Indium-based alloy powder, a type of modified metal powder, enhances the strength, ductility, wear resistance, and corrosion resistance of metal alloys

- Overview

- Recommended Products

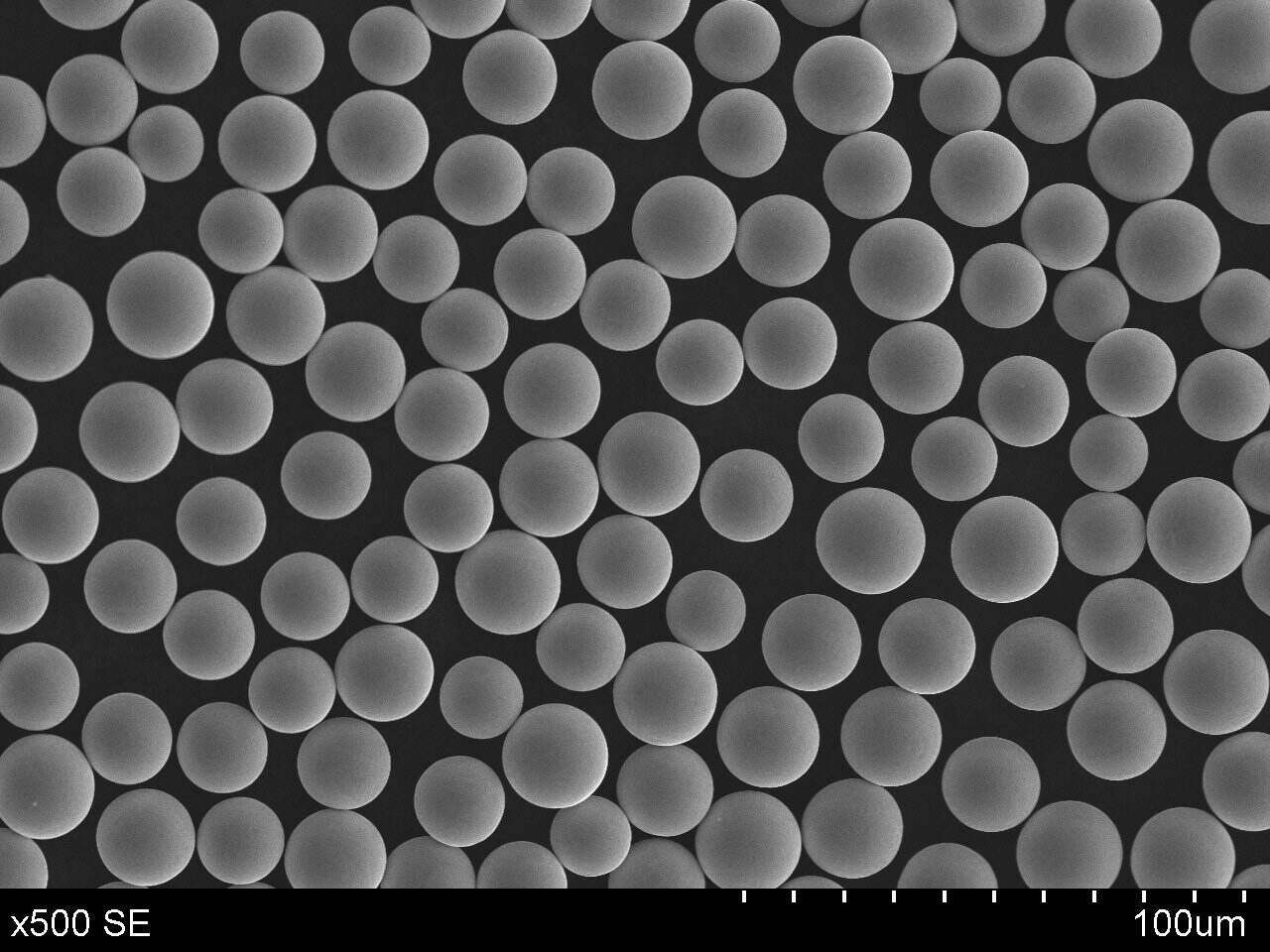

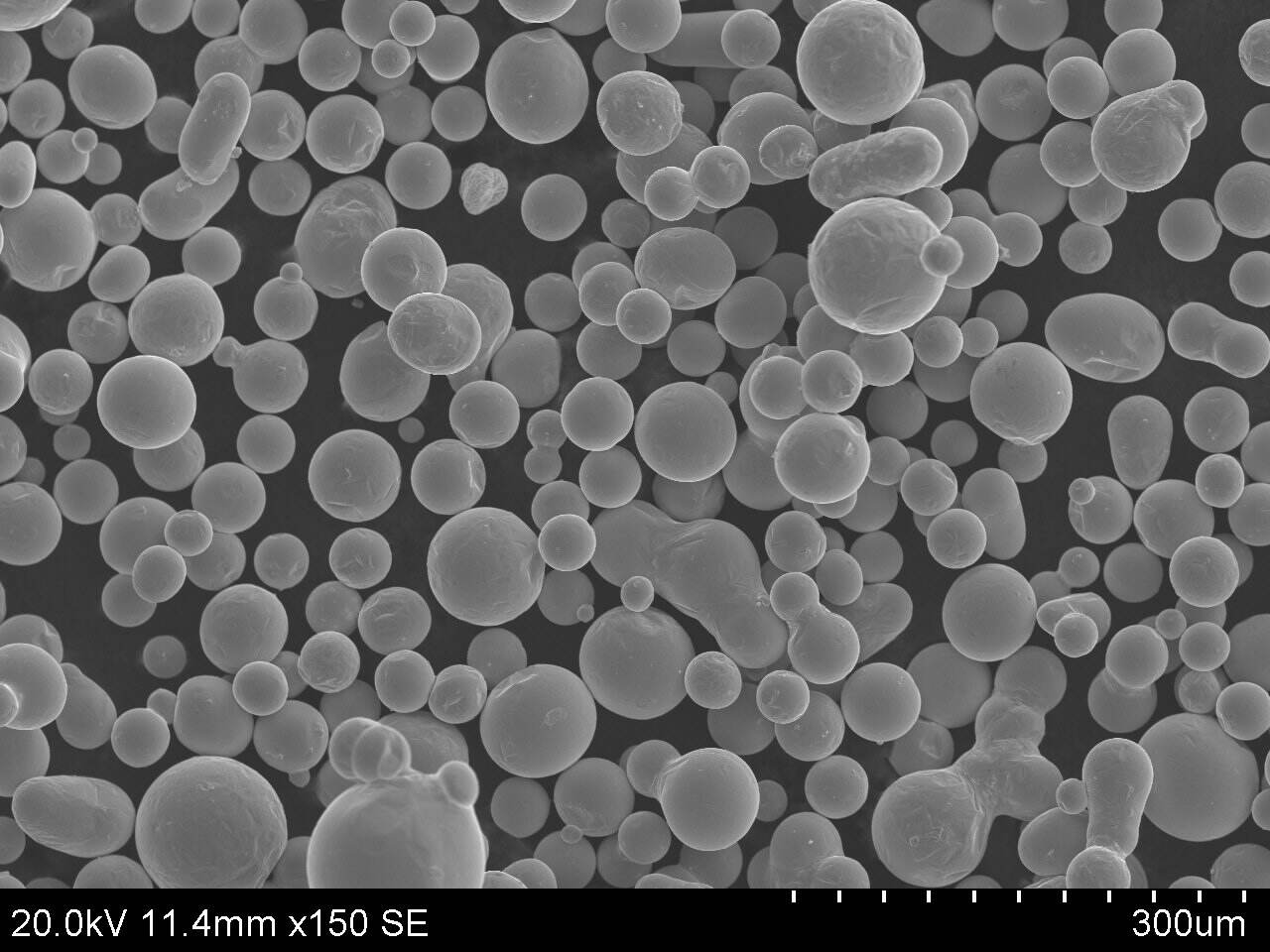

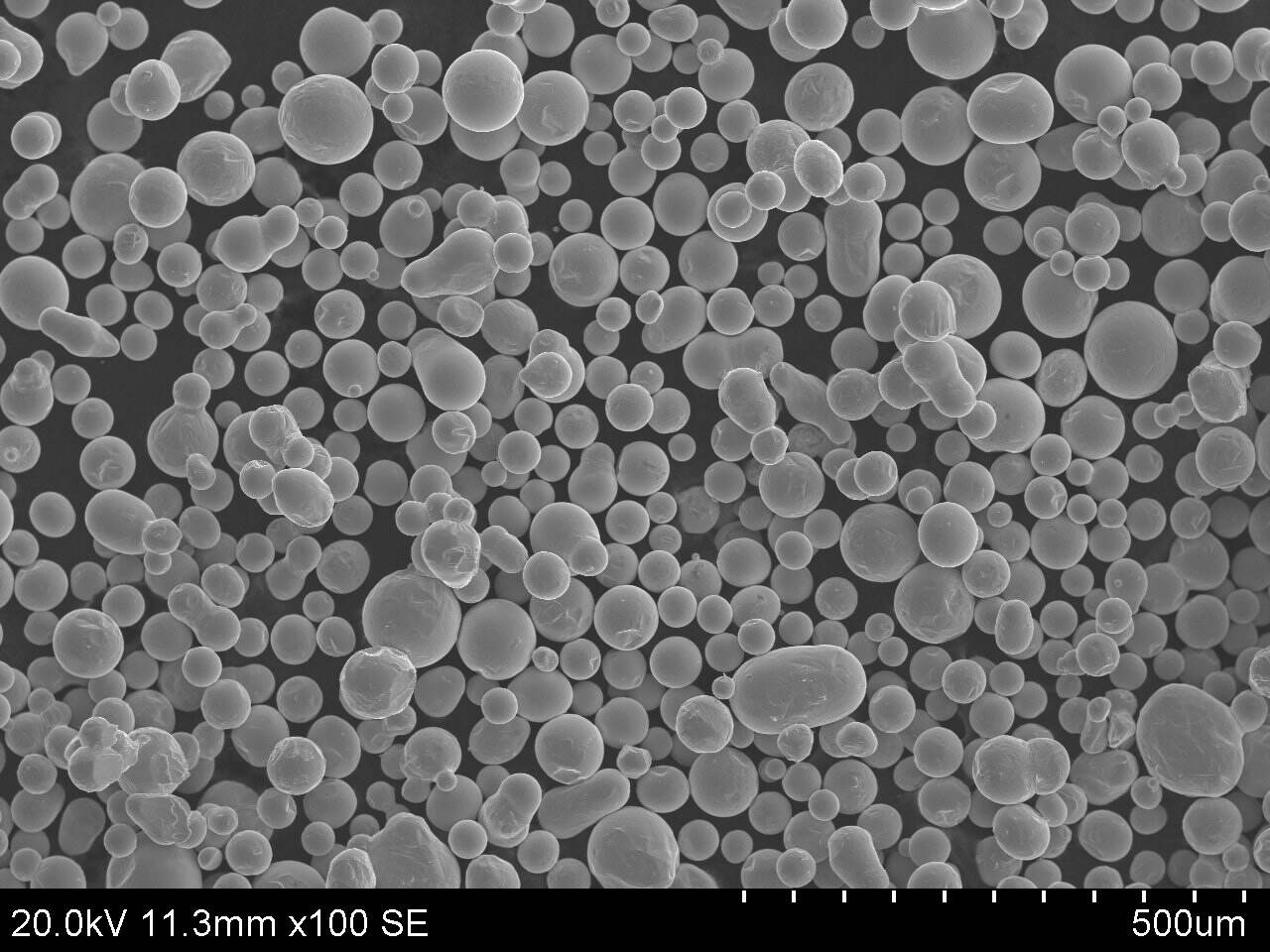

Micrograph Product Features

Excellent physical properties: Good fatigue resistance of solder joints, reliable mechanical strength and tensile properties. High corrosion resistance to alkaline and salt media, suitable for welding in chlorine-based industrial equipment.

Prevention of gold brittleness: When welding gold-plated products, if tin-based solder is used, the gold on the gold-plated components will be attracted, resulting in the formation of brittle metal compounds. Therefore, in this case, it is generally recommended to use indium-based solder, which can prevent the loss and penetration of gold and enhance the reliability of the solder joints.

Good conductivity and electrical heating properties: High conductivity. Indium-based solder has conductivity close to Sn-Pb alloys and higher conductivity, which can avoid signal loss on the solder joints and meet the requirements of electronic connections.

Good wetting ability with non-metals: Used for welding glass products, ceramic products, quartz products, ceramic products, etc. in electronics, low-temperature physics, vacuum systems.

Good compatibility: Has good brazing performance with copper, tin, silver, gold, nickel and other platings on PCB pads, component pins, etc. Additionally, it can also be compatible with different types of fluxes.

Wide melting point range: Depending on different ratios, different types of indium-based alloy powder products with melting points ranging from several degrees to over 300 degrees can be produced to meet the needs of different fields.

Uniform particle size: The particle size of the powder is controllable and uniform, meeting the relevant standards of GTB-29089-2012 for tin alloy powder used in electronic soldering.

Good sphericality: The representative alloys for low-temperature brazing of In are: In52Sn48 and In97Ag3.

Product Details

The following is an introduction to indium-based metal powders:

Composition and Classification

**Binary alloy powders**:

Composed of indium and another metal element, such as indium-tin alloy powder, indium-lead alloy powder, etc. In indium-tin alloys, the combination of indium's low melting point and tin's good conductivity and ductility endows the alloy powder with unique physical and chemical properties.

**Ternary alloy powders**:

Containing indium and two other metal elements, a typical example is indium-lead-silver alloy powder. This kind of alloy powder integrates the characteristics of the three metals, such as indium's low melting point, lead's good fluidity, and silver's high conductivity and corrosion resistance.

**Multicomponent alloy powders**:

Composed of indium and various other metal elements, their composition is more complex. They can be designed to have specific properties according to specific needs, so as to meet the application requirements in different fields. ### Characteristics

**Low melting point**:

Indium has a relatively low melting point of 156.6°C. After forming an alloy, the melting point of indium-based metal powder is usually also low, which can realize melting and welding at a lower temperature, avoiding thermal damage to other components during processing.

**Good wettability**: It has good wetting ability to both metals and non-metals. In welding or coating applications, it can well adhere to the surface of the base material, forming a firm bond.

**Excellent electrical and thermal conductivity**:Indium itself has good electrical and thermal conductivity. After forming an alloy with other metals, these properties are still maintained to a certain extent, making it of great application value in the field of electronics and electrical engineering.

**Corrosion resistance**: Some indium-based alloy powders have good corrosion resistance to specific media. For example, indium-based solder has good corrosion resistance to alkaline media and can maintain stable performance in harsh environments.

Preparation Methods

**Gas atomization method**: The molten indium-based metal liquid is atomized by high-pressure gas, broken into fine droplets, and then rapidly cooled and solidified in the air to form powder. The powder prepared by this method has a relatively large particle size and irregular shape.

**Centrifugal atomization method**: The molten metal liquid is ejected by the centrifugal force of high-speed rotation to atomize into powder. The powder prepared by this method also has the problems of large average particle size and irregular shape.

**Ultrasonic atomization method**: The molten indium-based metal liquid is broken into tiny droplets by the high-frequency vibration of ultrasonic waves, and then forms powder. Compared with the previous two methods, the powder prepared by ultrasonic atomization has better sphericity, which can effectively avoid the problem that a large number of small satellite powders adhere to the powder surface, and improve the quality and performance of the powder. Our company has adopted this manufacturing method.

Application Fields

**Electronics industry**:

Used in the manufacture of semiconductor devices, integrated circuit packaging, flat panel display coating, etc. For example, in integrated circuit packaging, the solder made of indium-based metal powder can realize a reliable connection between the chip and the substrate, ensuring the performance and stability of electronic equipment.

**Aerospace field**:

Can be used in the manufacture of aviation bearings, engine components, etc. Indium-based metal powder has good wear resistance, corrosion resistance and high-temperature stability, which can meet the use requirements of aerospace components under extreme conditions.

**Energy field**:

Has important applications in solar cells, lithium batteries, etc. For instance, in solar cells, indium-based compounds can be used as transparent conductive film materials to improve the photoelectric conversion efficiency of the cells.

**Welding and brazing**:

Due to its low melting point and good wettability, indium-based metal powder is often used as a welding and brazing material for connecting various metal and non-metal materials, especially suitable for welding temperature-sensitive components.

Our company, through its own advanced ultrasonic technology innovations, provides customers with high-quality indium-based metallic powders.