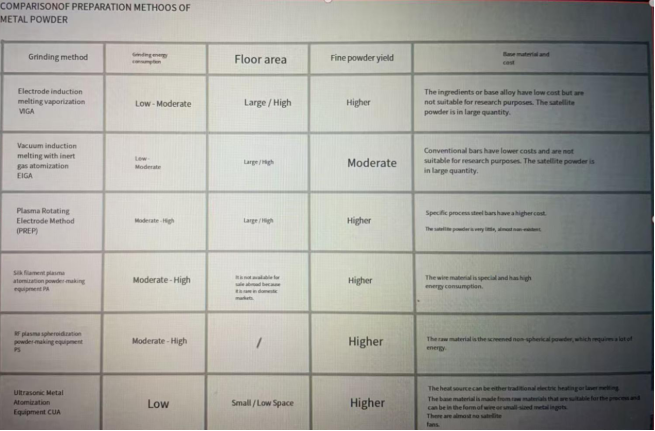

The ultrasonic metal powder manufacturing equipment is the specific application of ultrasonic atomization technology

- Overview

- Recommended Products

Product Description

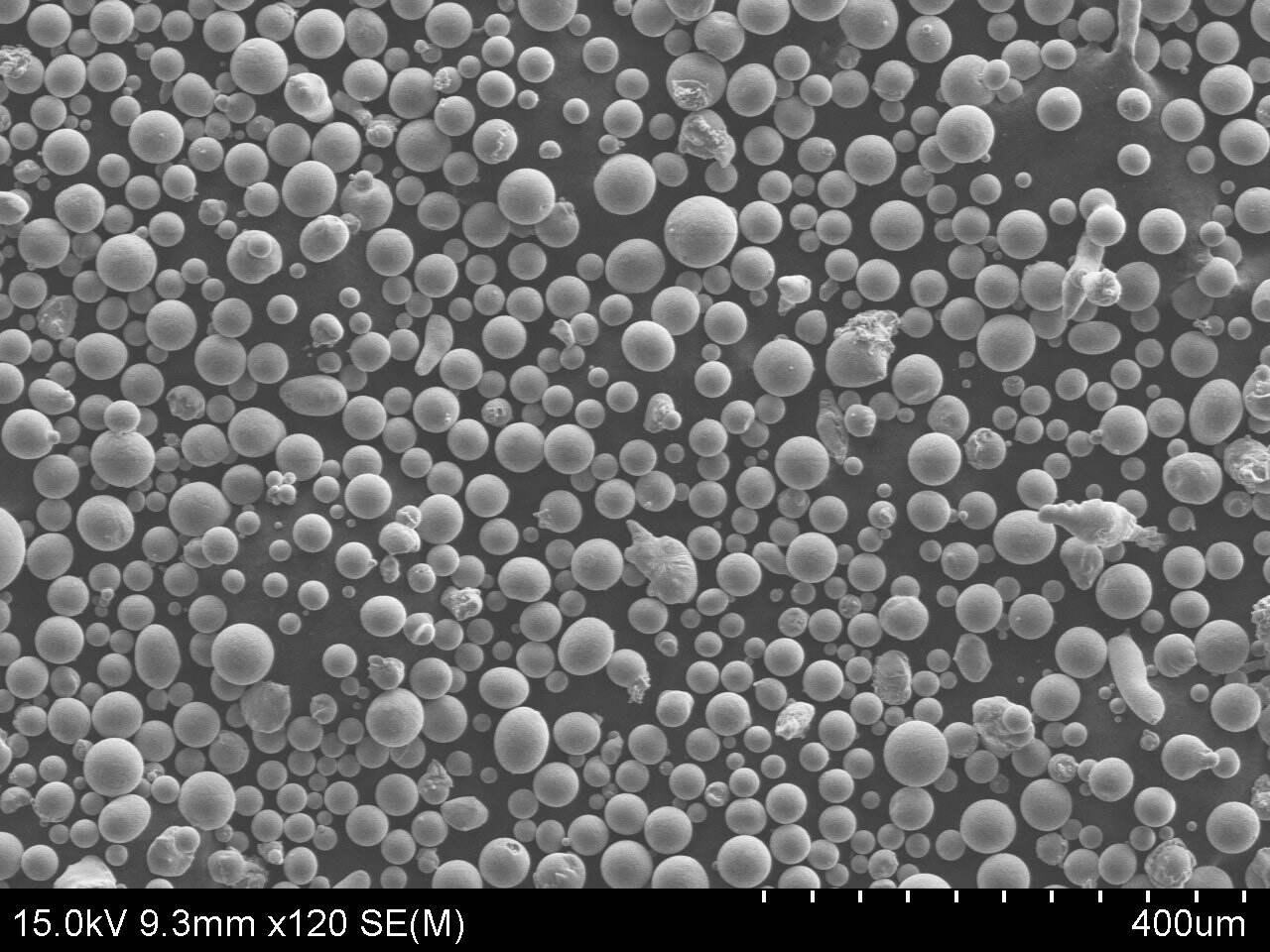

Ultrasound-assisted metal powder production is one of the applications of ultrasonic atomization technology. The powder produced by this method has good spherical shape, controllable particle size, and a narrow particle size range.

The company's independently developed high-temperature powder making equipment is a rapid multi-dimensional swing movement of the tank body, which causes the irregular movement of the mill media in the tank to produce huge impact forces; extends the motion trajectory of the mill media, improves the impact energy, and reduces impact blind spots, and the working efficiency of the high-temperature powder making equipment is dozens of times that of traditional processes. It can significantly increase the impact energy and movement of the milling medium in the tank, and enable the crushed substance particles to reach the nanoscale size. For fibers, proteins, high-hard materials and other materials that are difficult to crush in traditional ways, the crushing effect is excellent.

Metal powders include indium powder, aluminum powder, copper powder, iron powder, nickel powder, titanium powder, tungsten powder, molybdenum powder, etc. The metal powder has good anticorrosion properties, is not easy to evaporate or burn, and can be stored for a long time, which is highly environmentally friendly. Widely used in automobiles, aerospace, electronics, machinery and construction fields

Product Details

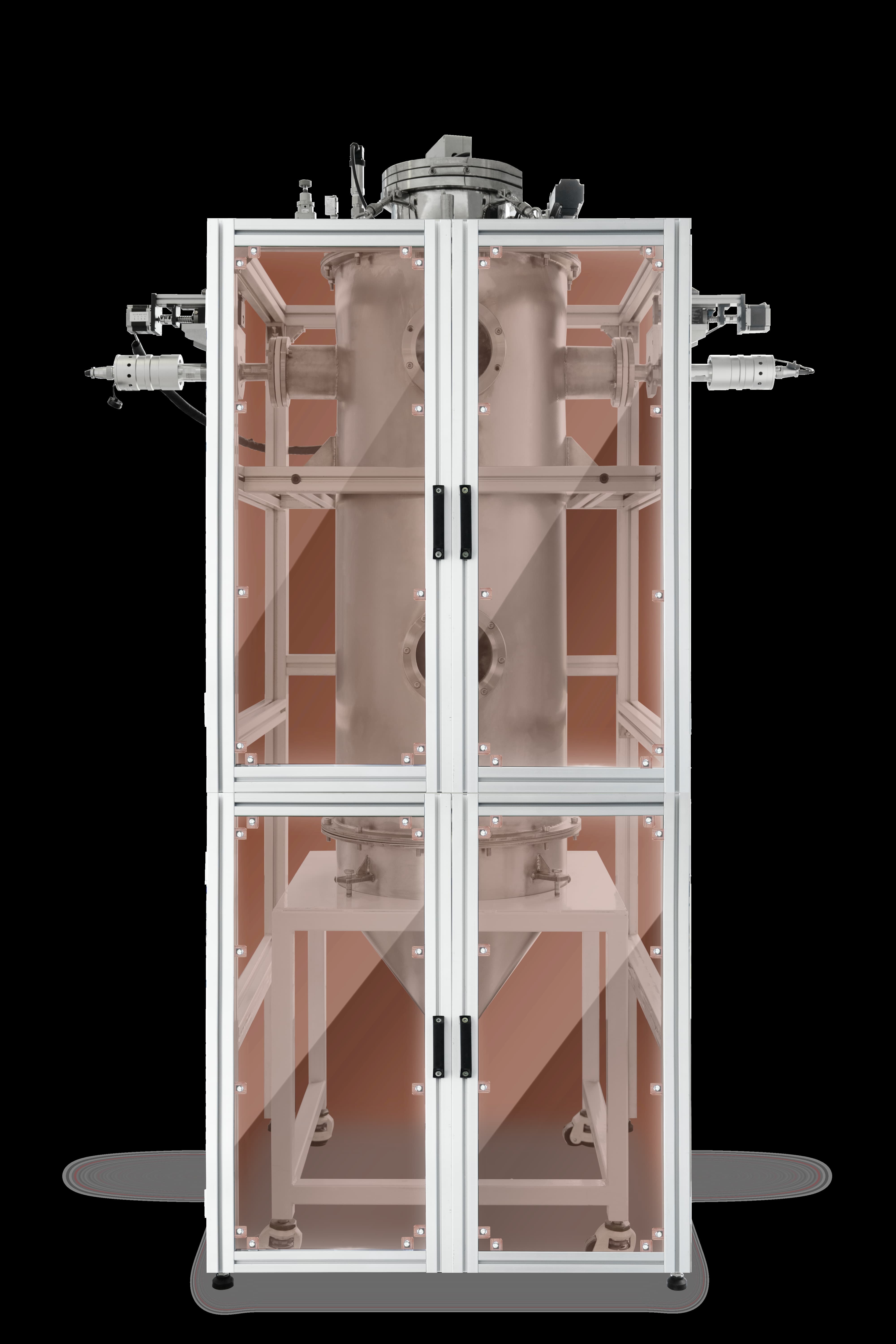

Ultrasonic metal atomizing powder process and equipment composition

Brief introduction of manufacturing process

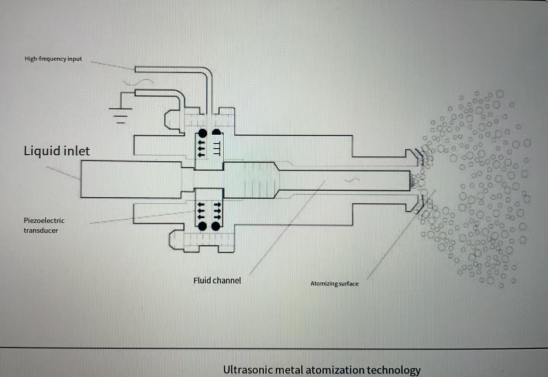

The ultrasonic metal powdering technology process involves heating the required powder material to a liquid state in the front-end melting module. This liquid is then introduced into the mid-stage ultrasonic atomization surface. Simultaneously, an ultrasonic generator produces high-frequency electromagnetic energy, which is converted into high-frequency mechanical energy via an ultrasonic transducer, resulting in longitudinal high-frequency vibration. The output end of the transducer is connected to an amplitude booster, which amplifies the vibration and transmits it to the atomization surface, generating a standing wave. As the molten metal liquid passes through the atomization surface, it is fragmented into uniform micron-sized droplets under the influence of the high-frequency vibration and standing wave. In an inert gas protection preparation environment, these droplets rapidly cool and solidify, forming micron-sized metal solid particles. These solidified metal particles fall into the powder collection cylinder and are collected to become the desired metal powder.

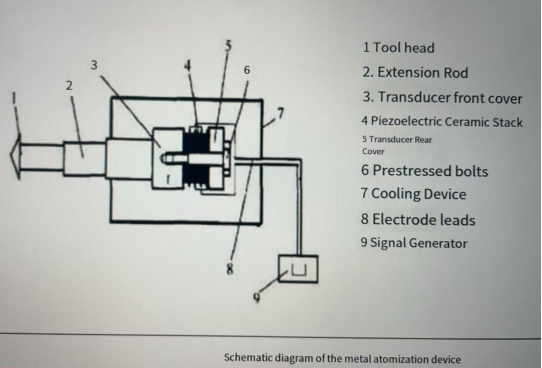

Equipment composition

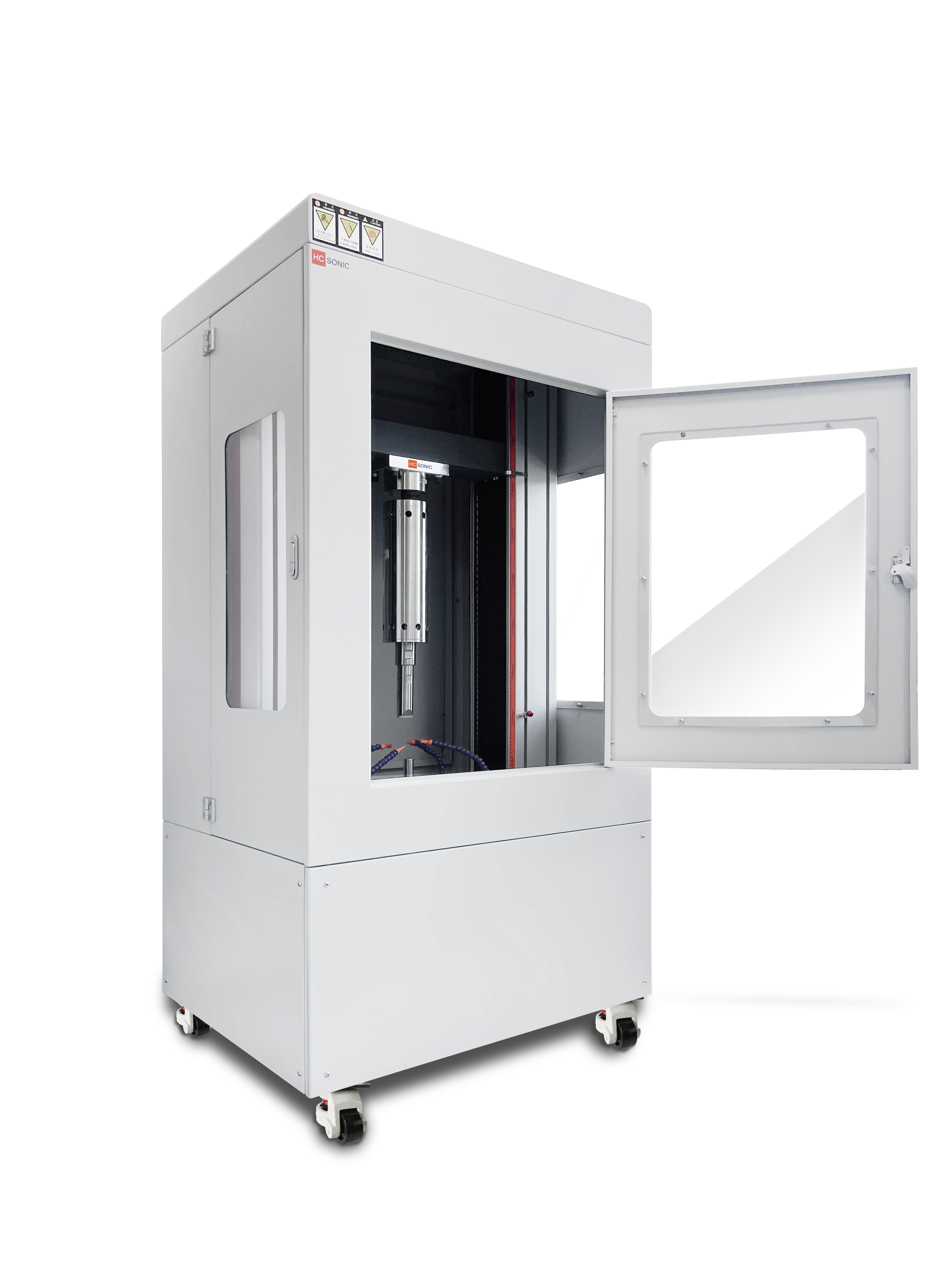

Ultrasonic generator:

The ultrasonic generator converts 220V AC power into high-frequency oscillating electrical energy to supply sufficient electrical power for the entire nebulizer device.

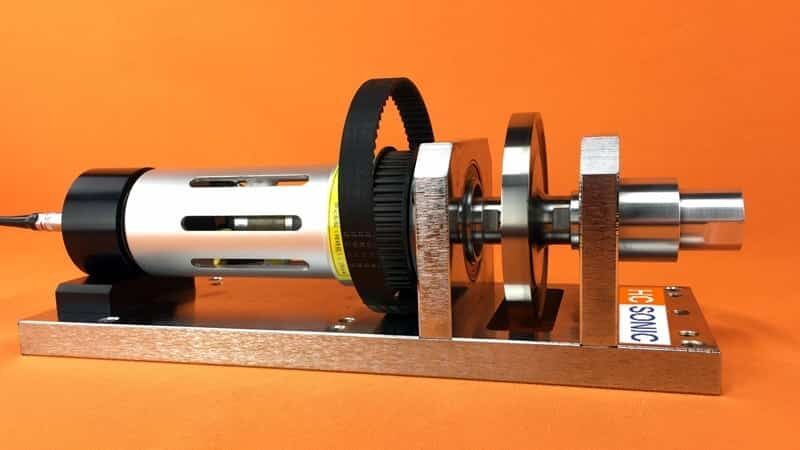

Ultrasonic transducer

More commonly used are sandwich-type piezoelectric ceramic transducers, which function to convert high-frequency electrical oscillation signals into mechanical vibrations, transforming electrical energy into high-frequency vibrations.

Variable amplitude rod

An ultrasonic amplitude modulator, also known as an ultrasonic concentrator, can amplify the particle displacement and velocity of mechanical vibrations, concentrating ultrasonic energy into a smaller area.

Ultrasonic atomization head

Ultrasonic atomization head, a component that directly contacts the material, is generally made of alloys. The melting point of the atomized metal is limited by the material of the atomization head, making this method more suitable for the preparation of metals and alloys with medium and low melting points. The transducer and horn transmit high-frequency vibrations to the atomization head, which then acts on the molten metal, atomizing it into fine particles and powder. On the other hand, surface tension theory suggests that the formation of droplets is due to the instability of surface waves in the liquid causing atomization. When ultrasonic waves of a certain intensity pass through the liquid and reach the gas-liquid interface, they form surface tension waves. Under the action of a force perpendicular to the surface tension waves, once the amplitude of the vibrating surface reaches a certain value, droplets fly off from the wave peaks to form atomization. This theory posits that surface tension waves generate droplets at their wave peaks, with droplet size being directly proportional to the wavelength.

The process of nebulization

Ultrasonic metal atomization involves using high-speed ultrasonic vibrations to impact molten metal or alloy streams, ultimately producing fine metal powder through a process of atomization. In metal ultrasonic atomization, an oscillator converts AC electricity into high-frequency electromagnetic energy, which is then transformed into high-frequency vibration by an ultrasonic transducer. This vibration is amplified via a horn and finally transmitted to the tool head (atomizer). When the ultrasonic atomizer acts on the molten metal, the melt spreads into a thin film under high-frequency vibration. At a certain amplitude of ultrasonic vibration, the molten metal is shattered into droplets, which fly off the vibrating surface to form mist droplets.

The process of ultrasonic metal powder production is generally divided into two stages: fragmentation and condensation. The first stage involves fragmenting heated molten metal or alloy. This step results in the production of metal droplets and affects the final size of the metal powder. The second stage of condensation determines the formation of the final metal particles, directly impacting the shape of the metal powder, primarily involving issues of heat conduction.

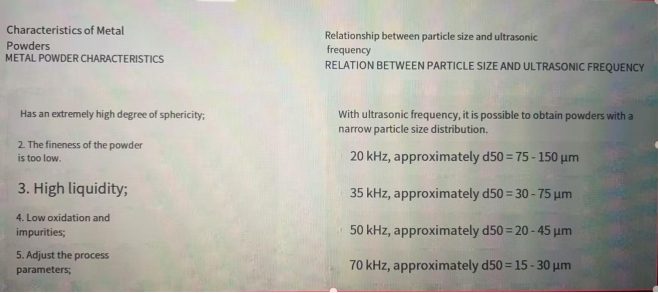

Characteristics of Metal Powders:

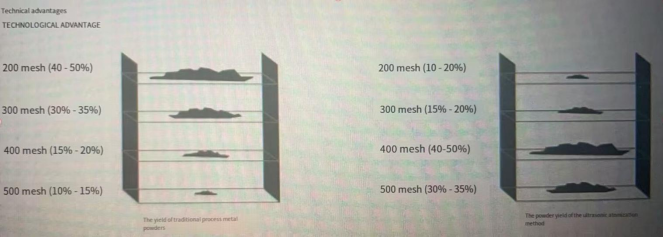

Advantages of ultrasonic powder production: