Product Description

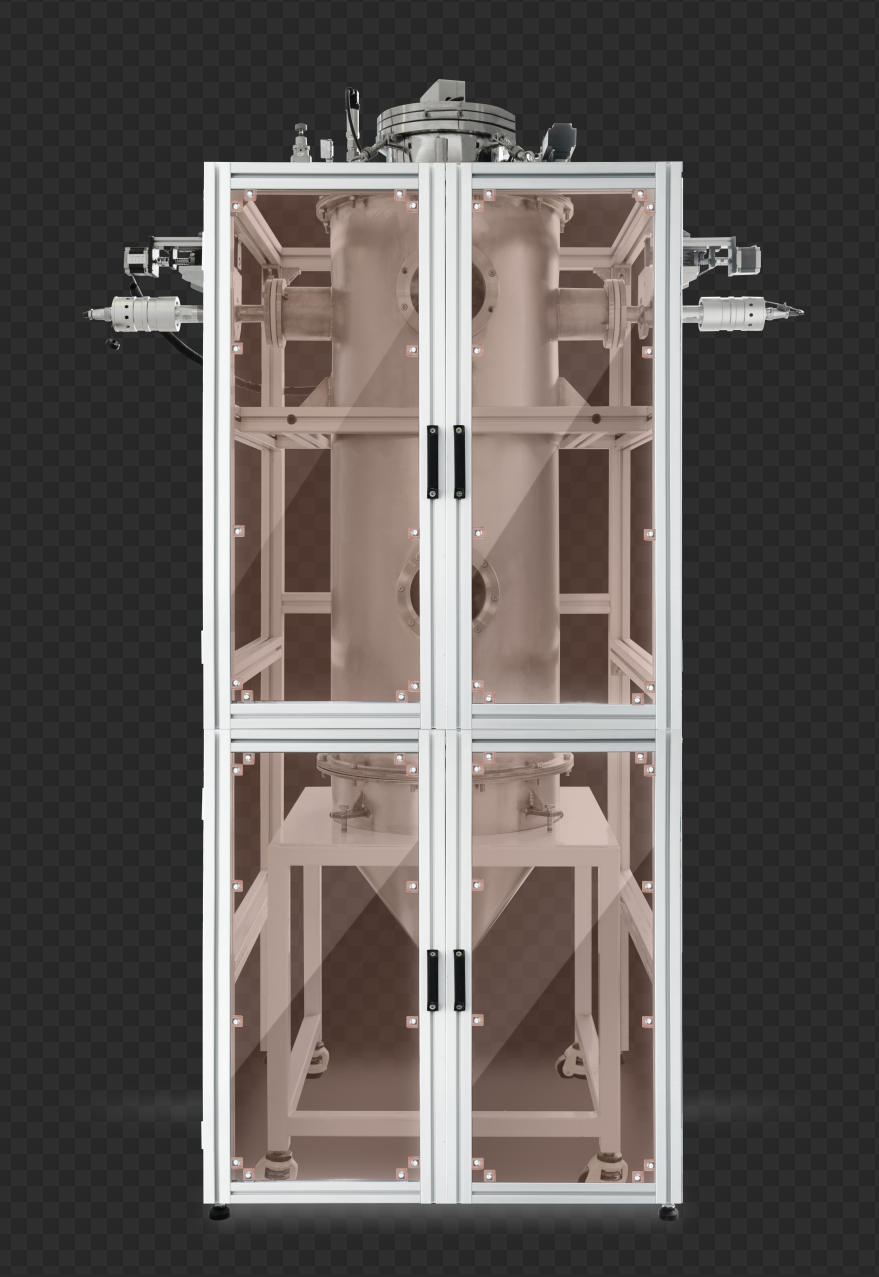

Our company has an ultrasonic metal powder production plant, which can provide processing services for customer-supplied metal powder. You provide the raw materials, and we provide the equipment for processing and powder production.

We also offer metal powder processing services, providing various raw material nanomodification processing services. We have products such as indium-based alloy powder, ultrasonic solder alloy powder, graphene powder, lithium battery graphene electrode materials, copper-based brazing powder, gallium powder, high-purity indium powder, etc.

According to user requirements, we can process and customize products of different particle sizes. At the same time, we provide corresponding product development technical solutions.