Ultrasonic seamless suture system does not require needle and thread, high suture strength, good sealing, and fast suture speed

- Overview

- Recommended Products

- High stability: During ultrasonic seam-free welding, the rotation of the welding wheel and the pressure wheel is perfectly synchronized, with no speed or angle differences, which prevents fabric stretching, twisting, or deformation, achieving extremely high precision. Due to the use of thermal fusion effects, there is no need for needles and threads, resulting in increased water resistance, lighter weight, and easier folding of the product.

- Seam and cut synchronization: Ultrasonic seam-free welding equipment is suitable not only for continuous sewing but also for cutting textiles simultaneously while welding, and can achieve automatic edge sealing.

- No heat radiation: During ultrasonic welding, energy penetrates through material layers for welding without heat radiation. In continuous sewing processes, heat does not transfer to the product, which is particularly advantageous for packaging heat-sensitive products.

- Controlled weld seams: The fabric, under the traction of the welding wheel and the pressure wheel, passes through them, and ultrasonic waves are used to weld the fabric. By changing the pressure wheel, the size of the weld seam and the embossing can be altered, making it more flexible and convenient to use.

- Wide range of applications: All thermoplastic (softens when heated) fabrics, special tapes, films can be welded using ultrasonic seam-free welding equipment. The rollers are made of quenched steel, extending their service life.

- Technical industry: filter bags, health products, medical mattresses and pillows, needle-punched blankets, surgical sheets, foil, bulletproof vests, blinds and sunshades, pleated filters, shower curtains, spacer fabrics, seat covers, MBR modules, etc.

- Clothing industry: outdoor clothing, protective suits, bras, underwear, medical clothing and curtains, soft shells, sportswear, cleanroom clothing, etc.

- Automotive industry: interior and insulation projects, protective car covers, sunshades, etc.

Product Description

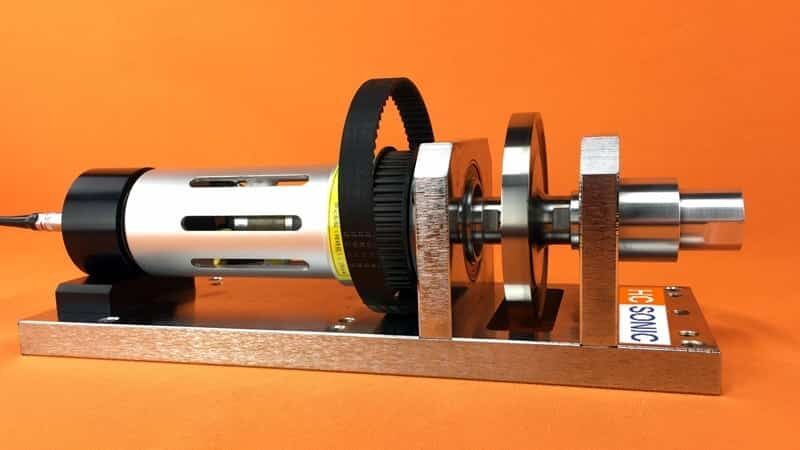

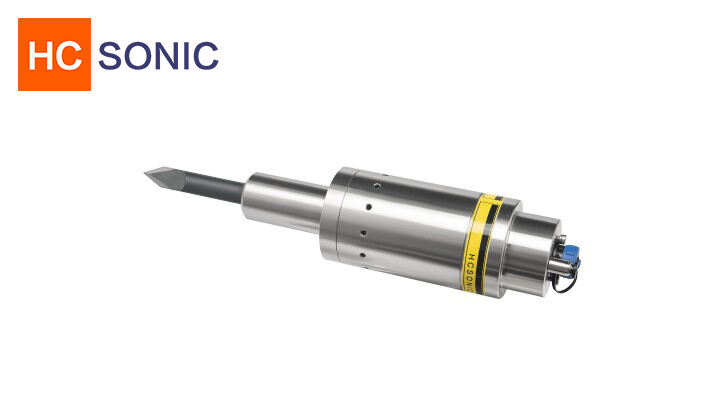

The ultrasonic seamless suture system consists of a 35k ultrasonic transducer, amplitude rod (fixed action), a disc-type welding head and a matching special CNC power supply combination. Ultrasonic CNC power supply converts the mains power into 35k high-frequency high-voltage AC power and supplies ultrasonic transducers. The ultrasonic transducer converts electrical energy into mechanical energy (ultrasonic waves). The transducer generates amplitude when performing telescopic motion in longitudinal direction, and then passes it to the disc-type welding head through the amplitude variable rod. This makes the disc-type welding head welded, equipped with a frame, pressing wheel, auxiliary structure and control components, which is a complete ultrasonic cutting sewing machine.

Traditional sewing machines sew two pieces of cloth together by needle-driven thread. During the threading process, not only is the fabric punctured, but there is no bond between the cloth, but they are tied together by a thin thread. This way the cloth is easily pulled and the thread is easily broken. Thermoplastic fabric can be sewn together by hot air welding, and needlework does not require needlework, but the welding temperature is not easy to control and the welding speed is slow. Ultrasonic seamless suture system can sew most thermoplastic fabrics. Compared with ordinary needle and thread suture, ultrasonic suture does not require needle and thread, high suture strength, good sealing, and fast suture speed. In addition, the ultrasonic seamless sewing system completely solves the problem that the movement direction of the ultrasonic welding head is inconsistent with the movement direction of the fabric and is not synchronized, which will replace ordinary sewing machines to a large extent.

Product Details

Seamless sewing equipment features

The core technology of the ultrasonic seam-free sewing system lies in the use of a disc-shaped welding head for rolling welding, ingeniously converting the longitudinal vibration of the transducer into radial vibration radiating outward at 360 degrees along the diameter of the disc-shaped welding head. Unlike traditional lace machines, which typically consist of a flat tool head and a patterned roller, and where the tool head remains stationary, leading to easy deformation and wrinkling of fabrics during operation, the rolling welding type seamless sewing equipment uses two discs to vibrate and sew the fabric, effectively solving this issue. This significantly reduces the volume of the vibration system itself and greatly decreases the installation dimensions, making the entire machine aesthetically pleasing, smaller in size, and much lighter in weight.

The advantages of seamless suturing

scope of application

product specifications:

usage frequency |

20~36 Khz |

power range |

800W |

sewing speed |

0.1-1.3m/s |

roller amplitude |

18~28μm |

Roller temperature |

>60℃ |

Roller material |

titanium, quenched steel |

work mode |

Continuous\intermittent |

Product nature |

sewing machine parts |

weld seam width |

0.1~25mm |

product model |

HC-WS3508GL |