The ultrasonic fatigue testing system is used to measure the fatigue properties of metallic materials

- Overview

- Recommended Products

Product Description

With the development of industrial technology, the design fatigue life of many metal parts has gradually increased. High cycle fatigue behavior of metal materials has become a research focus. Metal fatigue is a weakening of metal parts of machines, vehicles or structures due to repeated stress or loads.In response to the requirements of modern mechanical equipment parts for ultra-long service life and ultra-high reliability, traditional fatigue testing techniques have been unable to meet current demands.

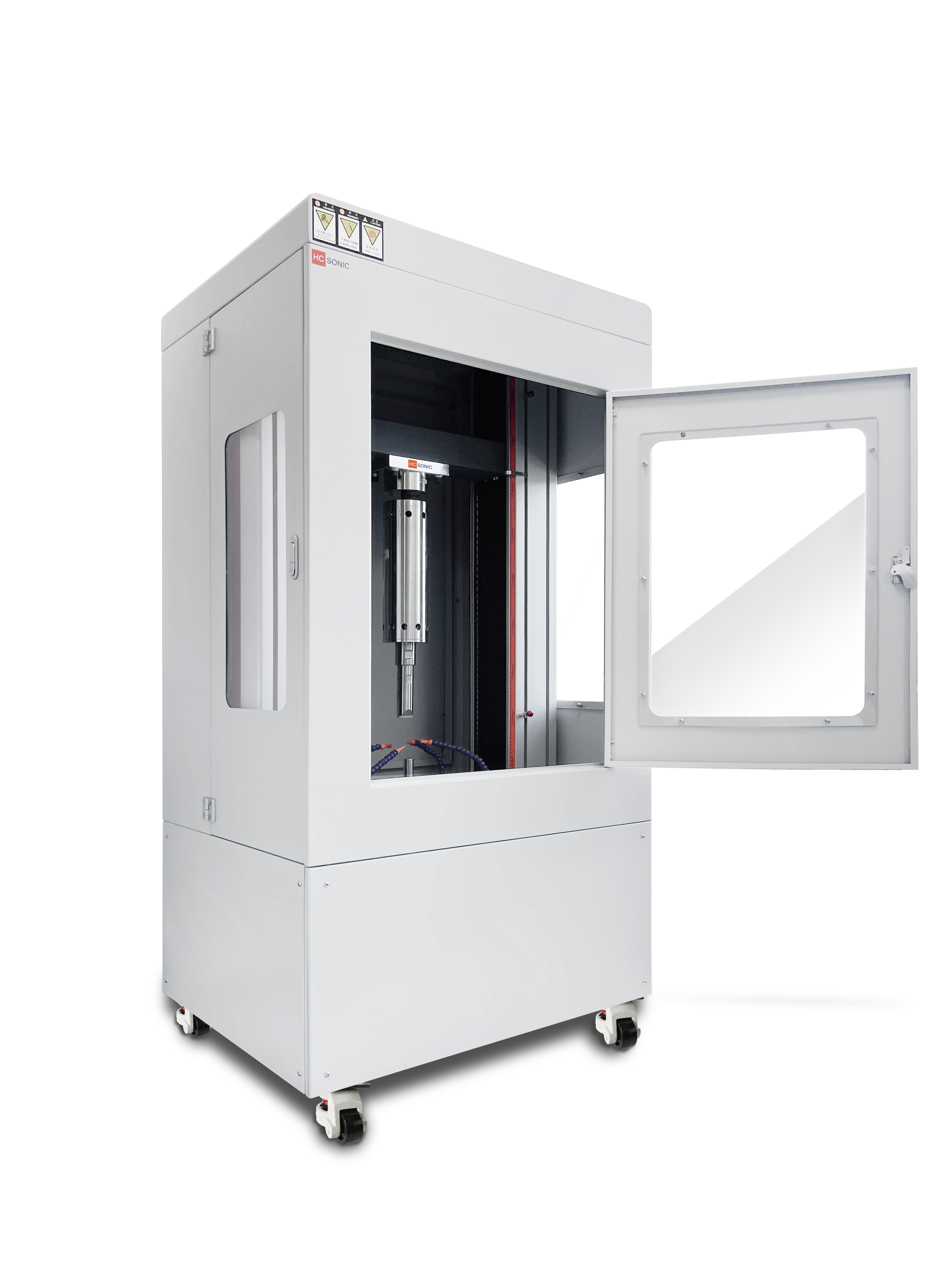

The ultrasonic fatigue testing machine produced by our company is used to measure the fatigue characteristics, fatigue life, pre-existing cracks and crack propagation of metals, alloy materials and their components under tensile, compressive or alternating tension-compression loads at room temperature.

Ultrasonic fatigue testing is an accelerated resonance-based fatigue testing method, which can significantly shorten the testing time and is the only feasible solution for ultra-long-life fatigue testing of aircraft engine blades.

The ultrasonic fatigue testing machine is a high-end testing equipment developed by our company based on the accumulation and inheritance of over ten years in the four core technologies of static pressure support, measurement and control, sensors, and application software. Through repeated iterations and upgrades, we have successfully overcome key technical difficulties such as strain control, coaxial adjustment measurement, and fatigue test data acquisition and processing in dynamic testing. It features a wide range of applications, high control accuracy, strong adaptability, flexible test methods, a wide frequency range, and the ability to simulate complex environmental conditions. It is widely used in dynamic high-cycle fatigue, low-cycle fatigue, programmed fatigue, as well as static constant deformation rate, constant load rate, and various conventional mechanical property tests. It meets the needs of different materials and components in high-end fatigue, fracture, and other testing fields, and is stable and reliable for a long time, filling the domestic gap.

Equipment parameters | |||

working frequency |

20KHz±1KHz |

service power |

2000W |

frequency resolution |

1Hz |

Waveform distortion degree |

<1%(20KHz正弦波) |

Output amplitude |

±10~±75μm |

control accuracy |

1μm |

degree of linearity |

>99% |

driving power |

Numerical Control Generator |

operating mode |

Continuous or intermittent work |

|

Product Parameters |

Product Details

The ultrasonic fatigue testing machine is used to determine the fatigue characteristics, fatigue life, pre-crack formation, and crack propagation of metals, alloys, and components under room temperature conditions under tensile, compressive, or alternating tensile-compressive loads.

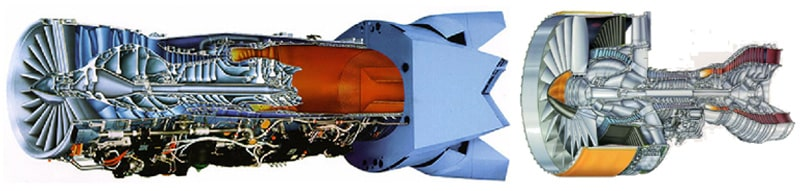

To meet the modern requirements for extremely long life and ultra-high reliability of mechanical components, traditional fatigue testing techniques are no longer sufficient. Ultrasonic fatigue testing is an accelerated resonance-based fatigue testing method that significantly reduces test time and is the only viable solution for the ultra-long-life fatigue testing of aircraft engine blades.

The significance of conducting metal fatigue tests

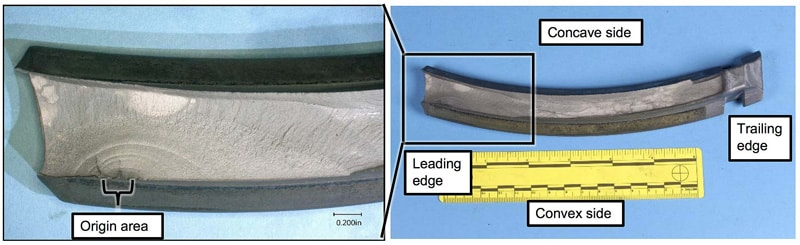

1.Metal fatigue caused the airplane crash.

Metal fatigue caused the airplane crash

On April 17, 2018, Flight 1380 (Boeing 737-700) from New York-LaGuardia Airport to Dallas Love Field Airport had a window that was breached and an engine that was damaged.

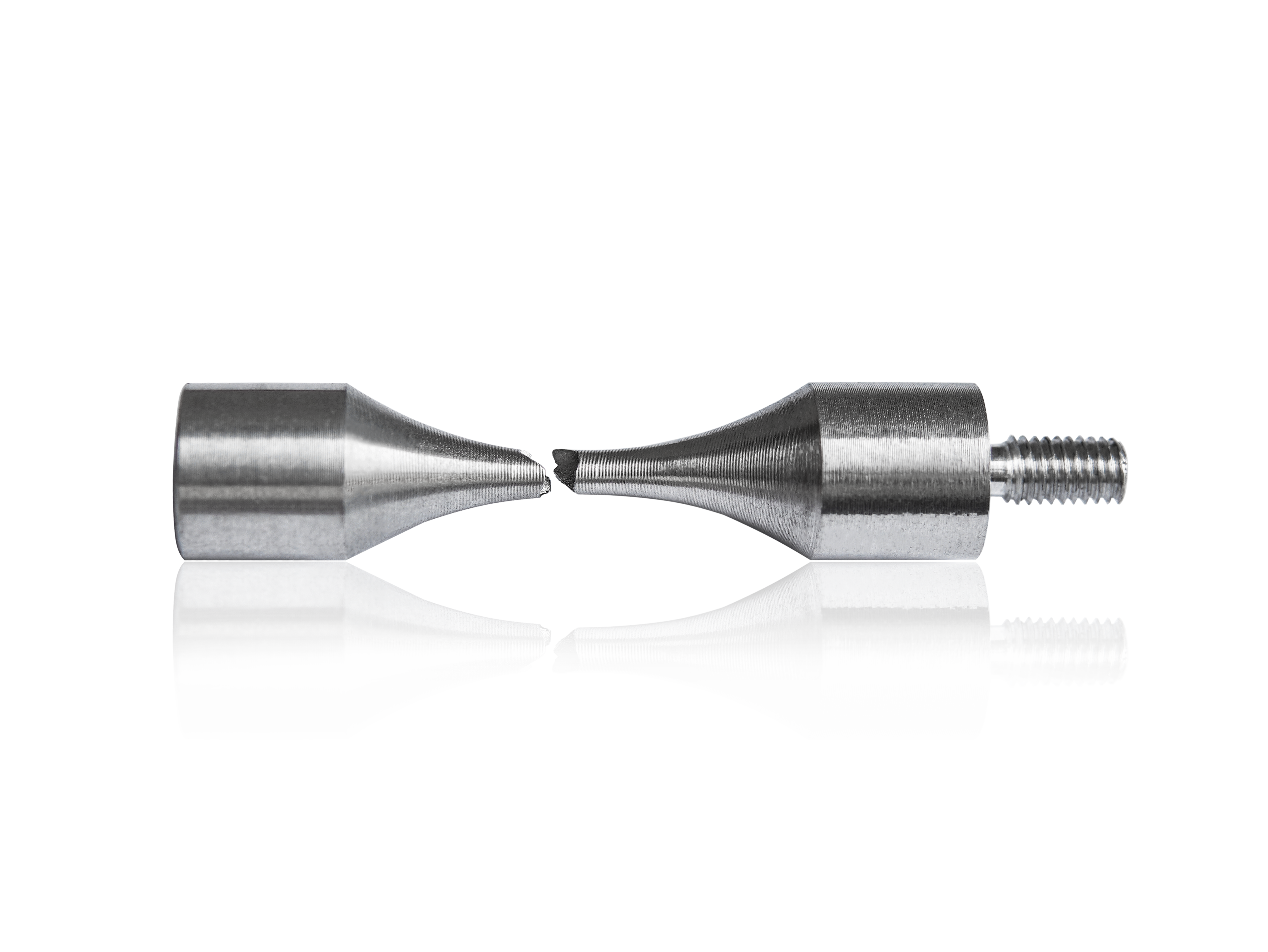

The 13th fan blade of Engine No. 1 was lost. Evidence indicates that the area where the blade broke showed signs of metal fatigue. The fan blades of the accident engine had accumulated over 32,000 engine cycles since their new installation. The fracture surface with fatigue indications.

2.Importance of Metal Fatigue Testing

Aerospace gas turbine engines are the primary power units for aircraft and helicopters, and they are key equipment that has long restricted the development of China's aviation industry and military equipment. Aerospace engines are high-speed rotating machinery with multiple rotors and extremely variable operating conditions. Their components, especially blades and discs, endure very complex vibration loads.

PW4084 engine, installed on Boeing 777 passenger aircraft

Material fatigue problems caused by vibration loads are key issues that restrict the high reliability and long service life of aero-engine, and have long troubled the research, development, production, and safe operation of China's aero-engines.

crashed aircraft and engine

3.blade fatigue factors

High Cycle Fatigue (HCF) and Very High Cycle Fatigue (VHCF) are primarily caused by vibration stresses induced from various aerodynamic and mechanical sources, with frequencies reaching thousands of hertz. These can lead to fatigue fractures in critical engine components such as fan blades, compressor blades, turbine blades or discs, and ducts, potentially resulting in flight accidents.

--internal flow disturbances in an engine

--Self-excited vibration (flutter and buffeting flow separation)

--Flow distortion (pressure)

--Rotor imbalance

Principle of Ultrasonic Fatigue Test

Ultrasonic fatigue testing is an accelerated resonance-based fatigue testing method that establishes mechanical resonance waves on the loaded specimen. Based on the piezoelectric expansion principle and utilizing high-energy ultrasonic resonance technology, its test frequency (20 kHz) far exceeds conventional fatigue test frequencies. Within the actual test time, it can obtain fatigue data and threshold values. Due to the high frequency, it can quickly detect the high-repetition cycle fatigue limits of various industrial materials.

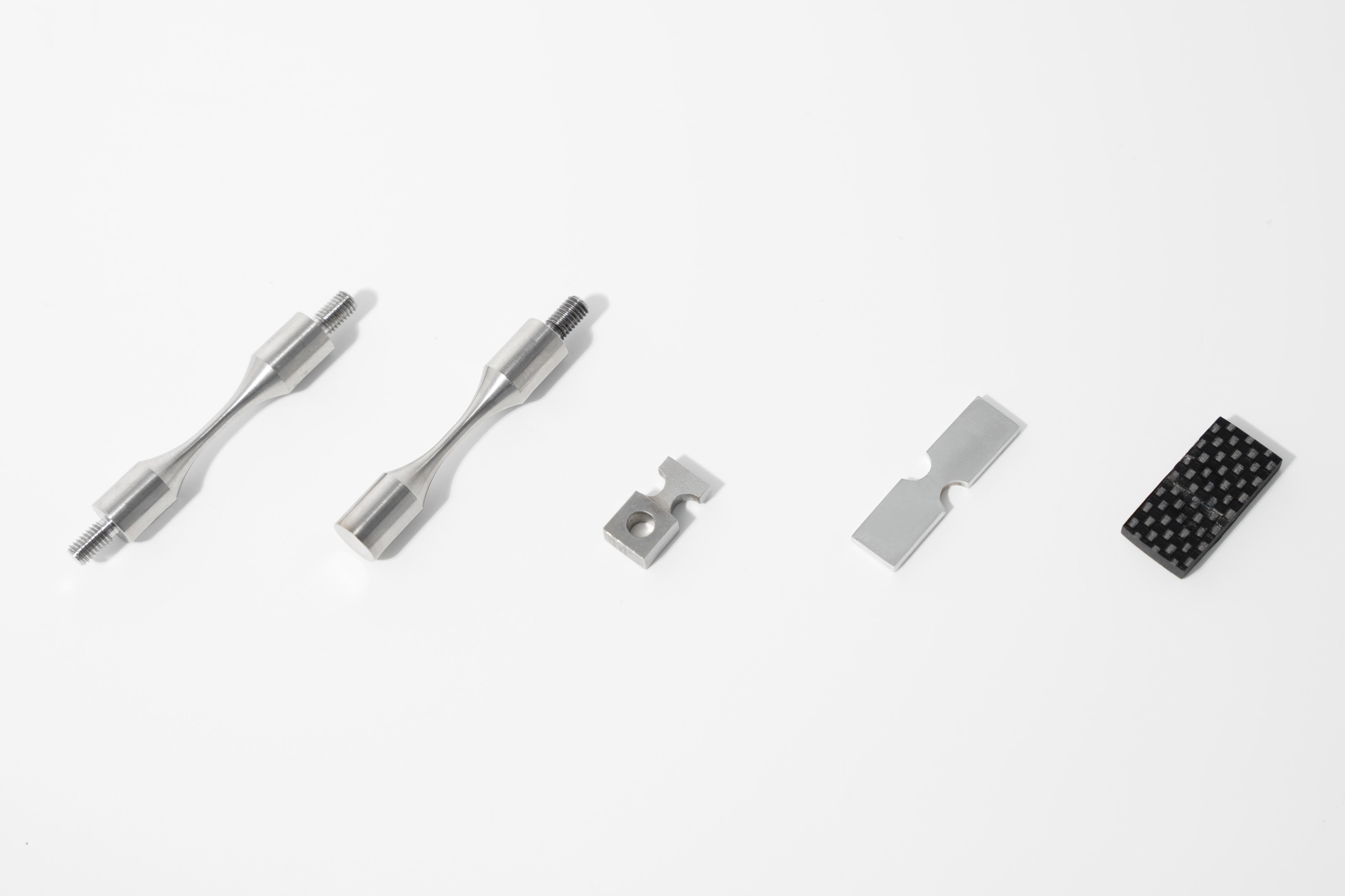

In response to modern mechanical equipment parts' ultra-long life and ultra-high reliability requirements, ultrasonic fatigue testers, based on ultrasonic resonance principles, generate high-frequency vibration loads on specimens to complete (super) high-cycle fatigue performance tests. The third-generation multifunctional ultrasonic fatigue tester developed by our company features a wide working frequency range, large output amplitude, and high control precision. It can conduct various forms of ultrasonic fatigue tests on metallic and composite materials, including variable stress ratio axial symmetric tension-compression, variable stress ratio three-point bending, and vibratory bending, among others. Additionally, it provides auxiliary optimization design software for various types of specimens such as axial tension-compression, three-point bending, and vibratory bending.

The advantages of ultrasonic fatigue testing

It can perform random amplitude loading, including low-level loads, thereby more closely approximating real engineering conditions.

Using computer-set parameters and control for experiments allows for the simple reproduction of fatigue failure caused by minor defects.

Due to the tests being conducted in a resonant state, high stresses can be generated, allowing for testing of steel with strengths up to 1000 MPa.

The required output power for test equipment is very low (tens of watts to hundreds of watts), which can significantly save energy and reduce testing costs.

The stress level at the ends of the specimen is very low during resonance, which simplifies the clamping of the specimen, requiring clamping at only one end. This is advantageous for brittle materials.

Rapidly evaluate the fatigue life of metallic materials at a repetition frequency of 20 kHz, reducing the testing time by hundreds to thousands of times.

For example, using the 109 fatigue test: A servo-hydraulic fatigue test at 20Hz requires 1.5 years; a rotating bending tester at 50Hz needs 231 days; a high-frequency vibration table at 300Hz takes 38.5 days; an ultrasonic fatigue test at 20kHz only requires 13.8 hours.

The ultrasonic fatigue test method is mainly applied

Primarily applied in aerospace, high-speed rail, automotive, and power plant sectors, it conducts ultra-high cycle fatigue performance tests on various metal materials such as alloy steel, aluminum alloys, and titanium alloys, as well as carbon fiber composite materials. Compared to conventional fatigue testing methods, it can reduce test time by over 90%, significantly saving testing costs.

Equipment parameters | |||

working frequency |

20KHz±1KHz |

service power |

2000W |

frequency resolution |

1Hz |

Waveform distortion degree |

<1%(20KHz正弦波) |

Output amplitude |

±10~±75μm |

control accuracy |

1μm |

degree of linearity |

>99% |

driving power |

Numerical Control Generator |

operating mode |

Continuous or intermittent work |

|

Product Parameters |