Ultrasonic rubber cutting knife can easily cut resins, rubber various overlapping composite materials etc

- Overview

- Recommended Products

Product Description

The principle of an ultrasonic rubber cutting knife is to convert 50/60Hz current into 20, 30 or 40kHz electrical energy through an ultrasonic generator (also known as an ultrasonic power supply). The converted high-frequency electrical energy is converted again through the transducer to mechanical vibration of the same frequency, which is then transferred to the cutting knife through an amplitude modulator device that can change the amplitude. The ultrasonic rubber cutting knife vibrates at an amplitude of 10-70μm along its length, repeating 40,000 times (40 kHz) per second (the vibration of its blade is microscopic, which is generally difficult to see with the naked eye). The cutting knife then transfers the received vibration energy to the cutting surface of the workpiece to be cut. In this area, the vibration energy is cut by activating the rubber molecular energy and opening the molecular chain.

Ultrasonic cutting is a cutting using the energy of sound waves. It does not require sharp edges or large pressure, and will not cause the edge collapse or damage of the cut material. Ultrasonic rubber cutting knife can easily cut resins, rubber, plastics, fabrics and various overlapping composite materials etc.

Product Details

Ultrasonic rubber cutting knife

Issues in rubber cutting

Traditional rubber cutting techniques require lubrication of the rubber during cutting, and they suffer from slow cutting speeds, large cut surfaces producing significant dust and debris, uneven cut edges, and sticking to the blade. Many companies still use traditional manual methods for cutting, which not only fail to meet productivity needs but also pose safety hazards to workers.

For rubber products, cold cutting is more suitable compared to hot cutting. Cold cutting has advantages such as minimal heat generation, minimal thermal deformation, reduced dust production during the cutting process, and the cut surface does not age or crack due to high temperatures. Ultrasonic rubber cutting technology falls under cold cutting, utilizing ultrasonic energy to locally heat and melt the rubber being cut, thereby achieving the purpose of material separation.

The principle of traditional cutting

Traditional cutting uses sharp-edged tools to concentrate very high pressure at the edge, pressing it against the material being cut. When the pressure exceeds the shear strength of the material, the molecular bonds are pulled apart, achieving the cut. Because the material is forcibly pulled apart by strong pressure, the tool's edge must be extremely sharp, and the material itself must withstand significant pressure. Therefore, it is not effective for soft, elastic materials, and even more challenging for sticky materials.

Traditional cutting

The principle of ultrasonic rubber cutting

Ultrasonic cutting utilizes the energy of sound waves for cutting, eliminating the need for sharp blades or significant pressure, and preventing chipping or damage to the material being cut. Ultrasonic rubber cutting knives can easily cut resins, rubber, plastics, fabrics, and various overlapping composite materials and foods.

The principle of ultrasonic rubber cutting knives involves converting 50/60Hz current into 20, 30, or 40kHz electrical energy using an ultrasonic generator (also known as an ultrasonic power supply). The high-frequency electrical energy is then converted back into mechanical vibrations of the same frequency through a transducer. These mechanical vibrations are transmitted to the cutting blade via an amplitude modulator that can adjust the amplitude. The cutting blade vibrates along its length at an amplitude of 10-70μm, repeating 40,000 times per second (40 kHz) (the vibration of the blade is microscopic and generally difficult to see with the naked eye). The cutting blade transfers the received vibrational energy to the cutting surface of the workpiece, where the energy cuts the material by activating rubber molecules and breaking molecular chains.

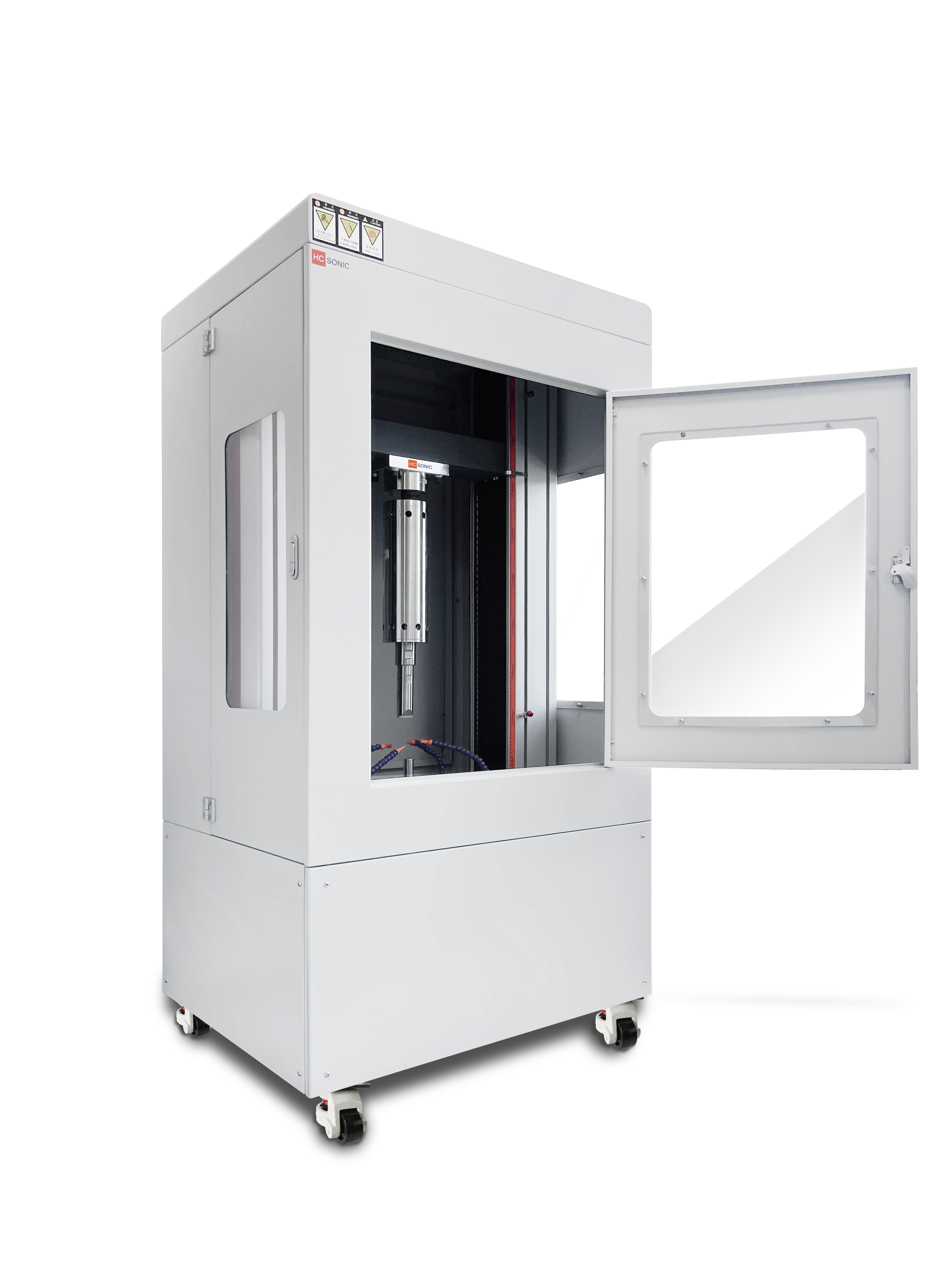

Handheld ultrasonic rubber cutting knife

The composition of the ultrasonic rubber cutting tool

--Ultrasonic generator (power supply)

The ultrasonic generator converts the power current of 110VAC or 220VAC into a high-frequency high-voltage electrical signal.

--Ultrasonic transducer

Ultrasonic transducers utilize high-frequency electrical signals from ultrasonic generators and convert them into linear mechanical motion. This conversion is achieved using piezoelectric ceramic disks, which expand when voltage is applied. Transducers used for ultrasonic rubber cutting are specially designed to allow air intake and exhaust for cooling purposes.

--Ultrasonic booster (horn)

The ultrasonic horn is an adjustable component that mechanically regulates the displacement of the transducer's linear vibration to the required level for specific applications, thereby achieving optimal cutting performance. The ultrasonic horn also provides a safe, non-vibrating position where it can be mounted on the cutting tool.

--Ultrasonic cutting tool head (blade)

Ultrasonic cutting blades are custom tools designed to vibrate at specific frequencies. These tools are meticulously designed using computer modeling techniques to achieve optimal performance and longevity. The ultrasonic blade must be tuned to match the system's frequency. This tuning process requires consideration of the blade head's mass, length, and geometry. HCSONIC offers various configurations, each tailored for specific applications, ensuring excellent long-term usage performance.

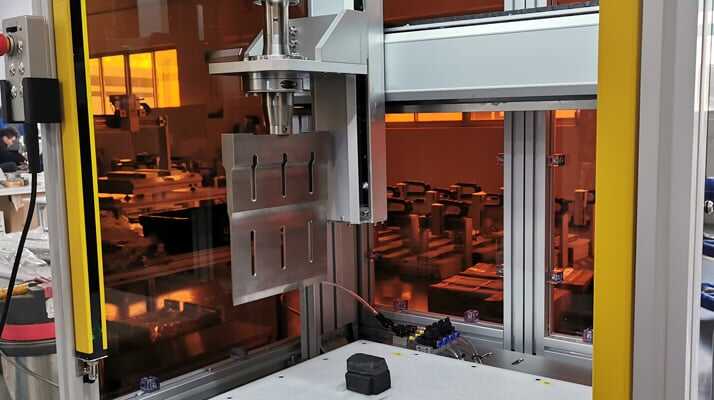

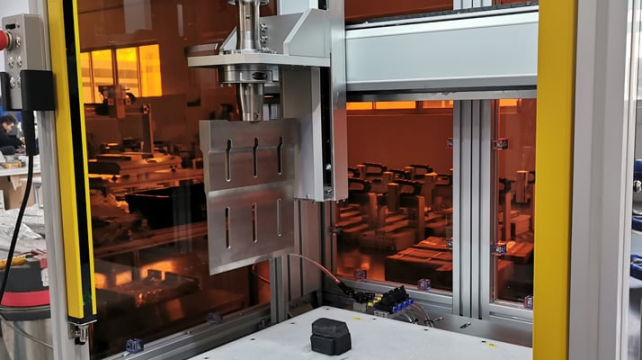

Automated rubber cutting system (optional)

Proper positioning and movement of rubber and ultrasonic blades can be achieved using automated machines. Automation is crucial for achieving the correct cutting position, direction, and speed. Typically, these processing systems utilize servo-driven mechanisms to precisely control the speed and position of the rubber and cutting tools.

Factors affecting ultrasonic rubber cutting

--equipment startup time

Due to the need for a narrow blade design, the design and manufacture of ultrasonic cutting tool heads are challenging. Vibration of the blade at maximum amplitude without load sometimes leads to premature damage of the blade. Therefore, the signal from the ultrasonic generator should be synchronized with the automated machine so that the blade reaches full vibration before it comes into contact with the rubber. Vibration before contact is necessary to avoid deformation of the rubber, which would occur due to contact with a non-vibrating cutting surface.

--vibration amplitude

The term 'amplitude' describes the microscopic displacement of the tool head's surface vibration during cutting. Amplitude is mechanically adjusted by the ultrasonic horn and digitally regulated by the ultrasonic generator. The size of the amplitude affects the cutting process and must be adjusted to meet the needs of each application.

--cutting speed

The speed at which the ultrasonic cutting blade enters and advances through the material being cut is also a process variable that should be adjusted for each cutting process. Sometimes it is necessary to slowly penetrate the product's outer shell to avoid deformation, and then increase the speed of the cutter within the product to achieve optimal cutting results.

--Vibration end time

Depending on the consistency of the material being cut, the completed slice may tend to adhere to the side of the cutting blade after the ultrasonic vibration is turned off. Therefore, maintaining ultrasonic vibration when removing the tool head from the product can utilize the frictionless characteristic to release the cutting blade cleaner and more consistently.

Advantages of ultrasonic rubber cutting

--Extremely high cutting precision: smooth, clear, and clean cuts.

--Repeated cutting: The blade output is monitored by a closed-loop circuit to ensure consistent cutting performance.

--Lower temperatures: rubber has almost no heat.

--Dry: The ultrasonic rubber cutting blade operates without lubrication, vibrating 20,000 to 40,000 times per second (depending on the application). Therefore, the blade can smoothly pass through the rubber.

--Low energy consumption: The blade only vibrates when cutting, requiring about 100 watts or less power for typical thin material applications.

--Easy to integrate into automation: The ultrasonic rubber cutting process is very simple and can be upgraded into existing mechanical structures or installed on new equipment.

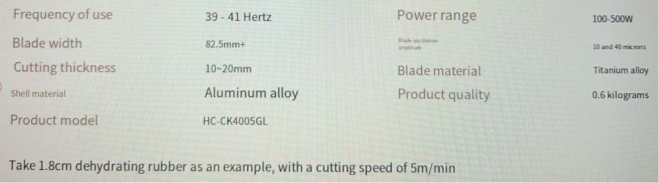

Product specifications are as follows: