High-purity indium powder,It is widely used in the aerospace, electronic industries, medical , national defense, high-tech and other fields

- Overview

- Recommended Products

Basic Information:

Definition: Metallic indium powder is a powdery material prepared from metallic indium (In) through physical or chemical methods, typically with a purity of over 99.9% (such as 99.99%, 99.999%, etc.). It has a silvery-white metallic luster and belongs to rare and scattered metal powders.

Physical and Chemical Properties:

Melting Point: Approximately 156.6°C, with a low melting point. It is soft at room temperature and can be pressed into thin sheets.

Electrical and Thermal Conductivity: It has good electrical and thermal conductivity, second only to metals like silver, copper, and gold.

Chemical Activity: It is stable in air but easily reacts with acids, halogens, etc. It is not oxidized at room temperature but can react with oxygen at high temperatures to form indium oxide (In₂O₃).

Product Details:

The main uses of metallic indium

Metallic indium is a high-value strategic metal with unique properties and wide applications. Its main uses cover multiple high-tech fields. The following are the main application areas of metallic indium:

1. ITO target material production

Indium is mainly used to produce ITO target materials, which are key raw materials for manufacturing liquid crystal displays and flat panel screens. 70% of global indium consumption is concentrated in this field because indium ingots have excellent light permeability and conductivity, suitable for making transparent conductive electrodes.

2. Semiconductor and electronic industry

The compounds of indium (such as indium arsenide and indium germanide) occupy an important position in the semiconductor industry and are widely used in the manufacturing of optoelectronic devices, solar cells, and lasers and other high-tech products.

3. Alloy materials

Indium can form alloys with other metals (such as copper, zinc, tin, etc.) to enhance the strength and corrosion resistance of the alloys. These alloys play an important role in manufacturing bearings, wires, and electrical connectors.

4. Low-melting-point alloys

Due to its low melting point, indium is often used to prepare low-melting-point alloys. These alloys play a key role in the manufacturing of fire protection devices and temperature controllers and other products.

5. Medical field

Indium compounds play an important role in medical equipment, such as being used to manufacture wires, electrodes, and sensors. In addition, the isotope of indium can also be used in nuclear medicine for diagnosis and treatment.

6. High-temperature superconducting materials

Indium cobalt series compounds have significant applications in the field of high-temperature superconducting materials and can be used to manufacture high-performance superconducting cables and magnets, promoting the development of superconducting technology.

7. Optical materials

Indium compounds exhibit excellent optical properties and are widely used in laser devices, optical communication, and optical lenses, etc.

Summary:

Metallic indium, with its unique physical and chemical properties, plays an irreplaceable role in ITO target materials, semiconductor, alloys, medical, superconducting materials, and other fields, and is one of the important raw materials for modern high-tech industries. Major indium-producing countries' resource bottlenecks: For example, more than 90% of indium powder in South Korea is imported from China (the import volume in 2024 is approximately 300 tons), used for ITO target material production.

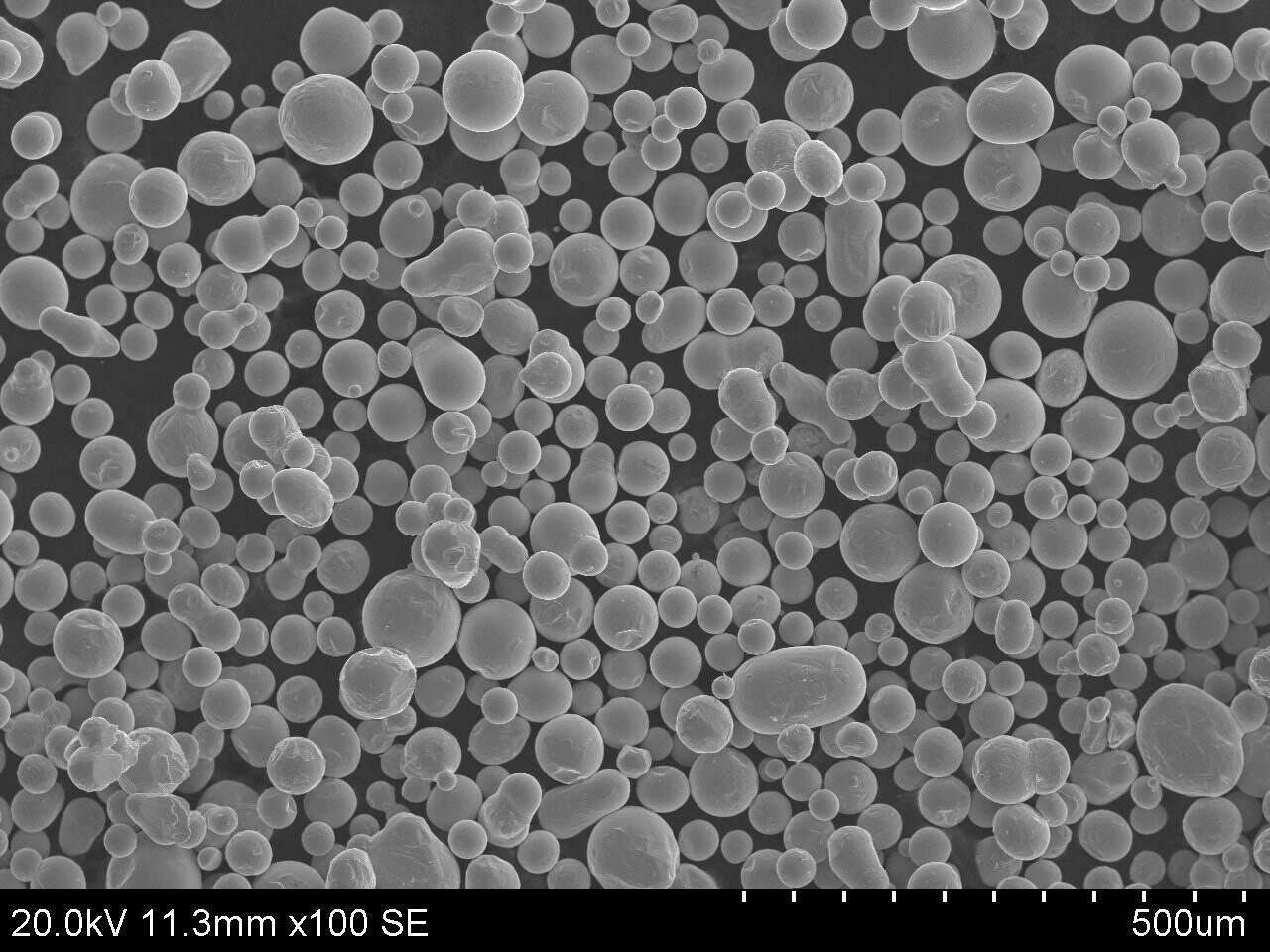

Indium powder:

【purity】:4N-5N

【Properties】: The silver-gray powder is silver-gray in color, spherical in shape, and has a particle size ranging from 20 to 50 micrometers.

【Specification】: Indium powder: 99.99% purity, 100 mesh - 800 mesh

【Packaging】: 0.5kg - 1kg per bottle, vacuum-packed in aluminum foil bags, with a plastic bottle as the outer cover.

【Usage】: It is particularly used as a sealing component in the vacuum field, and also serves as an adhesive material in acoustic sensors. At the same time, indium is widely used in the manufacturing of "fusion" materials, various alloys (such as advanced bearing alloys, low-melting-point alloys, anti-corrosion alloys, dental alloys and alloy coatings), as well as being used as thermal fuses and solder, lead-free solder paste, and electronic conductive adhesives.

The following packaging example: 200-mesh indium powder packaging (specification: 500 grams per bottle, protected by argon gas inside, and vacuum-packed)