- Overview

- Recommended Products

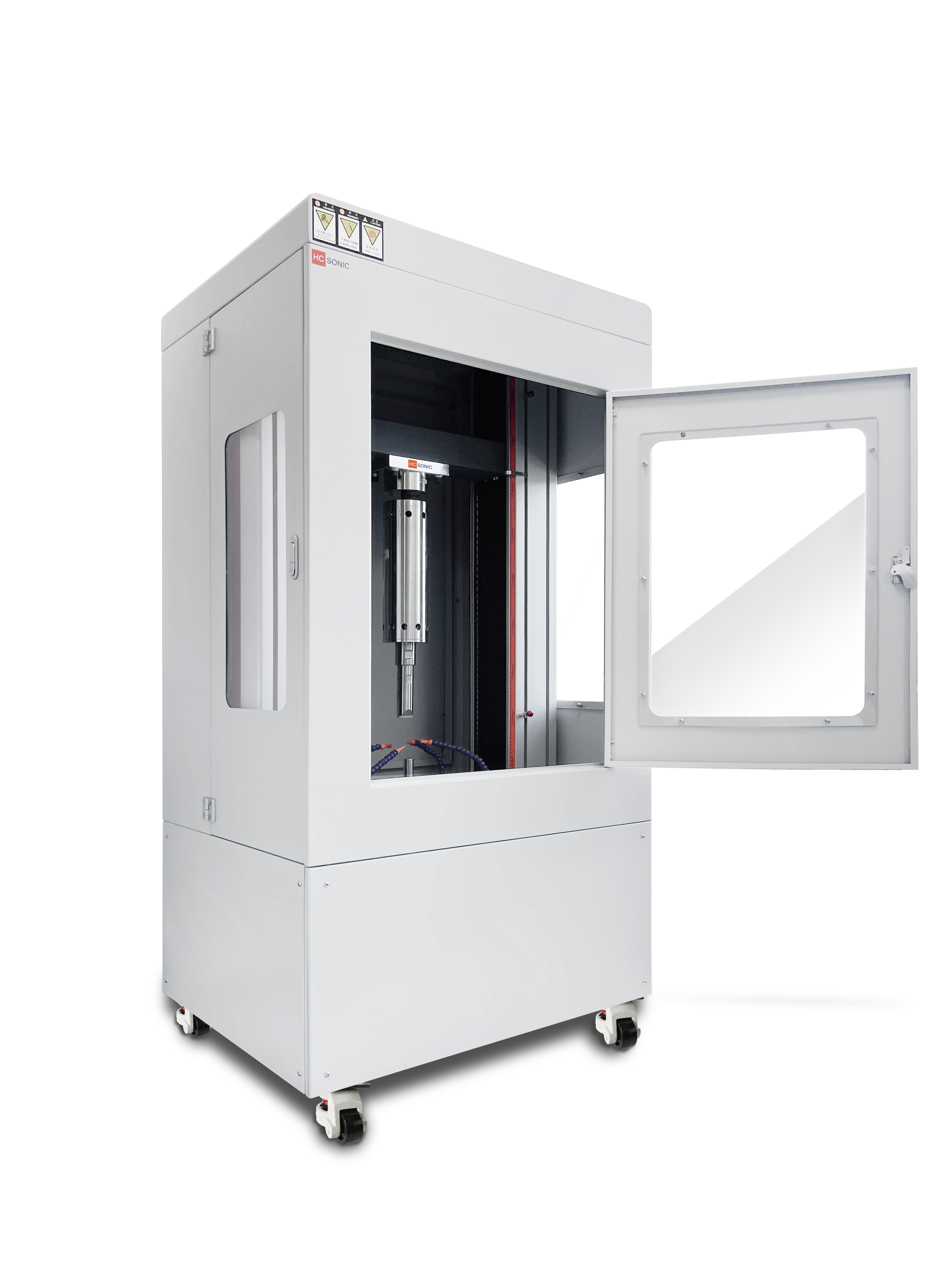

Product Description

Ultrasonic emulsification equipmentcan use ultrasonic energy to mix two or more incompatible liquids together, one of which is evenly dispersed in the other liquid to form an emulsion-like liquid. A wide variety of intermediates and consumer products, such as cosmetics and skin care products, pharmaceutical ointments, paints, lubricants and fuels, are all complete or partial lotions and can be prepared using ultrasonic emulsification equipment. Emulsions are found in every aspect of life, and understanding how to control and optimize performance is essential to the production of high-quality products, and quality is defined as suitable for the final application.

Product Details

Ultrasonic emulsification equipment

Introduction to Emulsification

Different industries have significant variations in the manufacturing processes of emulsions, which include the components used (mixtures, including various ingredients in the solution), emulsification methods, and additional processing conditions. An emulsion is a dispersion of two or more immiscible liquids, and ultrasonic emulsification equipment provides high-intensity ultrasonic energy to disperse the liquid phase (disperse phase) into small droplets within the second phase (continuous phase), requiring the necessary energy.

Two liquids can form different types of emulsions. For example, oil and water. First, there is an oil-in-water emulsion, where oil is the dispersed phase and water is the continuous medium. Second, they can form a water-in-oil emulsion, where water is the dispersed phase and oil is the continuous phase. Additionally, multiple emulsions may also form, including 'water-in-oil-in-water' emulsions and 'oil-in-water-in-oil' emulsions.

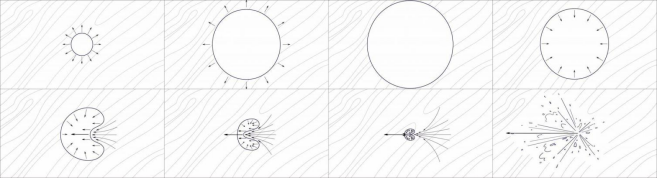

The ultrasound emulsification process

Diagram of the ultrasonic cavitation process

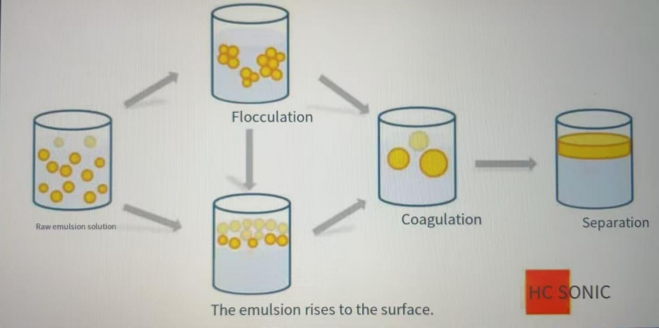

Emulsification fluid instability causes coalescence

Ultrasonic emulsification is caused by cavitation. Ultrasonic waves passing through a liquid cause it to continuously compress and expand. High-intensity ultrasonic waves provide the energy needed for the dispersion of the liquid phase. When maximum pressure is reached, liquid rupture occurs at points with weaker cohesive forces. Following this rupture, overpressure is observed at the point of rupture, and some cavities are found to exist. In these cavities, gases dissolved in the liquid explode as bubbles after a short time.

To stabilize newly formed dispersed phase droplets and prevent coalescence, emulsifiers (surfactants) and stabilizers are added to the emulsion. The final droplet size distribution is maintained at the same level as after droplet breakage in the ultrasonic dispersion zone.

The cavitation process is influenced by the frequency and intensity of ultrasound, and the occurrence of cavitation within the medium largely depends on the presence of undissolved gas in the liquid, where the presence of gas seems to act as a catalyst. At certain pressures, the formation of cavities to some extent depends on the development time and ultrasonic frequency. The ultrasonic emulsification process represents a competition between opposing processes. Therefore, it is necessary to select appropriate working conditions and frequencies so that the disruptive effect predominates.

To prepare oil-in-water emulsions, the threshold acoustic intensity required is significantly lower than that needed for water-in-oil emulsions. The type of acoustic field affects the emulsification process, specifically by applying a standing wave. Compared to applying some static waves, the process efficiency improves. This can be explained by the fact that in a static wave field, the opposite process to dispersion, namely coalescence, predominates.

Ultrasonic paraffin emulsification experiment

The advantages of ultrasonic

--It can control the type of emulsion.

--The power required to produce emulsion is small.

--The formed emulsion is more stable, some can remain stable for several months to over half a year.

--High concentration, pure emulsion concentration can exceed 30%, and with additional emulsifiers it can reach up to 70%.

--Low cost, one of the important features of ultrasonic emulsification is that it can produce very stable emulsions without or with minimal use of emulsifiers.

--Compared to general emulsification processes and equipment such as propellers, colloid mills, and homogenizers, ultrasonic emulsification has many advantages.

--The formed emulsion has small average droplet sizes (0.2 to 2 micrometers) and a narrow droplet size distribution range (0.1 to 10 micrometers) or even narrower.

HCSONIC emulsification equipment features:

HCSONIC ultrasonic emulsification equipment can consist of one or multiple ultrasonic processors with power ratings of over a thousand watts, effectively enabling the transition from laboratory applications to industrial production. It achieves results comparable to today's best high-pressure homogenizers, allowing for the continuous flow or batch processing of finely dispersed emulsions. The HCSONIC ultrasonic emulsification equipment has very low maintenance costs and is easy to operate and clean. The power of the ultrasonic emulsification equipment is adjustable, making it adaptable to specific emulsification requirements for different products.

HCSONIC product features

Ultrasonic emulsification equipment has replaceable tip tool heads (caps). The caps have hard threads at their ends that connect to the tool heads. When the caps wear out due to cavitation, they can be unscrewed and replaced.

(Note: If you perform ultrasonic treatment on solutions containing organic solvents, alcohols, or any liquids with low surface tension, the liquid will penetrate into the threaded tip's interior (regardless of how tightly it is connected). Once the liquid enters the tip, it will loosen and cause the ultrasonic instrument to overload. If you are handling samples containing solvents or low surface tension liquids, you must use a fixed-tip tool head, which can be used for any type of sample.)

equipment images

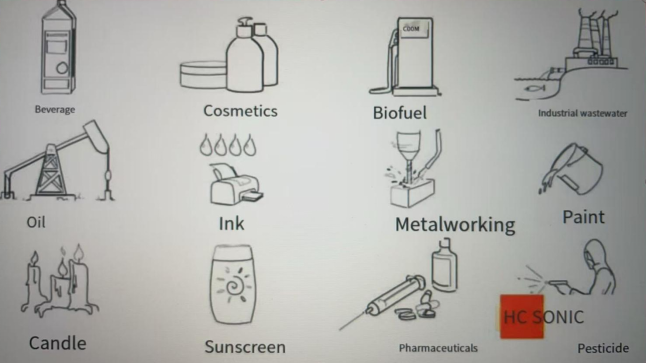

Ultrasonic emulsification applications

Ultrasonic emulsification equipment has been widely applied in various industrial fields such as food, papermaking, coatings, chemicals, pharmaceuticals, textiles, petroleum, and metallurgy. Ultrasonic devices can be easily installed on existing production lines, making it convenient for manufacturers to upgrade their equipment at a lower cost. Ultrasonic emulsification can also create emulsions that conventional methods cannot achieve. Common mixing methods can only produce 5% of paraffin in water, but surprisingly, under the effect of power ultrasound, 20% paraffin emulsion can be produced.

Product specifications are as follows: