Use Ultrasonic cavitation metal surface treatment system to evaluate the relative resistance of materials

- Overview

- Recommended Products

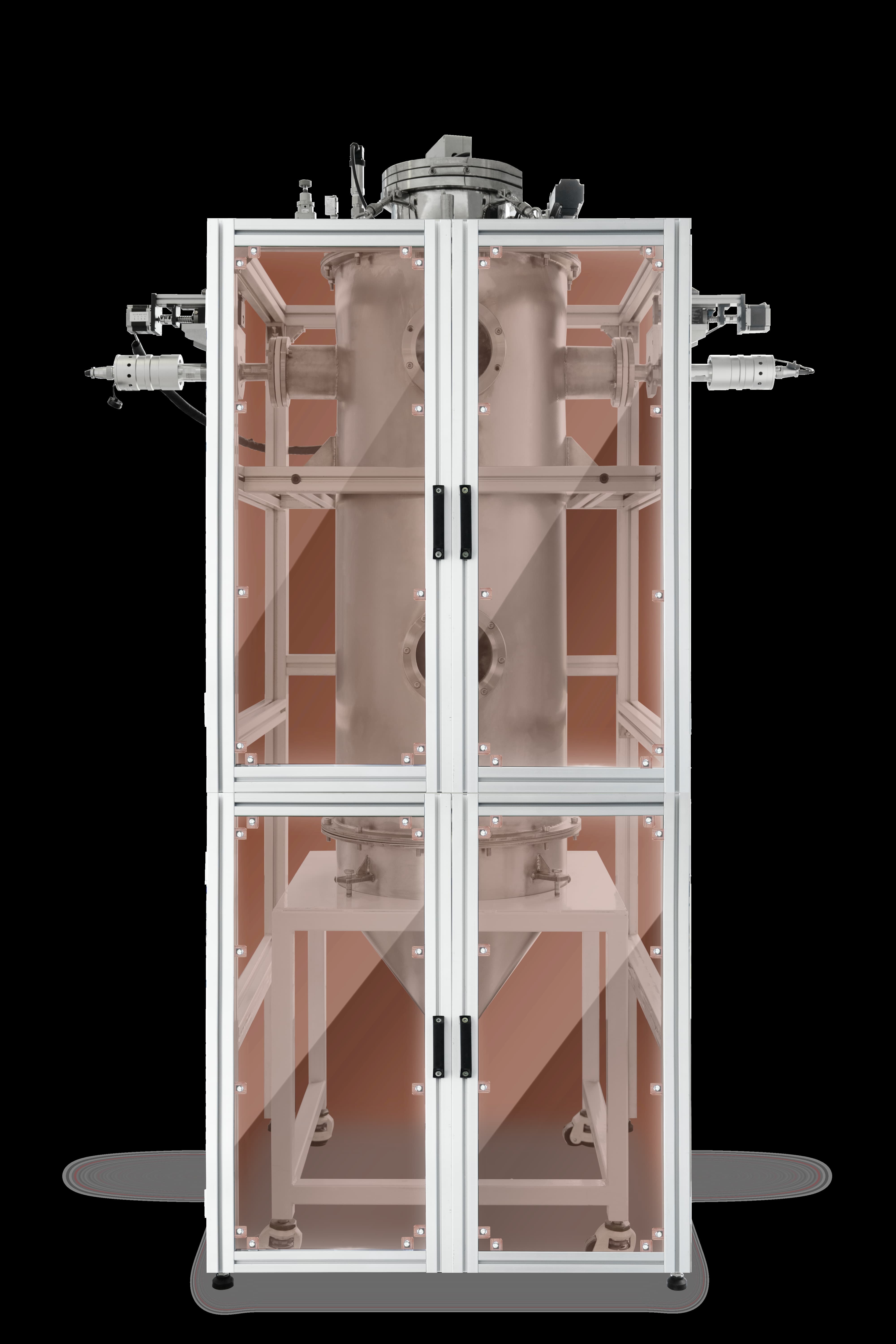

Product Description

Ultrasonic cavitation system uses high-power ultrasonic to act on the sample, causing cavitation damage to the surface of the sample immersed in the liquid at high frequency. The vibration of the sample in the liquid will lead to the generation and rupture of bubbles. The rupture of this bubble will damage and erode the sample surface (material loss), simulating the cavitation phenomenon between the contact surface of the sample and the liquid, and then analyze the cavitation resistance of the material and compare the cavitation resistance of various materials.

Ultrasonic cavitation system Use ultrasonic cavitation systems to evaluate the relative resistance of materials: such as water pumps, water turbines, hydraulic dynamometers, valves, bearings, diesel engine cylinder liners, ship propellers, hydrofoils and blocked internal pipelines. This test method can also be used to screen materials that can withstand sudden liquid impact erosion, such as low-pressure steam turbines and aircraft, missiles and spacecraft that may fly in heavy rain.

Product Details

Ultrasonic cavitation test system

cavitation phenomenon

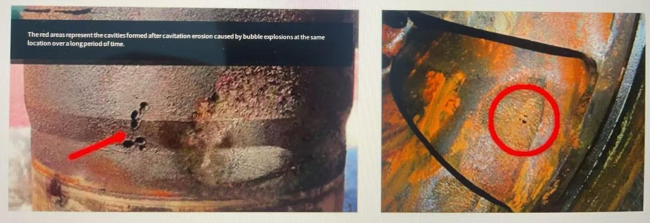

Cavitation, also known as cavitation erosion, refers to the phenomenon of cavity-like corrosion damage occurring on metal surfaces in contact with fluids under conditions of high-speed flow and pressure changes. It commonly occurs in areas such as the tips of centrifugal pump blades where there is a high-speed pressure reduction zone, forming cavities that burst when they enter high-pressure zones, creating impact pressures that destroy the protective film on the metal surface, thereby accelerating corrosion.

When materials are exposed to cavitation fluids, cavitation occurs. The rupture of cavitation bubbles generates strong shock waves and microjets, leading to highly localized surface stresses. The repetitive loading caused by repeated bubble ruptures can result in local surface fatigue failure and subsequent material detachment or spalling. In the study of wear-resistant materials, it is necessary to measure, compare, and evaluate the wear resistance properties of materials. For example, components such as pumps, valves, turbine runners, and blades often fail due to cavitation damage.

Centrifugal pump cavitation phenomenon

Cavitation damage is one of the common failure modes in the fuel supply system components of aircraft engines. Aircraft engine fuel supply system components operate in high-pressure aviation kerosene media. The presence of numerous afterburners and pump components results in significant pressure variations between different parts of the system during operation, making cavitation damage highly likely. This can even lead to component perforation and fracture, severely affecting the safe operation of aircraft engines.

Principle of Ultrasonic Cavitation System

The ultrasonic cavitation system works by applying high-power ultrasound to the sample, causing the surface of the sample immersed in liquid to vibrate at high frequencies and produce cavitation damage. The vibration of the sample in the liquid leads to the formation and rupture of bubbles, and the collapse of these bubbles causes erosion and material loss on the sample's surface. This simulates the cavitation phenomenon at the interface between the sample and the liquid, allowing for the analysis of the sample's resistance to cavitation and the comparison of the cavitation resistance of various materials.

Ultrasonic cavitation system applications

Ultrasonic cavitation systems are used to evaluate the relative resistance capabilities of materials: for example, water pumps, turbines, hydraulic force gauges, valves, bearings, diesel engine cylinder liners, ship propellers, hydrofoils, and internal pipelines that may become blocked. This test method can also be used to screen materials that can withstand sudden liquid impact erosion, such as low-pressure steam turbines and aircraft, missiles, and spacecraft that may operate in heavy rain.

Advantages of the ultrasonic cavitation system

Ultrasonic cavitation systems have advantages such as high power, low investment, easy installation, and stable experimental results.