Ultrasonic food cutting , low friction cutting surface can cleanly slice many food products without debris

- Overview

- Recommended Products

Product Description

Ultrasonic food cutting is a process that uses tools to vibrate at high frequency. Applying ultrasonic vibrations to the tool creates a nearly frictionless cutting surface, which will bring many benefits to cutting. This low friction cutting surface can cleanly slice many food products without debris. Foods that contain items such as vegetables, meat, nuts, berries and fruits can be cut, and the internal products will not deform or displace. Low friction conditions also reduce the tendency for products such as nougat and other fudges to stick to the cutter, resulting in a more even cut. Because ultrasonic generators have advanced process control functions, the performance of ultrasonic food cutting knives can be easily controlled by simply adjusting equipment parameters.

Product Details

Ultrasonic food cutting

Introduction to Ultrasonic Food Cutting

Compared to traditional cutting methods, the HCSONIC ultrasonic food cutter offers several advantages: it provides cleaner cuts, easier equipment cleaning, shorter downtime, better cost-effectiveness, higher consistency on cut surfaces, and longer blade life.

The ultrasonic food cutting head is manufactured using precise wire cutting processes that reduce stress and extend lifespan. HCSONIC can fully customize OEM components, kits, and heads. Typical applications include cheese cutting; cake and dessert cutting; candy cutting; meat cutting; sandwich and packaging cutting.

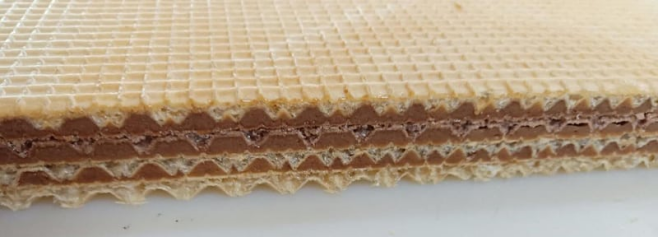

Ultrasonic food cutting is a process that utilizes a blade vibrating at high frequencies. Applying ultrasonic vibrations to the blade creates an almost frictionless cutting surface, which brings numerous benefits to the cutting process. This low-friction cutting surface can cleanly slice many foods into thin pieces without producing crumbs.

It can cut foods containing items such as vegetables, meat, nuts, berries, and fruits, without deforming or displacing the internal products. The low-friction conditions also reduce the tendency of products like nougat and other gummies to stick to the blade, resulting in more uniform cuts. Due to the advanced process control features of the ultrasonic generator, the performance of the ultrasonic food cutter can be easily controlled by simply adjusting the equipment parameters.

The ultrasonic food cutter includes the following components.

--Ultrasonic generator (power supply)

The ultrasonic generator converts the power current of 110VAC or 220VAC into a high-frequency high-voltage electrical signal.

--Ultrasonic transducer

Ultrasonic transducers utilize high-frequency electrical signals from ultrasonic generators and convert them into linear mechanical motion.

This conversion is achieved using piezoceramic disks that expand when voltage is applied. The ultrasonic transducer used in the food cutting system is specially designed to introduce and expel air for cooling purposes.

--Ultrasonic booster (amplifier)

The ultrasonic horn is an adjustable component that mechanically regulates the displacement of the transducer's linear vibration to the required level for specific applications, producing optimal cutting performance. The ultrasonic horn also provides a safe, non-vibrating location where it can be mounted on the cutting tool.

In food-cutting systems, the horns are made from one-piece titanium alloy designs to achieve maximum cutting precision and repeatability. Additionally, the one-piece design allows thorough rinsing, unlike multi-piece ultrasonic horns that can harbor bacteria.

--Ultrasonic cutting tool head (blade)

Ultrasonic cutting blades are custom tools designed to vibrate at specific frequencies. These tools are meticulously designed using computer modeling techniques to achieve optimal performance and longevity. The ultrasonic blade must be tuned to match the system's frequency. This tuning process requires consideration of the blade head's mass, length, and geometry. Titanium, which has excellent anti-resonance and fatigue resistance properties, is the preferred material for ultrasonic blades. It also meets the hygiene requirements of the food processing industry. Due to the high stress associated with the thin, blade-like geometry required for ultrasonic cutting blades, they should be manufactured using wire EDM machines followed by stress-relief processes to maximize tool life.

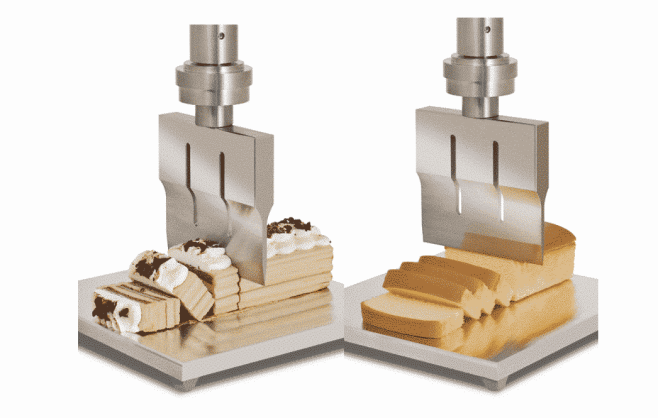

The blade head of an ultrasonic food cutting knife

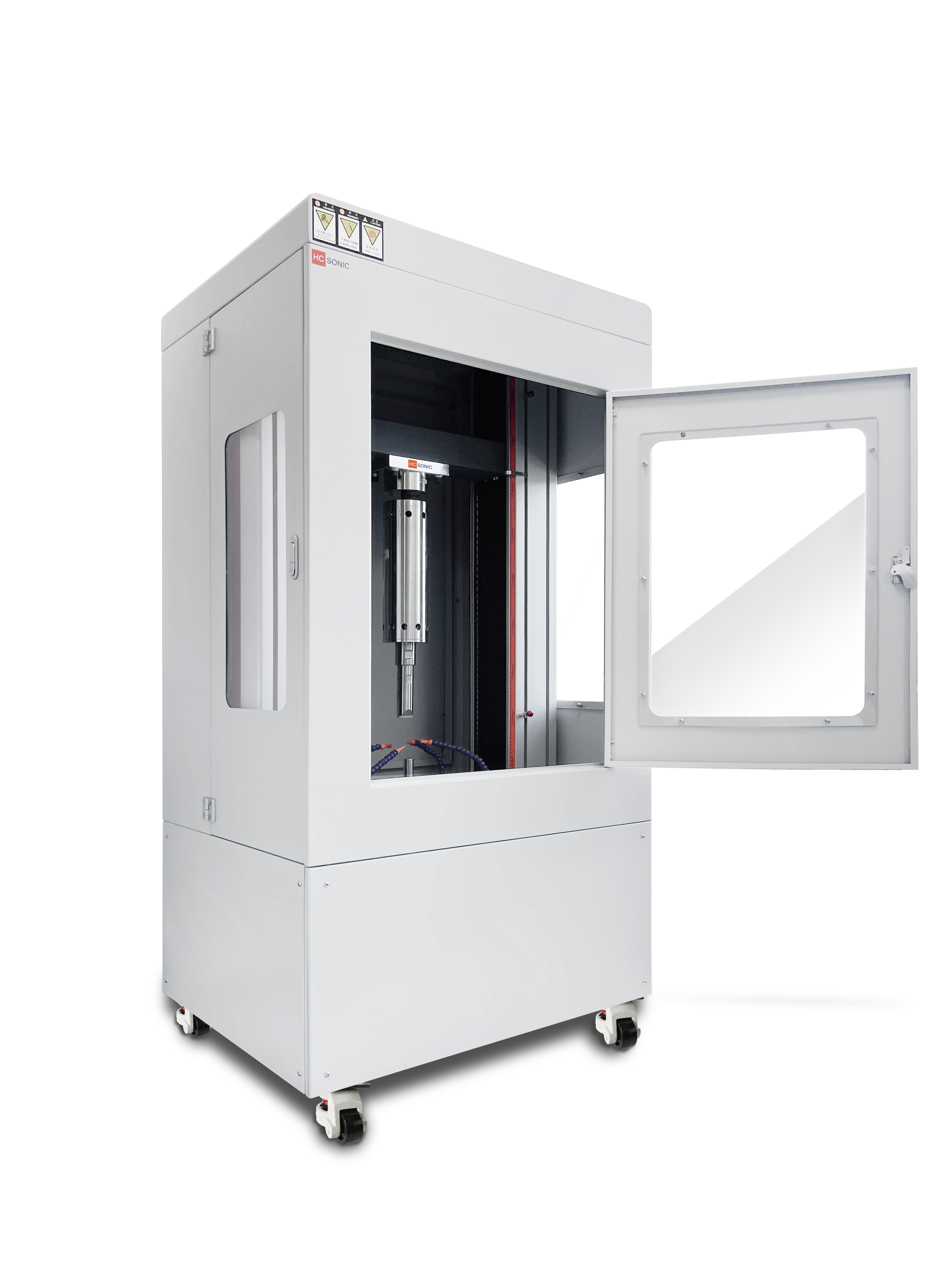

Material cutting system

Proper positioning and movement of food and ultrasonic blades require automated machines. Automation is crucial for achieving the correct cutting position, direction, and speed. Typically, these processing systems utilize servo-driven mechanisms to precisely control the speed and position of the food and cutting tools.

Three-axis ultrasonic cutting machine

Factors to consider during food cutting

--equipment startup time

Due to the need for a narrow blade design, the design and manufacture of ultrasonic cutting tool heads are challenging. Vibration of the blade at maximum amplitude without load sometimes leads to premature damage of the blade. Therefore, the signal from the ultrasonic generator should be synchronized with the automated machine to ensure that the blade reaches full vibration before it comes into contact with the food. Vibration prior to contact is necessary to avoid deformation of the food, which would occur due to contact with a non-vibrating cutting surface.

--vibration amplitude

The term 'amplitude' describes the microscopic displacement of the tool head's surface vibration during cutting. Amplitude is mechanically adjusted by the ultrasonic horn and digitally regulated by the ultrasonic generator. The size of the amplitude affects the cutting process and must be adjusted to meet the needs of each application.

--cutting speed

The speed at which the ultrasonic cutting blade enters and advances through the material being cut is also a process variable that should be adjusted for each cutting process. Sometimes it is necessary to slowly penetrate the product's outer shell to avoid deformation, and then increase the speed of the cutter within the product to achieve optimal cutting results.

--Vibration end time

Depending on the consistency of the material being cut, the completed slice may tend to adhere to the side of the cutting blade after the ultrasonic vibration is turned off. Therefore, maintaining ultrasonic vibration when removing the tool head from the product can utilize the frictionless characteristic to release the cutting blade cleaner and more consistently.

The appeal of ultrasonic food cutting

--Cleaner cuts: Always produces clean and even cut surfaces, cutting multi-layered composite foods (sandwiches) and nuts without causing displacement.

--Precision cutting of difficult-to-process products: easily slice items such as natural food cakes without deformation or breakage, as well as hard bread and bagels.

--Higher productivity leads to greater production volume: Ultrasonic systems offer faster cutting speeds compared to traditional blade systems, and smaller cuts help reduce waste.

--Reduce cleaning downtime: Ultrasonic systems offer longer operating time during the cleaning cycle and are easy to clean, thereby reducing cleaning downtime by 70% to 90%.

--High-quality materials meet the highest standards of the food industry: The equipment is made from stainless steel and titanium to ensure improved hygiene, safety, and processing performance.

--The smallest surface friction can extend the life of blades: ultrasonic tool head blades are sharper than stationary blades, increasing productivity and reducing maintenance.

The HCSONIC ultrasonic cutting system has been meticulously designed and manufactured to perform at high performance day in and day out, even in the most challenging processing environments.

Ultrasonic cheese cake cutting

Typical customer concerns about ultrasonic cutting blades

--Which foods can ultransonic waves cut?

--How long can my ultrasonic food cutting blade last?

--What should I do to maximize the lifespan of my cutting blade?

--Do I need to have my food cutting blade sharpened again?

In the face of the above issues, choose us:HCSONIC product features

Ultrasonic food cutting knives may not be suitable for all food cutting operations. However, the high-frequency vibrations applied to cutting tools do indeed offer significant advantages. Ultrasonic food cutting is not necessarily suitable for all food cutting tasks. Nevertheless, applying high-frequency vibrations to knives does provide notable benefits. First, ultrasonic technology improves cutting quality and consistency, and it provides the ability to cleanly slice soft foods without deformation. HCSONIC can evaluate key factors in food cutting operations to determine if the low-friction cutting surface of an ultrasonic knife is appropriate.

The effect of cutting wafers using ultrasonic waves

A bright future

Driven by an innovative culture, we will continuously improve our products and develop new applications to enhance our food processing capabilities. The food processing application currently under testing uses ultrasonic technology to enhance food flavors, tenderize meat, and release vitamins from food. We believe that by continually expanding and refining our capabilities, we can help our customers achieve better results.

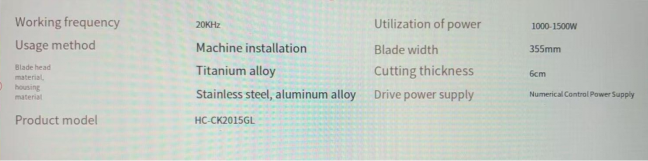

Product specifications are as follows: