- Overview

- Recommended Products

Product Description

Ultrasonic fabric cutters are designed to provide the best edge seal on all fabrics without adjusting the machine for different fabrics or thicknesses. Therefore, production efficiency is improved, downtime is reduced, and the cutting method of various fabrics is changed. Ultrasonic fabric cutters are strongly heated and quickly concentrate on the cutting head for cutting, all fabrics have excellent edge seals and most importantly to prevent wear.

Product Details

Ultrasonic fabric cutting

Different fabric cutting techniques

Fabric cutting processes are generally divided into cold cutting and hot cutting. Both of these cutting methods have certain limitations. Compared to cold cutting, when using ultrasonic fabric cutting, the edges of thermoplastic materials melt together after being cut. Compared to hot cutting, ultrasonic cutting makes the edges of the cut fabric very soft, avoiding the melting shrinkage that causes overly thickened edges. Since ultrasonic waves heat the fabric from the inside, there is also no risk of the fabric turning yellow.

Ultrasonic fabric cutting utilizes ultrasonic energy to locally heat and melt the material being cut, achieving the cutting purpose without the need for a sharp blade. It is commonly used for cutting difficult-to-cut materials such as thermoplastic resin boards, sheets, films, laminates, carbon fiber composites, fabrics, and rubber.

The ultrasonic fabric cutting knife vibrates 40,000 times per second (40 kHz) with a maximum output power of 100W, making it easy to cut resins, rubbers, non-woven fabrics, and composite materials due to this motion. The housing of the fabric cutting knife is made of stainless steel, while the blade is crafted from inert, hard, wear-resistant metal—high-speed steel—with a thickness of 0.6mm, which does not undergo persistent chemical reactions with the cutting material. Users can replace the blades themselves, and the high-frequency vibration reduces friction resistance on the cutting surface, extending the blade's lifespan and saving costs.

The composition of the ultrasonic fabric cutting knife

--Ultrasonic generator (power source)

The ultrasonic generator converts the power current of 110VAC or 220VAC into a high-frequency high-voltage electrical signal.

--Ultrasonic transducer

Ultrasonic transducers utilize high-frequency electrical signals from ultrasonic generators and convert them into linear mechanical motion. This conversion is achieved using piezoelectric ceramic disks, which expand when voltage is applied.

--Ultrasonic booster (amplifier)

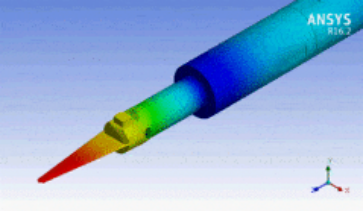

The ultrasonic horn is an adjustable component that mechanically regulates the displacement of the transducer's linear vibration to the required level for specific applications, thereby achieving optimal cutting performance. Ultrasonic fabric cutting equipment integrates the transducer and horn into one unit, resulting in less heat generation, higher efficiency, and greater stability.

--Ultrasonic cutting tool head (blade)

Ultrasonic cutting blades are custom tools designed to vibrate at specific frequencies. These tools are meticulously designed using computer modeling techniques to achieve optimal performance and longevity. The ultrasonic blade must be tuned to match the system's frequency. This tuning process requires consideration of the blade head's mass, length, and geometry.

The ultrasonic fabric cutting knife has replaceable blades.

The advantages of ultrasonic fabric cutting:

--The edges are soft.

The cutting edges of the fabric are very soft, avoiding the melting shrinkage that causes excessive thickening at the edges, which affects aesthetics.

--Fabric does not yellow.

Since ultrasound heats the fabric through internal friction, there will be no yellowing of the fabric due to excessively high surface temperatures.

---will not fray or wear out

Simultaneously cutting and sealing the fabric edges results in very neat edges, ensuring that neither the warp nor weft threads of the fabric shift, preventing fraying and damage.

--No sharp blade tip

The blade vibrates and rubs tens of thousands of times per second, locally heating the fabric to melt it, so there is no need for an especially sharp blade.

--pollution-free

The maximum temperature of the ultrasonic knife head during cutting does not exceed 50°C, so it does not produce smoke or odor, making its use safer.

--Use it simply

Ultrasonic fabric cutting knives can be used handheld, or installed into existing production lines, or added to robotic arms.

--The application range is wide.

Various textile materials and plastic films can be cut using ultrasonic technology, such as natural fibers, synthetic fibers, nonwoven fabrics, and knitted fabrics.

Products not recommended for cutting

--Products with high fat and semi-liquid content

--products that are easy to cut

--irregularly shaped products

--A product with many solid particles

--non-thermally fusible products

Current status of ultrasonic cutting applications

Ultrasonic cutting knives have been widely used in the textile and food industries in recent years. Ultrasonic cutting equipment can precisely cut textiles, rubber, thermoplastic films, knitted and non-knitted materials, as well as various foods. These devices range from handheld units to systems integrated into automated machines. The advantages of ultrasonic cutting technology include: precise cutting, pressure-free cutting (which prevents deformation of soft materials such as cakes), simultaneous welding and cutting of specific material edges, fast cutting speed, and significantly reduced cleaning costs.

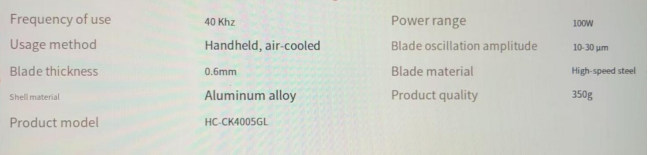

Product specifications are as follows: