- Overview

- Recommended Products

Product Description

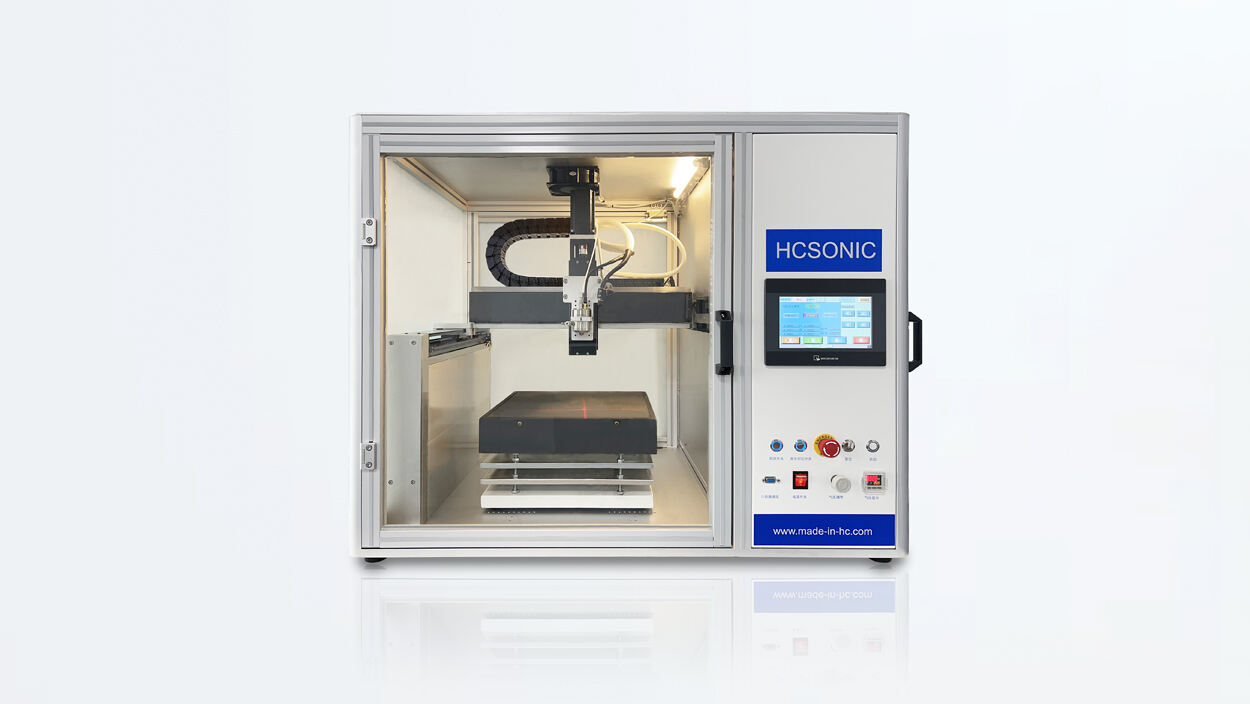

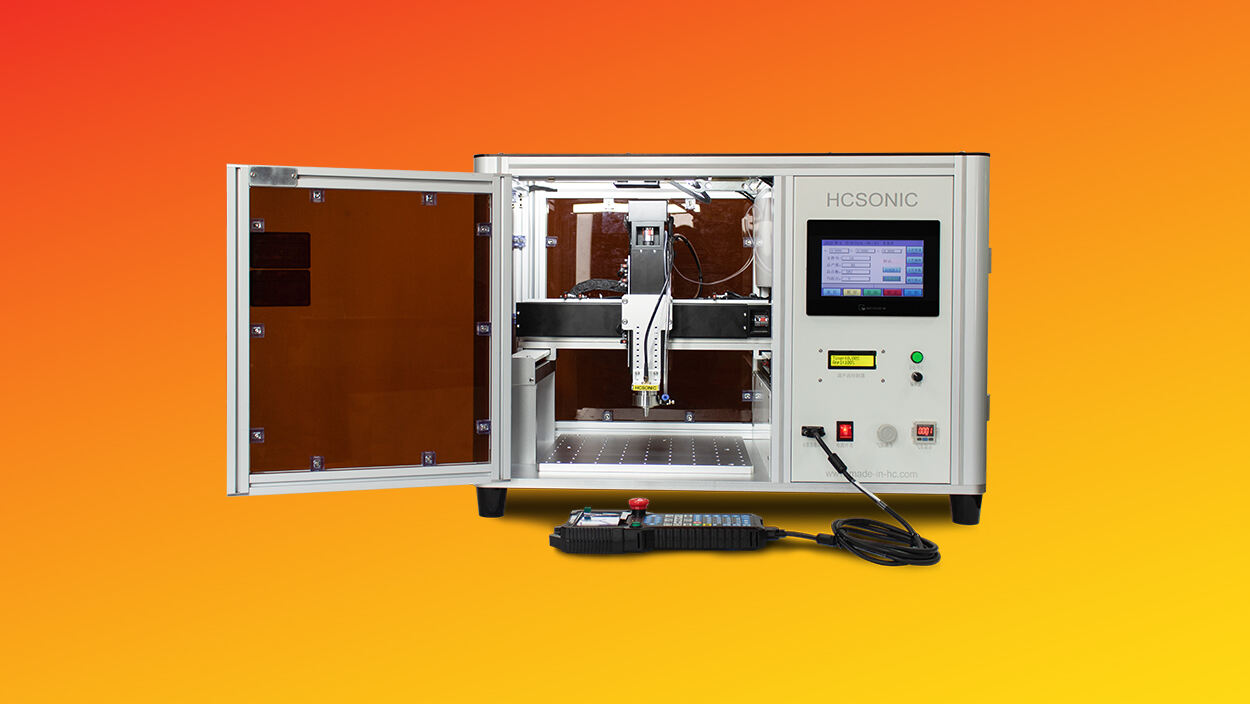

Ultrasonic spraying equipment, as a more accurate, easier to manipulate and more environmentally friendly spraying technology, will replace traditional second-fluid spraying. Additionally, because this spraying does not clog or wear, it can also contribute to reducing downtime during key manufacturing processes. "HCSONIC" ultrasonic spraying equipment, with its gentle spraying characteristics, greatly reduces over-spraying, thereby reducing costs and pollution to surrounding air. At the same time, this new technology has also expanded more application areas, for example, it is ideal when required to spray low flow. For substrate spraying, atomization and humidification, film coating, spray drying, flux spraying, film spraying, thin wire spraying and other ind.

Introduction to Ultrasonic Mist Spraying:

Ultrasonic spray coating equipment is widely applied in industrial and research and development fields. Due to environmental factors and excessive pollution, scientists, engineers, and designers have adopted ultrasonic spraying equipment. As a more precise, easier-to-control, and environmentally-friendly spraying technology, ultrasonic spraying equipment will replace traditional two-fluid spraying. Additionally, because this spraying method does not clog or wear out, it also contributes to reducing downtime in critical manufacturing processes.

The ultrasonic spray coating equipment from 'HCSONIC', with its gentle mist characteristics, significantly reduces over-spraying, thereby lowering costs and minimizing air pollution. This new technology also expands into more application areas, such as being ideal for low-flow spraying requirements. For substrate spraying, atomized humidification, thin film coating, spray drying, flux spraying, membrane spraying, fine line spraying, and other industrial and research and development applications, the ultrasonic spray coating equipment from 'HCSONIC' produces better results than other technologies.

Product Details

The principle of ultrasonic atomization spraying

Ultrasonic spray coating utilizes the piezoelectric effect to convert electrical energy into high-frequency mechanical energy, thereby atomizing liquids. By using ultrasonic high-frequency oscillation, liquids are atomized into uniform micrometer-sized particles. Compared to traditional pressure-based nozzles, ultrasonic spraying can achieve more uniform, thinner, and more controllable thin-film coatings, and is less prone to nozzle clogging. Since ultrasonic nozzles require only kilopascal-level micro air volume, there is almost no splashing during the spraying process, resulting in a paint utilization rate of over 90%.

Ultrasonic spraying is a successful technology, for example, for high-quality and high-performance coating on substrates. By precisely controlling various process parameters of ultrasonic spraying, over-spraying can be avoided, achieving accurate droplet distribution. The advantages of ultrasonic spraying include precise control of droplet size, spray intensity, and liquid flow rate.

Types of ultrasonic nebulizing nozzles

--Micro ultrasonic atomizing nozzle

The micro-ultrasonic atomization nozzle system integrates HCSONIC focused ultrasonic nozzles, multi-channel liquid injection tubes, and low-pressure guiding carrier gas. The combination of these elements produces a gentle, highly focused mist beam.

--Intrusive ultrasonic mist nozzle

The intrusive ultrasonic atomizing nozzle system can produce different sizes of atomized particles and spraying widths through various frequency and airflow channel designs, adapting to different area, thickness, smoothness, and other spraying requirements. Additionally, its unique structural design allows it to be suitable for special applications such as high temperatures and narrow spaces.

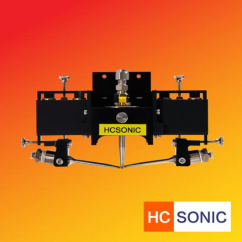

--Convergent ultrasonic nebulizing nozzle

The convergent-type ultrasonic atomization nozzle system combines low-pressure gas with HCSONIC's unique micro-atomizing ultrasonic nozzles to produce gentle and highly focused mist beams. When compressed gas is introduced into the air diffusion chamber within the gas shroud, it generates a consistent and evenly distributed airflow around the nozzle surface. The spray produced by the ultrasound immediately forms a spray stream. There is an adjustable focusing device on the gas shroud that provides complete control over the width of the spray.

--Vortex ultrasonic atomizing nozzle

The vortex-type ultrasonic atomizing nozzle system utilizes HCSONIC's unique cavity design to generate a wide and stable spray beam through rapid rotating airflow. By adjusting the distance between the atomizer head and the workpiece, the vortex nozzle can produce adjustable diameter conical spray beams.

--Mouth-shaped ultrasonic nebulizing nozzle

Wide-mouth ultrasonic mist nozzles use low-pressure air/gas to produce uniform wide mist bands, with a maximum spray width of up to 25 centimeters, suitable for fan-shaped area spraying.

--Fan-shaped wide spray ultrasonic atomizing nozzle

The conical wide spray ultrasonic nozzle system combines HCSONIC's unique ultrasonic atomizing nozzle with the controlled airflow of a conical nozzle. The droplets produced by the ultrasonic waves on the atomization surface are immediately carried away by the airflow, forming a conical spray pattern. Due to the controlled airflow speed, the airflow can impact the spray onto the product or workpiece with either high or low force.

--High-temperature pyrolysis ultrasonic atomizing nozzle

The high-temperature pyrolysis ultrasonic atomization nozzle system combines low-pressure gas with HCSONIC's unique ultrasonic atomizing nozzles. It is made from materials that can withstand high temperatures. One characteristic of the high-temperature pyrolysis atomization nozzle is its ability to operate continuously in high-temperature environments. It is important to note that at high temperatures, molecular activity increases significantly, and the dust in the flue gas becomes highly aggressive, leading to greater wear on the high-temperature atomization nozzles. Therefore, it is necessary to select appropriate materials based on the solution being atomized.

Additional features

Ultrasonic pre-dispersion system

Ultrasonic dispersion injector, which can achieve ultrasonic dispersion treatment of the solution before atomization spraying, avoiding sedimentation of solids during the spraying process.

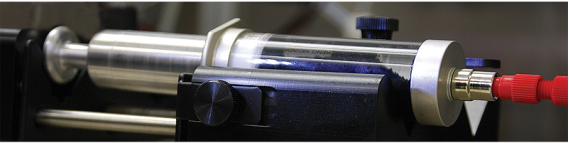

pre-dispersion syringe

liquid transfer pump

Ultrasonic mist spraying equipment can be used with various liquid delivery systems, such as syringe pumps, gear pumps, peristaltic pumps, pressure tanks, etc. Regardless of which system is used, as long as the liquid is delivered at a stable flow rate within the nozzle's working range, any of these systems will function. However, pulsation should be avoided (syringe pumps are recommended), as even momentary pulses may cause the liquid to fall outside the operational range. This is particularly evident in low-flow applications such as stent coating.

Factors affecting ultrasonic spraying

droplet size:

The frequency of ultrasonic spray equipment affects the size of droplets; the higher the frequency, the smaller the droplet size. At 20 kHz, the median droplet size is 90 micrometers, while at 40 kHz, the droplet size further reduces to an average of 45 micrometers.

The success or failure of nebulization:

If the ultrasonic energy is too high, cavitation will occur. Excessive energy will not form an ideal thin film at the nozzle tip, causing the liquid passing through the nozzle to atomize prematurely and 'tear' into droplets of varying sizes. Only the amplitude generated at a specific power level can produce relatively ideal atomization effects. For ultrasonic atomization spraying, the input power level is generally around 10 to 15 watts.

aerosol flow:

The flow range of ultrasonic atomizing nozzles is generally quite large, unlike traditional air-driven nozzles that rely on the force of air to break down liquid streams for atomization. Therefore, the amount of liquid atomized by the nozzle per unit time mainly depends on the liquid delivery system used in conjunction with the atomizing nozzle.

liquid compatibility:

Various coatings, chemicals, lubricants, and particulate suspensions can be easily atomized. However, factors such as viscosity, miscibility, and solid content should be considered. To achieve optimal atomization, the viscosity should be below 40 cps, and the solid concentration should remain under 30%. Since the ultrasonic atomization spraying process relies on the movement of a liquid film, generally, the higher the viscosity of the liquid, the more difficult it is to atomize. Liquids containing long-chain polymer molecules have higher cohesion, making them hard to atomize even when diluted. Typically, mixtures of single particles are easier to atomize.

--ordinary pure liquid

Pure single-component liquids (water, alcohol, bromine, etc.)

polymers/water,silica/alcohol, suspensions, etc.).

Carry non-soluble solid mixtures (coal slurry, bead-like polymers/water, silica/alcohol, suspensions, etc.).

For pure liquids, the only factor affecting atomization is viscosity, which typically does not exceed around 10 centipoise.

--polymer molecular liquid

Pure solutions generally resemble pure liquids under most circumstances, except when the solvent contains long polymer molecule chains. In such cases, the length of the polymer molecules affects the atomization process, as these polymer molecules hinder the formation of discrete droplets when they separate from the entire liquid and subsequently form an aerosol.

--insoluble solid mixture

A mixture containing insoluble solids has three factors that affect its atomization capability: particle size, solid concentration, and the dynamic relationship between solid particles and the carrier.

The concentration of solid particles is crucial, with an upper limit of approximately 30%. At higher concentrations, appropriate conditions are required for atomization. Lastly, even if the particle size is suitable, the feasibility of liquid atomization is influenced by other dynamic factors such as the viscosity of the carrier and the ability of the solid components to remain suspended.

If the particle size exceeds one-tenth of the median droplet size, the mixture generally atomizes easily. For droplets containing one or more solid particles, the droplet size must be significantly larger than the solid particles; otherwise, most droplets are unlikely to contain the solid particle components, leading to separation.

The differences between ultrasonic mist nozzles and traditional nozzles

Unlike traditional nozzles that rely on pressure and high-speed motion to break liquids into small particles, ultrasonic nozzles use lower ultrasonic vibration energy for liquid atomization. The liquid can be delivered to the nozzle by its own gravity or a low-pressure pump, achieving continuous or intermittent atomization. Within limits, the amount of liquid atomization is solely determined by the delivery rate of the liquid.

Traditional two-fluid nozzle:

Utilizing the kinetic energy of two fluids, gas and liquid, for atomization.

The spray has significant impact force, which can cause splashing and waste of raw materials.

The uniformity of the aerosol particles is poor.

The size of the aerosol particles is determined by the nozzle diameter.

When the nozzle opening is very fine, it is prone to clogging the nozzle.

Unable to precisely control the spray flow rate, unable to sustain spraying at lower flow rates

Two-fluid nozzle

HCSONIC ultrasonic nebulizing nozzle:

Using high-frequency ultrasound oscillation to atomize liquids.

The spray impact force is very small, so it will not cause splashing or waste of raw materials.

The uniformity of the aerosol particles is very high.

The size of the aerosol particles is determined by the ultrasonic frequency and is unrelated to the nozzle diameter.

The nozzle diameter can be adjusted, and it maintains ultrasonic oscillation, making it less prone to clogging.

It can precisely control the flow rate and continue to spray at extremely low flow rates.

HCSONIC ultrasonic nebulizing nozzle

What are the advantages of ultrasonic mist spraying?

--The sprayed pattern is easy to shape and suitable for precise coating applications.

--Spray coating can be applied to objects of any shape, resulting in an even micron-thick layer.

--Ultrasonic mist spraying can reduce downtime in critical production processes.

--Ultrasonic mist spraying has an extremely low flow rate and can operate intermittently or continuously.

--Highly controllable spray volume, ensuring more reliable spraying quality.

--Low energy consumption, high atomization efficiency, and minimal restrictions on the atomized liquid.

--It can reduce waste and air pollution caused by backfire, saving costs.

--No stress, no noise, no wear of moving parts, no blockages.

--The atomizing nozzle is made of titanium material, featuring high strength and strong corrosion resistance.

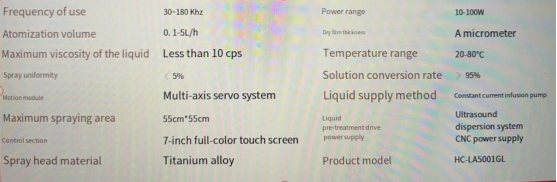

Product specifications: