- Overview

- Recommended Products

Product Description

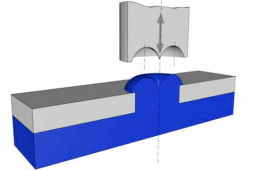

Ultrasonic mask welding machine uses high-frequency vibration waves to transmit to the surfaces of two objects that need to be welded. Under pressure, the surfaces of the two objects rub against each other to form fusion between molecular layers. Some indentation marks can be seen everywhere on the mask, such as edge seals, ear straps, and exhalation valves, which are ultrasonic welded. As shown in the figure above, during the production process of masks, we can intuitively understand the welding of all-plastic nose bridge strips, folded edge welding, breathing valve welding, multi-layer roller welding, and ear belt welding. These are actually completed through ultrasonic welding process.

Product Details

Ultrasonic mask welding machine

Ultrasonic mask welding machine utilizes high-frequency vibration waves transmitted to the surfaces of two objects to be welded. Under pressure, the surfaces of the two objects rub against each other, causing molecular fusion between them.

On masks, one can observe numerous weld marks, such as at the edges, ear loops, and exhalation valves, which are all created through ultrasonic welding. As shown in the diagram, during the production process of masks, we can clearly see the full plastic nose bridge welding, edge welding after folding, breathing valve welding, multi-layer rolling welding, and ear loop welding. All these processes are accomplished using ultrasonic welding technology.

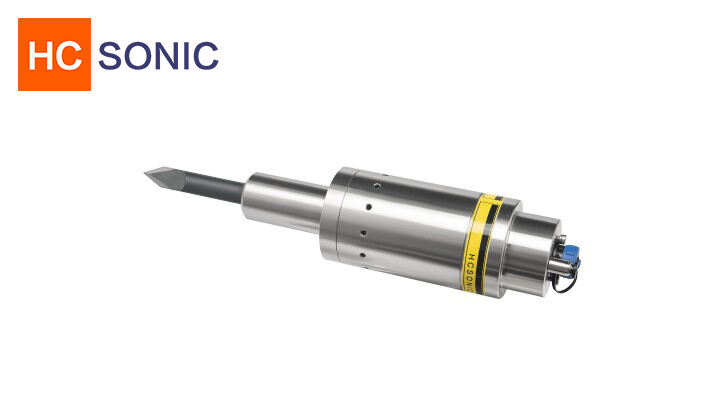

When ultrasonic waves act on the contact surfaces of thermoplastic plastics, they generate high-frequency vibrations several tens of thousands of times per second. This high-frequency vibration, when reaching a certain amplitude, transmits ultrasonic energy to the weld area through the upper workpiece. Due to the high acoustic impedance at the weld interface where the two parts to be welded meet, local high temperatures are produced. Additionally, because plastics have poor thermal conductivity, the heat cannot dissipate quickly, causing it to accumulate in the weld area, which rapidly melts the contact surfaces of the two plastics. Under a certain pressure, they fuse into one piece.

Ultrasonic welding process.

The process of ultrasonic welding involves maintaining pressure for several seconds after the ultrasonic waves cease, allowing it to solidify and form a robust molecular chain, thus achieving the purpose of welding. The strength of the weld can approach that of the raw material. Ultrasonic welding can be categorized into different methods based on the welding technique, including insert welding, rivet welding, spot welding, and forming.

Ultrasonic welding uses high-frequency vibrations between 15 kHz and 50 kHz to melt and weld plastics. The upper and lower parts are clamped together, and the ultrasonic vibration is transmitted to the connection point of the upper and lower parts, causing alternating stress at the weld seam. This generates heat through friction between the molecules, melting the plastic. Once the ultrasonic vibration stops, the upper and lower parts continue to remain clamped until they bond together.

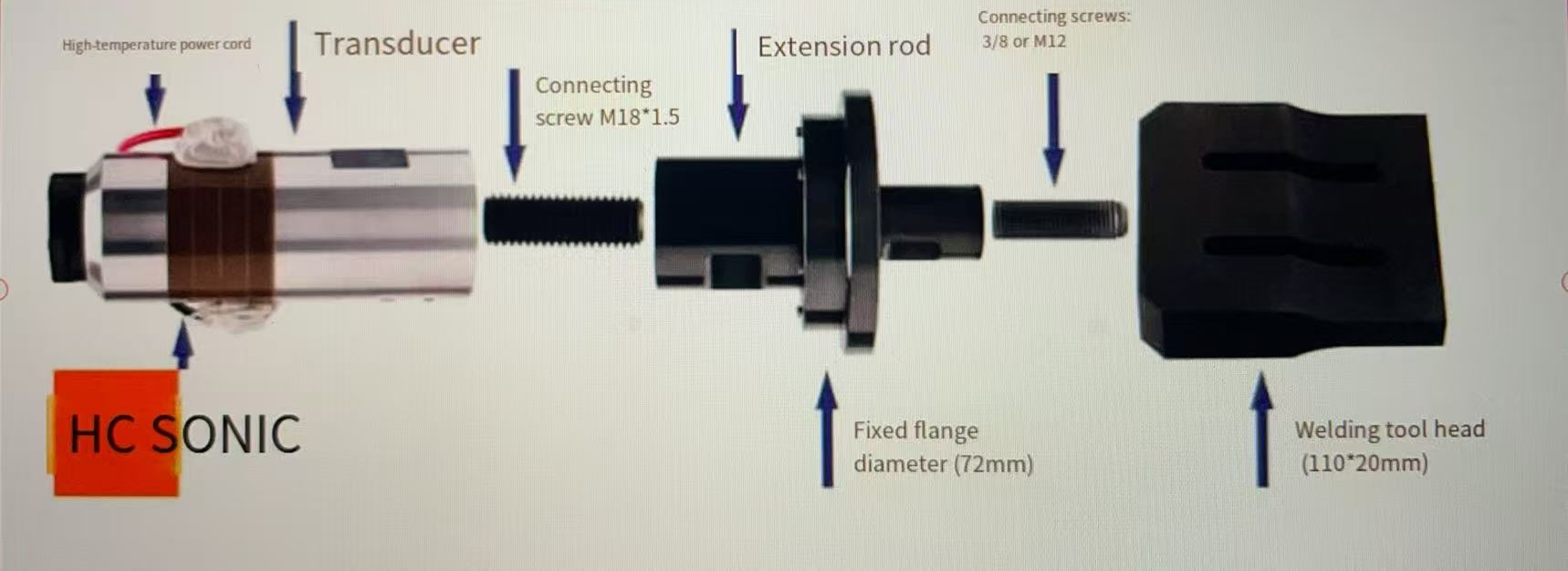

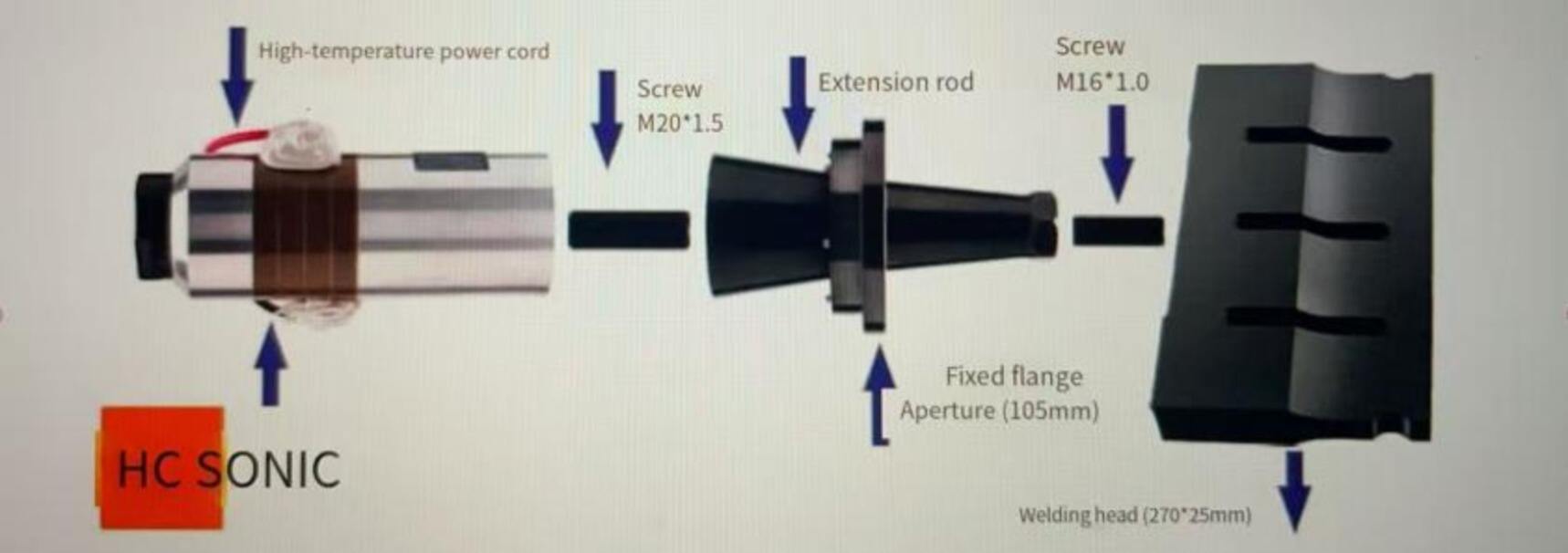

Ultrasonic mask welding machine components:

Ultrasonic generator (power source):

The ultrasonic generator converts power current of 110VAC or 220VAC into high-frequency high-voltage electrical signals. HCSONIC ultrasonic generators have the following advantages:

Locking primary resonance: All ultrasonic systems have a primary resonance (ideal working resonance), along with secondary (false) resonances. Upon power startup, the HCSONIC ultrasonic generator locks onto the primary resonance while ignoring secondary resonances.

Tracking primary resonance: During ultrasonic operation, the frequency of the primary resonance may shift. As the stack temperature increases, this frequency may decrease due to internal losses or heat transferred from the load. The ultrasonic generator can automatically track this frequency shift, ensuring stable operation.

Automatic amplitude adjustment: The HCSONIC ultrasonic generator achieves optimal control by regulating the output amplitude, allowing for adjustments based on the thickness of the materials being welded. This ensures that the same welding process can effectively weld both standard medical masks and KN95 professional masks.

Ultrasonic transducer

Ultrasonic transducers utilize high-frequency electrical signals from ultrasonic generators and convert them into linear mechanical motion. This conversion is achieved through the use of piezoelectric ceramic disks, which expand when voltage is applied. Transducers used for ultrasonic rubber cutting are specially designed to allow the intake and outflow of air for cooling purposes.

Ultrasonic booster (amplifier):

The ultrasonic horn is an adjustable component that mechanically regulates the displacement of the linear vibration from the transducer to the required level for specific applications, thereby achieving optimal cutting performance. Additionally, the ultrasonic horn provides a safe, non-vibrating location where it can be installed on welding equipment or production lines.

Ultrasonic welding horn (tool head):

Ultrasonic welding tool heads are custom tools designed to vibrate at specific frequencies. These tools are meticulously designed using computer modeling techniques to achieve optimal performance and longevity. The ultrasonic welder head must be tuned to match the system's frequency. This tuning process requires consideration of the tool head's mass, length, and geometry. HCSONIC offers various configurations, each tailored for specific applications, ensuring excellent long-term usage performance.

Ultrasonic mask welding machine (20K) power 2000W:

Ultrasonic mask welding machine (15K) power 2600W:

Ultrasonic mask ear loop sealer (35K)