【 Get the most accurate answer in the least amount of time. 】

Ultrasonic fatigue testing generally refers to fatigue tests conducted at a repetition frequency of 15 to 25 kHz. Its main feature is that it can obtain data near the fatigue limit and threshold within the actual test time. Due to its high frequency, the ultrasonic testing method can quickly evaluate the fatigue limit of various industrial materials under high repetition cycles. Additionally, previous fatigue testing machines had complex clamping structures at both ends of the specimens, making them difficult to apply to tests on tubes, thin plates, and wires. However, with the ultrasonic testing method, as long as one end of the specimen is properly adhered or fixed with screws, thin materials can be tested under tensile and compressive loads without the risk of bending. In other words, the alternating fatigue tests that were previously difficult to perform have become easier. Moreover, by monitoring the input and output of the vibration stress transmission system and the resonance frequency, the changes in internal friction and elastic constants during fatigue testing can be determined. This enables the acquisition of a wealth of information about material changes during fatigue testing.

Take the 10⁹ fatigue test as an example.

A 20Hz servo-hydraulic fatigue test requires 1.5 years.

The 50Hz rotating bending testing machine will take 231 days.

The 300Hz high-frequency vibration table requires 38.5 days.

The 20KHz ultrasonic fatigue test only takes 13.8 hours.

【 Working Principle of Ultra-High Frequency Fatigue Testing Machine 】

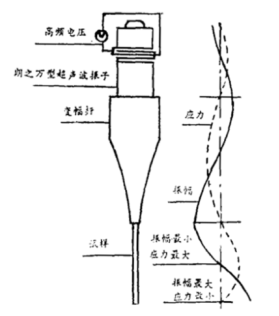

The longitudinal vibration generated by the Langevin-type 4-segment ultrasonic vibrator fixed by screws is amplified by the amplitude transformer to make the sample resonate. At this time, there are parts with extremely large amplitudes (vibration antinodes) and parts with extremely small amplitudes (vibration nodes) in the sample. The stress at the vibration nodes is the greatest, and fatigue damage is caused by the stress of longitudinal vibration and the inherent repetition times of the material. That is to say, at the center of the sample, there is the minimum displacement (displacement node) and the maximum strain (strain antinode).

Similarly, the maximum displacement (displacement inflection point) occurs at both ends of the specimen. In previous fatigue tests, the alternating strain had the same amplitude distribution along the entire length of the specimen, but at high frequencies, it varies from 0 at both ends of the specimen to the maximum value at the center along the length of the specimen. Therefore, one end of the specimen can be simply fixed to the amplitude variation rod by bonding or screwing.

This device is composed of the following parts: (1) Ultrasonic drive section, including ① ultrasonic vibrator; ② amplitude transformer; ③ high-speed optical displacement meter; (2) Electrical control section, including ① power unit; ② waveform observation unit; ③ measurement unit; ④ power supply unit.

Characteristics of the ultra-high cycle fatigue machine:

Compared with previous fatigue testing machines, this one has an extremely fast repetition cycle and the testing time required is extremely short.

2. No hydraulic operation is required. The testing machine is small in size, light in weight and easy to operate.

3. By using the selection components, various test aerosols can be selected. In addition, additional devices for tensile and compressive stress can also be equipped.

4. By measuring the resonance frequency of the sample, the Young's modulus can be determined;

5. Capable of measuring internal friction;

【 Application of Ultra-High Cycle Fatigue Test Machine】

Fatigue tests of new materials such as metals and ceramics that have been stretched and compressed to a certain extent;

2. Tensile-compressive fatigue test with overlapping external loads (stretching or compressing);

3. Three-point bending fatigue test;

4. Resonance-type fatigue crack propagation speed test;

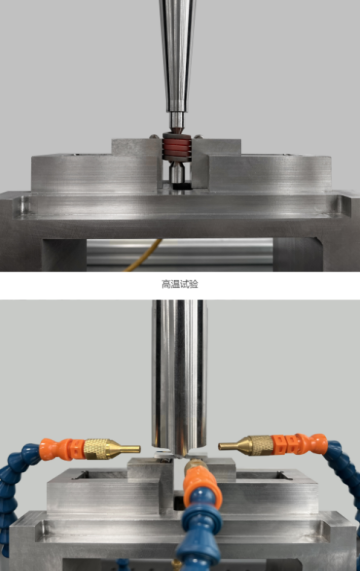

5. High-temperature fatigue test

6. Environmental fatigue test;

7.Measurement of internal friction during fatigue tests, etc.

The most significant feature of ultrasonic fatigue testing is the significant reduction in the time required for the fatigue test. For instance, conducting a 1010-cycle test at a frequency of 1Hz would take 320 years, but with a test at 20kHz, the test can be completed within 6 days. Thus, using ultrasonic testing enables conducting more experiments under different test conditions or repeating the same experiment within a given time frame, resulting in high-probability outcomes and conclusions. Moreover, for components subjected to high-frequency loads like turbine blades, when the test conditions are the same or similar to those used in actual operation (including frequency and stress), the testing machine is the most effective.

About 10 years ago, the United States also developed a similar testing machine to this newly developed one. However, it was said to be difficult to use. But using this newly developed testing machine to conduct fatigue tests on ceramic materials yielded very good results, which enabled us to obtain information about the material's changes during high repetitive cycle fatigue tests.