Ultrasonic dip welding does not require flux, save time and cost while reducing corrosion and increasing durability of solder joints

- Overview

- Recommended Products

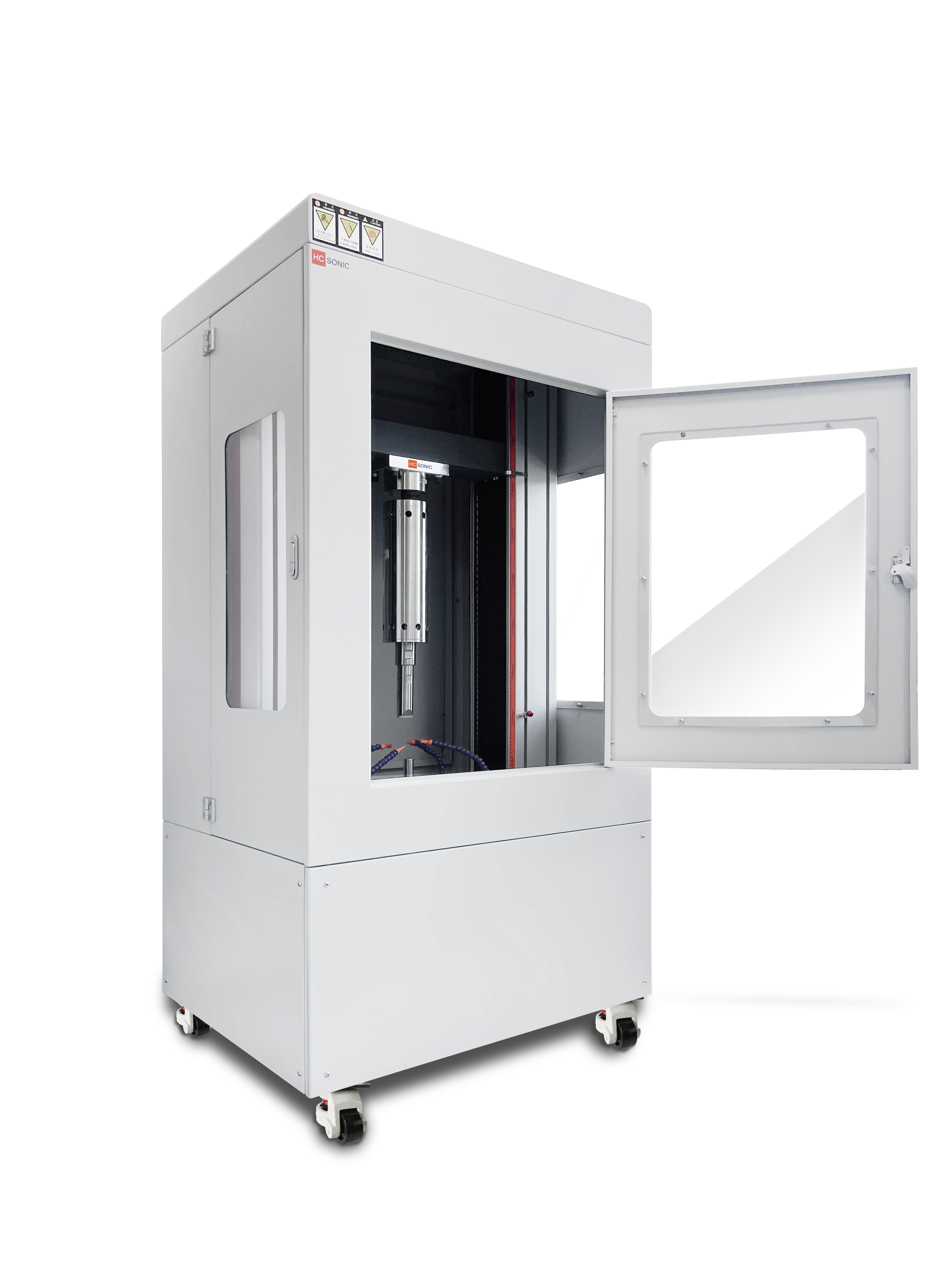

Product Description

Ultrasonic dip welding allows welding of different materials and can be used to weld materials that are difficult to weld by conventional methods. Because it does not require flux, users can save time and cost on cleaning flux residues while reducing corrosion and increasing durability of solder joints.

Product Details

Overall technical specifications:

The rated power of the ultrasound equipment |

1000W |

total rated power |

1×1000W=1000W |

operating frequency |

20.0±0.5kHz |

input voltage |

220V/50Hz |

Overall equipment dimensions |

See attached diagram |

Total equipment weight |

About 25 kilograms |

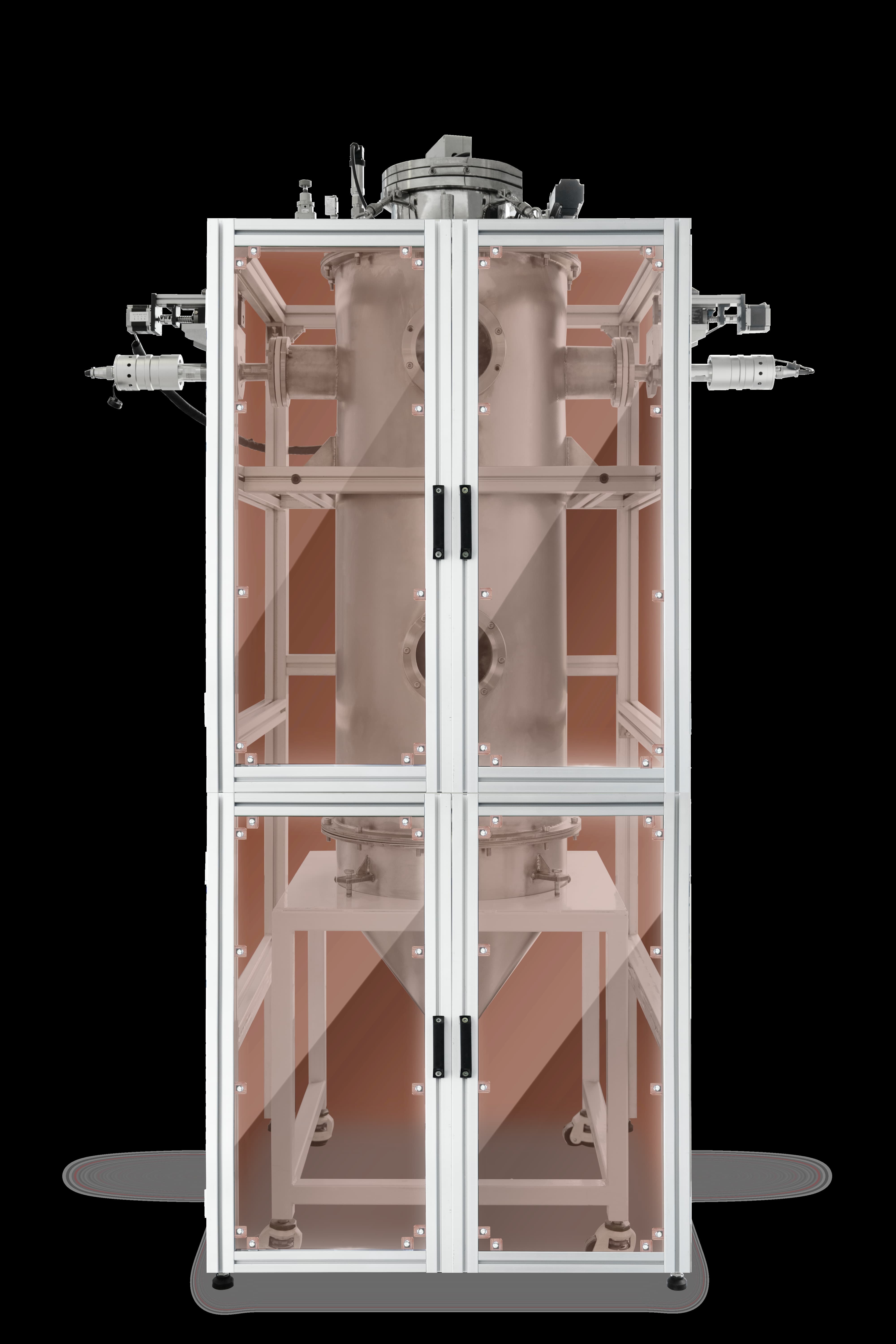

Vibration component parameters

The function: Convert electrical energy from the ultrasonic drive power supply into mechanical energy of ultrasonic vibration, radiating ultrasound.

Ultrasonic wave soldering equipment | ||||

|

Components and quantities (Single vibration unit) |

component name |

model or type |

core materials |

quantity/each |

|

Components and quantities (Single vibration unit) |

Furnace |

X-008 |

stainless steel |

1 |

|

Components and quantities (Single vibration unit) |

transducer |

JZ2050-4D |

piezoelectric ceramic |

1 |

|

Components and quantities (Single vibration unit) |

Variable amplitude rod |

HC-D20T |

Titanium Alloy |

1 |

|

Components and quantities (Single vibration unit) |

tool head |

HC-D20T20-40 |

alloy steel |

1 |

|

Components and quantities (Single vibration unit) |

Outer shell |

Protective casing |

stainless steel |

1 |

|

vibration component dimensions |

See attached diagram |

|||

Cooling method |

Internal fan cooling |

|||

Maximum temperature |

80℃ |

|||

Maximum pressure |

0.6 Mpa |

|||

Vibration power |

1000W/unit |

|||

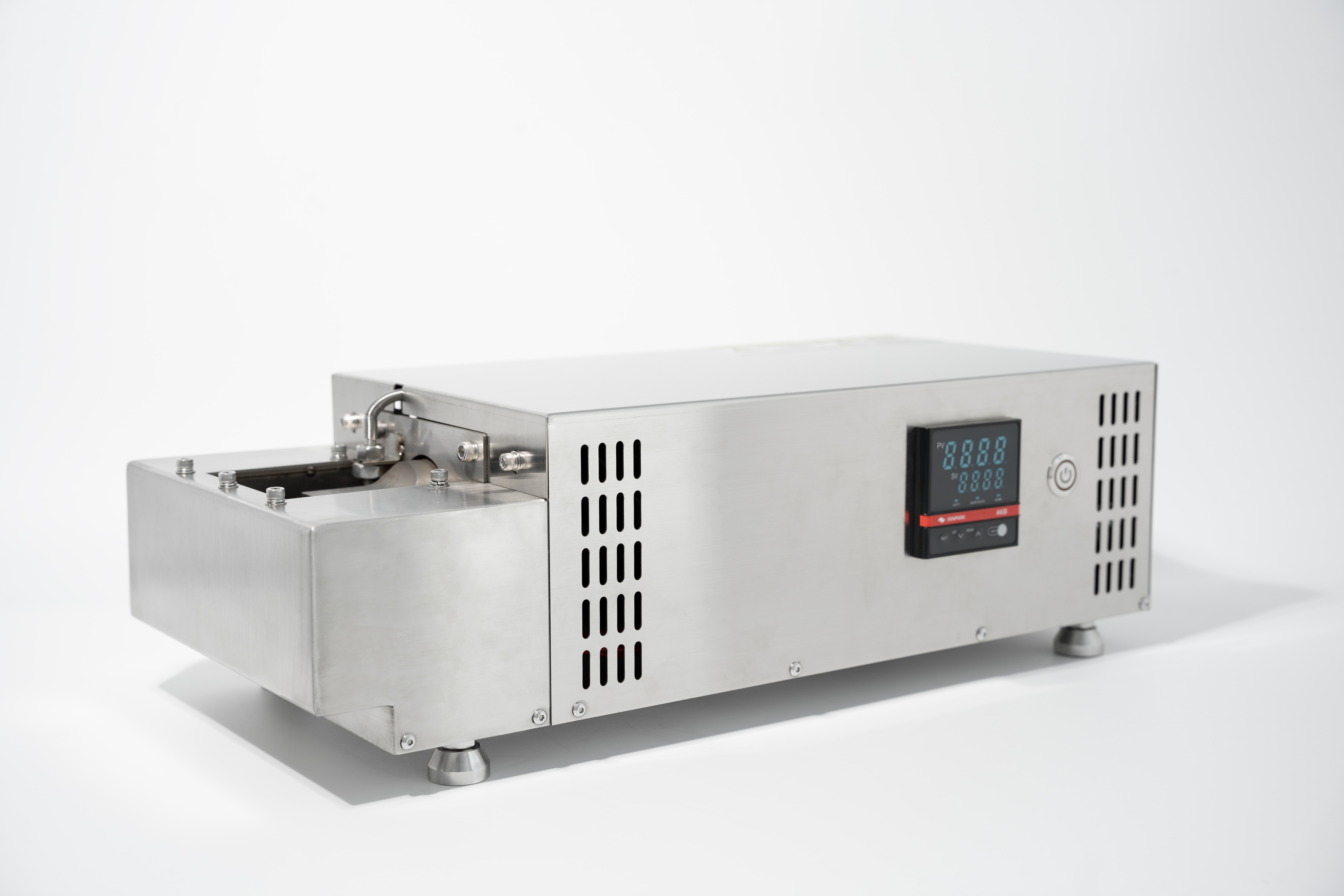

Drive power supply parameters

Function: Generates high-power, high-frequency AC energy, fully digitally controlled, driving the ultrasonic vibration components to operate.

Drive power model |

power control cabinet |

|

Structural component |

name |

quantity |

Structural component |

power module |

1set |

Structural component |

control assembly |

1set |

primary function | ||

monitoring parameters |

work status, frequency, power |

|

parameters set autonomously |

Ultrasonic output power can be set autonomously. |

|

tracking mode |

Automatic |

|

Automatic amplitude control |

During operation, when the load changes, automatically adjust the drive characteristics to ensure stable output amplitude. |

|

system protection |

High temperature protection, overcurrent protection |

|

power adjustment method |

continuously adjustable |

|

Human-computer interface |

Encoder adjustment |

|

Method of operation |

work continuously |

|

control circuit type |

digital

|

|

Frequency scanning method |

Pulse-triggered |

|

Frequency adjustment range |

19.5-20.5kHz |

|

Utilize ambient temperature |

room temperature |

|

input voltage |

220V / 50Hz |

|

Dimensions (length * width * height) |

Please see the attachment. |

|

The connection method of the vibrating component |

High-voltage cables and aviation connectors |

|