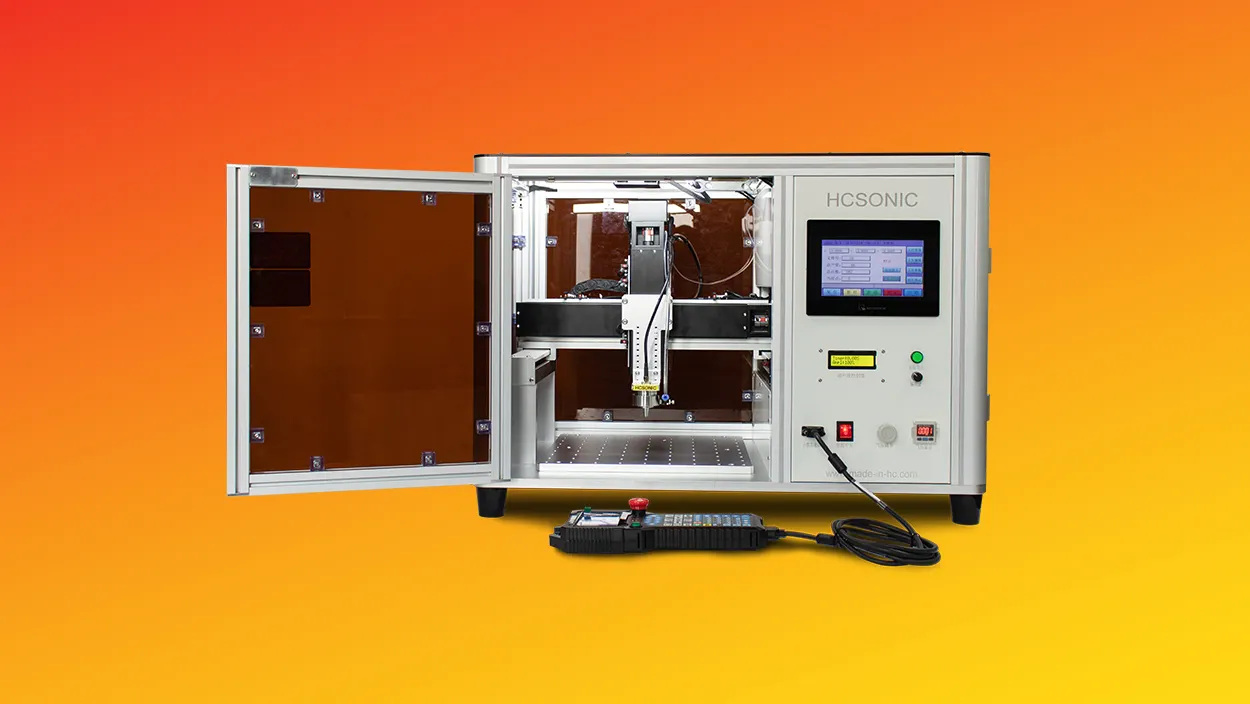

Product Description

Ultrasonic spraying equipment, as a more accurate, easier to manipulate and more environmentally friendly spraying technology, will replace traditional second-fluid spraying. Additionally, because this spraying does not clog or wear, it can also contribute to reducing downtime during key manufacturing processes. "HCSONIC" ultrasonic spraying equipment, with its gentle spraying characteristics, greatly reduces over-spraying, thereby reducing costs and pollution to surrounding air. At the same time, this new technology has also expanded more application areas, for example, it is ideal when required to spray low flow. For substrate spraying, atomization and humidification, film coating, spray drying, flux spraying, film spraying, thin wire spraying and other ind.

Introduction to Ultrasonic Mist Spraying:

Ultrasonic spray coating equipment is widely applied in industrial and research and development fields. Due to environmental factors and excessive pollution, scientists, engineers, and designers have adopted ultrasonic spraying equipment. As a more precise, easier-to-control, and environmentally-friendly spraying technology, ultrasonic spraying equipment will replace traditional two-fluid spraying. Additionally, because this spraying method does not clog or wear out, it also contributes to reducing downtime in critical manufacturing processes.

The ultrasonic spray coating equipment from 'HCSONIC', with its gentle mist characteristics, significantly reduces over-spraying, thereby lowering costs and minimizing air pollution. This new technology also expands into more application areas, such as being ideal for low-flow spraying requirements. For substrate spraying, atomized humidification, thin film coating, spray drying, flux spraying, membrane spraying, fine line spraying, and other industrial and research and development applications, the ultrasonic spray coating equipment from 'HCSONIC' produces better results than other technologies.