Product Description

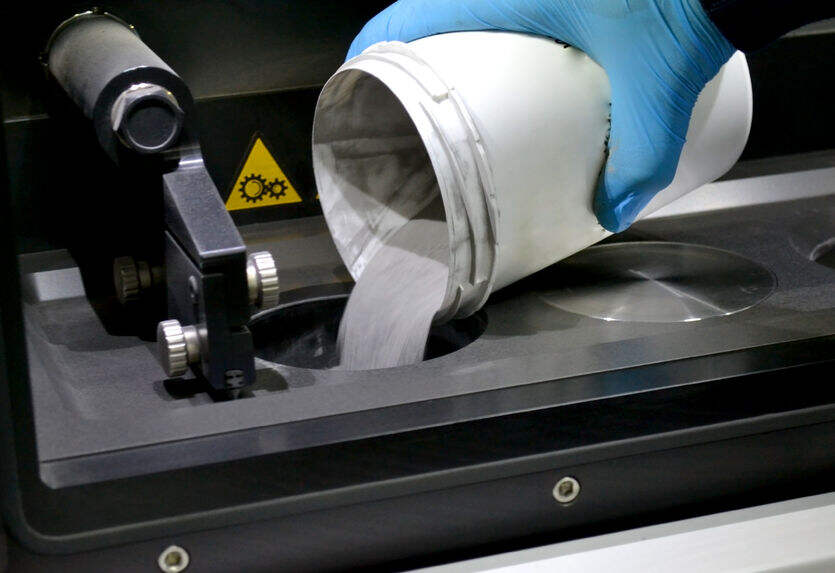

High - quality solder powder can ensure the stability and reliability of welding.

Basic Information

Definition: Solder powder is a metallic powder used for welding, mainly composed of metal elements such as tin, lead, silver, and copper, processed through special techniques. It is the main component of solder paste in surface mount technology (SMT).

Function: Primarily used to prepare solder paste. In the electronics industry, it connects electronic components (such as chips, resistors, capacitors, etc.) to printed circuit boards (PCBs), ensuring the electrical connection and mechanical fixation of electronic devices.