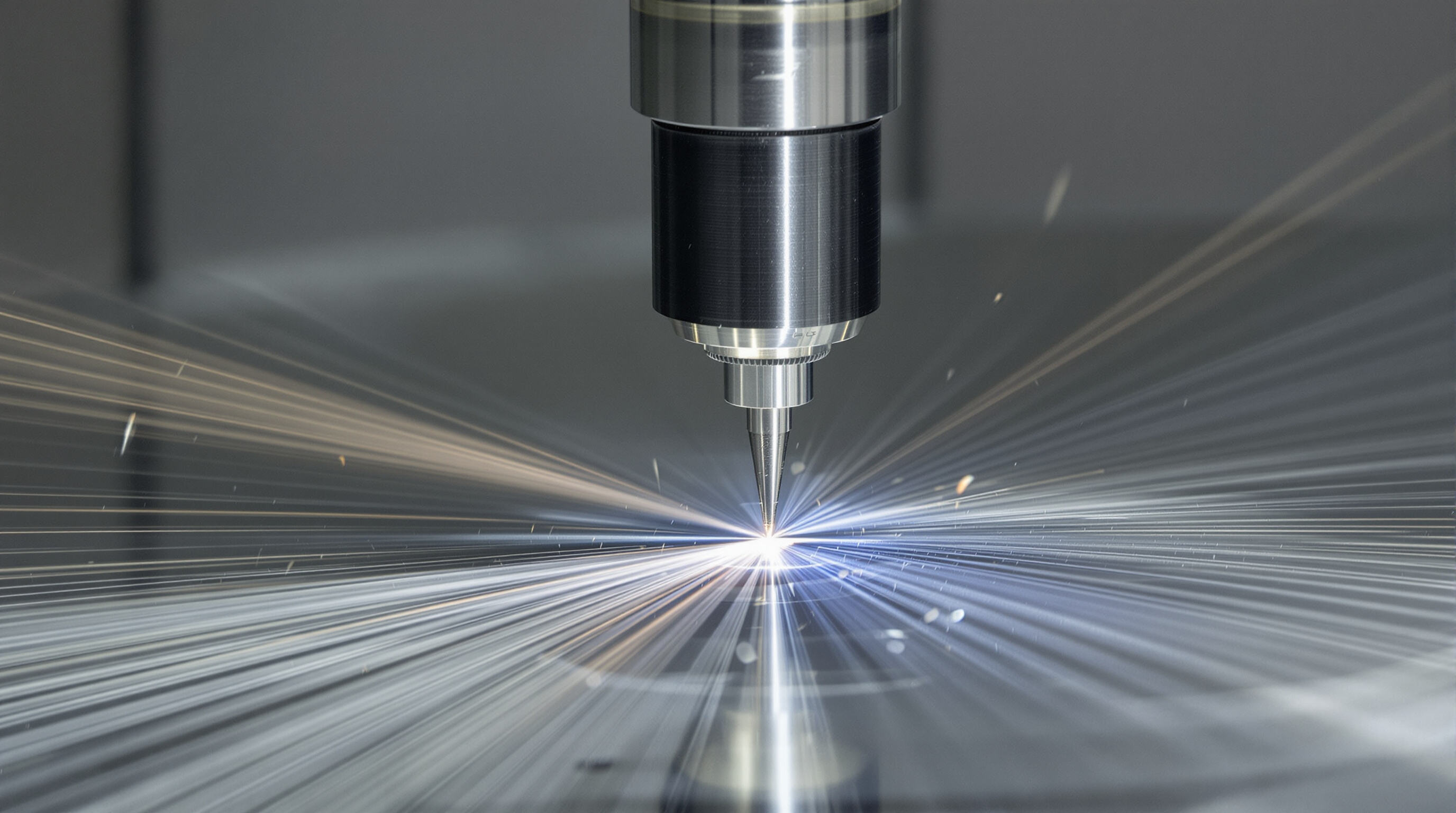

Механизмы ультразвуковой резки и обработки

Ультразвуковые преобразователи работают на высокоточном станке, превращая электрическую энергию в механические вибрации от 20 до 40 кГц, которые создают около 100 тысяч крошечных ударов каждую секунду прямо на конце инструмента. Когда эти быстро движущиеся вибрации попадают в материал, они в основном начинают создавать небольшие трещины на поверхности, что сокращает силу, необходимую при процессе резки примерно на 60 процентов, если сравнивать с стандартными методами. Поскольку таким образом создается меньше трения и тепла, производители могут обрабатывать очень детальные элементы в жестких материалах, таких как аэрокосмические металлы и эти деликатные оптические части, не беспокоясь о деформации от теплового повреждения.

Преимущества обработки нежных и труднорезаемых материалов

Эта технология очень хорошо работает при работе с материалами, которые либо хрупкие, либо чувствительны к изменениям температуры. Согласно различным испытаниям, с помощью ультразвуковой обработки можно уменьшить деформацию материала примерно на 30 процентов или больше. Это позволяет делать чистые разрезы через композитные материалы из углеродного волокна без разделения слоев и точно формировать оптическое стекло без создания крошечных трещин. По сравнению с лазерными или плазменными методами, ультразвуковые методы фактически поддерживают структурную целостность таких вещей, как биомедицинские полимеры и аэрогели. Плюс есть еще одно преимущество, которое стоит упомянуть. Вибрационное удаление чипа помогает инструментам продержаться дольше.

Тема исследования: Ультразвуковое резка в медицинской имплантации

Недавно один из крупнейших производителей ортопедии начал использовать ультразвуковые преобразователи при изготовлении титановых имплантатов, и они получили почти идеальные результаты с точностью 99,8% на эти крошечные 500-микронные детали. Этот подход особенен тем, что не генерирует тепло, поэтому нет проблемных участков, где металл повреждается во время производства. Это очень важно, потому что эти пористые титановые части должны работать с костями со временем. Компания обнаружила, что они могут сократить все дополнительные работы по отделке примерно на 70%, что экономит время и деньги. Если посмотреть на качество поверхности, их процесс создает поверхности примерно на 0,1 микрона, что намного лучше, чем то, что обычно получают лазеры на 1,5 микрона. Этот уровень гладкости действительно помогает имплантатам функционировать внутри тела, особенно важно для таких устройств, как спинальные синтезаторы, где совместимость с живой тканью имеет решающее значение.

Расширение возможностей: от очистки до передового формирования материалов

Помимо очистки, ультразвуковые преобразователи теперь позволяют создавать более совершенные формы материалов. Инновации включают:

- Ультразвуковая 3D-печать с применением полимеров, усиленных наночастицами

- Гравировка недра в кристаллических материалах с использованием фокусированных вибрационных полей

- Ламинированные композитные формования с встроенными массивами преобразователей

Эти разработки особенно ценны в производстве квантовых устройств, где обычные тепловые или механические методы рискуют декогеренцией в чувствительных субстратах.

Тенденции рынка и факторы роста в отрасли ультразвуковых преобразователей

Увеличивается спрос на высокоточную очистку в высокотехнологичном производстве

Производители полупроводников, медицинских устройств и электроники требуют микронизовой чистоты, чтобы предотвратить функциональные сбои. Ультразвуковые преобразователи предлагают альтернативные средства для традиционных ванн, которые все чаще интегрируются в автоматизированные линии. Их способность удалять частицы до микрона улучшает урожайность и уменьшает отходы, что способствует их применению в чистых помещениях.

Влияние автоматизации и миниатюризации на использование ультразвуковых преобразователей

По мере сокращения комплектующих и увеличения производства растет спрос на микрочистительные решения. Миниатюрные датчики и микроэлектроника требуют методов очистки, которые достигают сложных характеристик, достижимых только с помощью оптимизированной кавитации. Автоматизированные ультразвуковые системы сокращают время цикла на 40% по сравнению с ручными процессами, обеспечивая повторяемость в производстве больших объемов.

Региональные тенденции рынка и промышленные инвестиции в ультразвуковые системы

Азиатско-Тихоокеанский регион действительно лидирует в плане инвестиций, на него приходится примерно половина (около 55%) всех установки преобразователей, происходящих прямо сейчас в тех крупных центрах электроники и полупроводников, которые мы видим в таких местах, как Тайвань и Южная Корея. В Северной Америке в последнее время наблюдается значительный подталкивающий эффект от улучшения производства медицинских изделий. Между тем, европейские страны делают упор на чистоту для частиц, использующих возобновляемые источники энергии, особенно таких, как топливные элементы и солнечные панели. Если посмотреть на то, что происходит во всем мире с этими усилиями по модернизации промышленности, то, кажется, в ультразвуковые системы вкладывается примерно на 30% больше денег, чем в старые технологии. Это имеет смысл, учитывая, насколько они лучше работают во многих приложениях.

Перспективы будущего: интеграция с умным производством и Интернетом вещей

Сближение с промышленностью 4.0 позволит внедрить ультразвуковые преобразователи в сети Интернета вещей. Алгоритмы прогнозирования обслуживания будут контролировать состояние пиезоэлектрических кристаллов, а управляющие ИИ динамически регулируют частоты на основе обратной связи материала. Это позволяет создавать автономные, энергоэффективные циклы очистки и дистанционную диагностику, продвигая отрасль к нулевым дефектам, самооптимизирующимся производственным средам.

Часто задаваемые вопросы

Какой диапазон частот ультразвуковых преобразователей?

Ультразвуковые преобразователи работают на частотах выше 20 кГц, что выше, чем у человека. Они могут работать до 130 кГц, в зависимости от применения.

Какую пользу при чистке приносят ультразвуковые преобразователи?

Ультразвуковые преобразователи создают кавитационные пузыри посредством механических вибраций, которые проникают в субмикронные трещины, чтобы удалять загрязнители без повреждения поверхностей.

Могут ли ультразвуковые преобразователи использоваться при изготовлении медицинских имплантатов?

Да, ультразвуковые преобразователи используются при изготовлении медицинских имплантатов, обеспечивая точную резку без получения тепла, что предотвращает повреждение материала.

Как региональные тенденции на рынке влияют на ультразвуковые системы?

Азиатско-Тихоокеанский регион лидирует в инвестировании в ультразвуковые системы из-за производства электроники, в то время как Северная Америка фокусируется на медицинских устройствах, а Европа - на чистых возобновляемых энергетических частях.

Содержание

- Как Ультразвуковой преобразователь Технология позволяет применять ее с точностью

- Ультразвуковые преобразователи в прецизионной очистке: механизмы и применения

- Ультразвуковые преобразователи в области прецизионной резки и обработки материалов

-

Тенденции рынка и факторы роста в отрасли ультразвуковых преобразователей

- Увеличивается спрос на высокоточную очистку в высокотехнологичном производстве

- Влияние автоматизации и миниатюризации на использование ультразвуковых преобразователей

- Региональные тенденции рынка и промышленные инвестиции в ультразвуковые системы

- Перспективы будущего: интеграция с умным производством и Интернетом вещей

- Часто задаваемые вопросы