- Overview

- Recommended Products

Product Description

The main function of the ultrasonic plastic cutting process is to split the connected parts, and the pressure acting on the items to be cut can be reduced through high-frequency vibration per second, so as to facilitate the formation of a neat and clean cutting surface. Ultrasonic plastic cutting uses the energy of ultrasonic waves to locally heat and melt the cut plastic, thereby achieving the purpose of cutting materials. Each object has a specific resonance frequency at which the object vibrates strongly and causes rupture. Applying a specific external force to this special frequency can produce large vibrations even if a small force is applied. This phenomenon is called resonance, which uses resonance technology to generate large vibrations on the cutting edge.

Product Details

Ultrasonic plastic cutting knife

Ultrasonic plastic cutting knife combined with robotic arm system

The principle of ultrasonic plastic cutting

The ultrasonic plastic cutting knife vibrates 30,000 times per second (30 kHz) with a maximum output power of 300W. Due to this motion, the ultrasonic cutting knife can easily cut resins, rubbers, non-woven fabrics, and composite materials. The cutting knife uses a 1mm thick wear-resistant hard alloy blade, and users can replace the blade themselves, extending the life of the cutter and reducing usage costs. In addition to excellent maintainability, our products are environmentally friendly because they essentially do not produce any debris, wastewater, noise, or smoke.

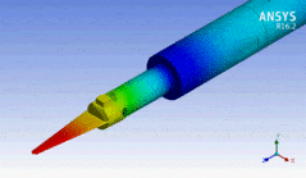

An ultrasonic plastic cutting knife consists of an 'ultrasonic transducer' that generates vibrations and an 'ultrasonic generator' that drives the transducer. Piezoelectric elements (piezoceramics) are contained within the transducer. The ultrasonic generator applies an AC voltage consistent with the transducer's frequency to the piezoelectric elements, causing the entire vibrator, including the blade, to resonate. The ultrasonic transducer is equipped with a feedback control system that conveys information about frequency or amplitude deviations caused by cutting load to the ultrasonic generator. This feedback control system maintains the resonant state and amplitude stability of the blade tip, ensuring that the tool can always cut materials quickly and cleanly.

The ultrasonic plastic cutting knife uses replaceable blade heads with a thickness of 1mm, made from alloy steel. The sharp blade reduces the contact surface area during cutting, minimizing heat generation from the blade head. The sharp blade, combined with ultrasonic waves, achieves an ideal cutting effect. This ultrasonic plastic cutting knife can be used for handheld cutting and automated mechanical clamping. For different application environments, HCSONIC offers ultrasonic cutting knives at frequencies of 20kHz, 30kHz, 35kHz, and 40kHz.

The application of ultrasonic cutting

Ultrasonic cutting knives have been widely used in the textile and food industries in recent years. Ultrasonic cutting systems can precisely cut textiles, rubber, thermoplastic films, knitted and non-knitted materials, as well as various types of food. These systems range from handheld devices to those integrated into automated machines. The advantages of ultrasonic vibration knives include: precise cutting, pressure-free cutting (which prevents deformation of soft materials such as cakes), simultaneous welding and cutting of specific material edges, fast cutting speed, and significantly reduced cleaning costs.

Factors affecting plastic cutting

--amplitude

The term 'amplitude' describes the microscopic displacement of the tool head's surface vibration during cutting. Amplitude is mechanically adjusted by the ultrasonic horn and digitally regulated by the ultrasonic generator. The size of the amplitude affects the cutting process and must be adjusted to meet the needs of each application.

--cutting speed

The speed at which the ultrasonic plastic cutting knife enters and advances through the material being cut is also a process variable that should be adjusted for each cutting process. Sometimes it is necessary to slowly penetrate the product's outer shell to avoid deformation, and then increase the speed of the cutter within the product to achieve optimal cutting results.

The advantages of ultrasonic plastic cutting

--Cutting without pressure to prevent deformation of the cut item.

--No heat generated in the product - mold remains at low temperature.

--High cutting quality, layers will not mix or break.

--Compared to mechanical cutters, it significantly reduces the 'ploughing' effect on the material.

--Simultaneously cutting nonwoven fabrics and textiles while sealing the edges to prevent fraying.

--The robust one-piece tool head blade structure almost eliminates chipping and energy loss.

--A large quantity of standard carbide cutting blades suitable for various shapes and sizes of applications.

--Ultrasonic cutting is cleaner than traditional cutters, produces fewer fragments, and does not stick to the item being cut.

--Ultrasonic cutting saves space and minimizes air release, thereby improving cutting precision.

--The ultrasonic cutting tool head features replaceable hard alloy cutting blades, which extend the tool's lifespan.

Product specifications are as follows: