- Обзор

- Рекомендуемые продукты

- Процесс пайки прост и легок в освоении, значительно снижает расход припоя. В то же время уменьшает трудозатраты на производство и значительно повышает эффективность производства при одинаковых условиях;

- Значительно повышает электропроводность изделия, снижает сопротивление цепи, увеличивает площадь контактной поверхности и продлевает срок службы инструментальной головки для пайки;

- Не требует вспомогательного флюса или чистящего средства, снижает коррозию и предотвращает загрязнение воды и воздуха. Кроме того, не вызывает холодных паяных соединений или коротких замыканий;

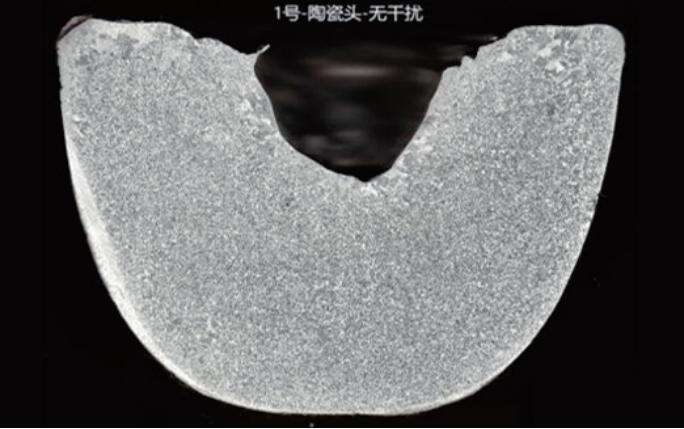

- При электронной микроскопии распределение размеров зерен в расплаве относительно равномерно, и эффект рафинирования расплава является значительным.

- 2. Размер зерен мал, поверхность ровная и без примесей, эффект очевиден, что доказывает возможность использования оборудования для металлического расплава для рафинирования зерен.

Обзор устройства :

Ультразвуковое оборудование для плавки металлов в основном используется для удаления примесей, пузырьков, измельчения зерен и улучшения качества отливок. Это чистая и относительно эффективная технология. Пористость является одним из основных дефектов алюминиевых отливок, поскольку она может ухудшать механические свойства и герметичность под давлением. Возникновение пористости в отливках обусловлено выделением газов из расплава во время затвердевания или тем, что жидкого металла недостаточно для компенсации объемной усадки через междендритные области. Поэтому эффективное удаление пузырьков является ключевым этапом в улучшении качества отливок.

20 кГц Ультразвуковое оборудование для плавки металлов (керамическая рабочая головка)

15 кГц Ультразвуковое оборудование для плавки металлов (титановая рабочая головка)

Принцип работы :

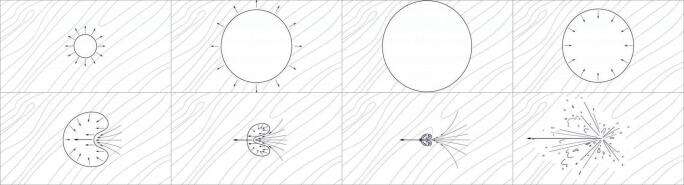

Тепловой эффект Ультразвуковое тепловое действие может создавать два вида теплового эффекта. Один из них – это тепловой эффект, создаваемый непрерывными волнами, а другой – мгновенный тепловой эффект. Сочетание этих двух эффектов усиливает внутреннее трение, в результате чего часть акустической энергии поглощается и преобразуется в тепловую энергию среды, способствуя повышению температуры жидкой среды и изменению вязкости и текучести раствора. Эффект акустического течения Когда ультразвуковая волна достигает определенной интенсивности, струйное течение, вызванное эффектом акустического течения, циркулирует по всему металлическому расплаву, образуя циркуляционный ток. Акустическое течение представляет собой комбинацию ламинарного и турбулентного взаимодействия, которое оказывает сильное вибрационное и перемешивающее воздействие на металлический расплав. Кавитационный эффект Кавитация – это физическое явление, вызванное ультразвуковыми волнами, и является основной причиной того, что ультразвуковые волны могут очищать металлические расплавы. При обработке жидкостей интенсивными ультразвуковыми волнами звуковые волны, распространяющиеся в жидкой среде, создают чередующиеся циклы высокого давления (сжатие) и низкого давления (разрежение). В цикле разрежения интенсивные ультразвуковые волны создают настоящие вакуумные пузырьки или полости в жидкости. Когда пузырьки достигают объема, при котором они больше не могут поглощать энергию, они резко схлопываются в цикле сжатия. Мелкие пузырьки создают давление до десятков тысяч атмосфер в момент схлопывания, оказывая сильное воздействие на окружающую жидкость и обеспечивая эффект перемешивания.

Иллюстрация кавитации

Преимущества оборудования:

Эксперимент демонстрирует :

Сравнение инструментальных головок из различных материалов

Инструментальная головка из высокопрочного титанового сплава, оснащенная ультразвуковым оборудованием для расплавленного материала, обладает повышенной коррозионной и термостойкостью, выдерживает температуру до 1300°C. Взаимодействие между микромолекулами расплава становится более прямым и выраженным. Кроме того, ее легко установить, не внося изменений в существующее производственное оборудование или технологический процесс клиента.

Керамическая головка

Во время ультразвукового литья металлических расплавов инструментальный стержень непосредственно контактирует с высокотемпературными металлическими расплавами, обеспечивая передачу ультразвуковых волн и реализацию ультразвуковой обработки металлических расплавов. Комбинированное воздействие высокотемпературной расплавной эрозии и термического напряжения в условиях высокотемпературного расплава быстро повреждает инструментальные стержни, изготовленные из обычных материалов. Керамические материалы обладают преимуществами устойчивости к высоким температурам, расплавной эрозии и износу, и уже применяются при выборе материалов для ультразвуковых инструментальных головок.

Головка инструмента из титанового сплава

Обработка расплавлением металла

Удаление примесей

Очень трудно, чтобы мелкие включения в жидкой стали всплывали, и только когда они собираются вместе, им становится легче всплывать. Используя оборудование для ультразвукового расплавления металла, чтобы ввести ультразвук в раствор, стоячая волна ультразвука может успешно расслаивать и концентрировать порошковые включения в растворе.

Удаление газов

Когда упругие вибрации ультразвука вводятся в расплавленный металл, возникает кавитация. Растворенные в жидком металле газы перемещаются в полости, способствуя образованию пузырькового ядра и его постоянному росту до тех пор, пока он не достигнет размера, при котором его можно удалить из расплавленного металла.

Измельчение зерна

В процессе непрерывной разливки алюминиево-кремниевого сплава ультразвуковая обработка может улучшить зернистость слитка, повышая пластическую деформируемость сплава для более эффективного применения в строительных материалах и поршнях автомобильных двигателей. Применение ультразвука к расплаву алюминиевого сплава позволяет избежать образования оксидных включений и улучшить его микроструктуру.

Повышение качества отливки

Воздействуя на кристаллизатор, улучшает качество поверхности отливаемого слитка. Может применяться для малых квадратных, крупных квадратных и слябовых заготовок без возникновения отрицательного скольжения во время ультразвуковой вибрации. После применения ультразвуковой вибрации к кристаллизатору при разливке малых и крупных квадратных заготовок достигается гладкая поверхность слитка.

Эксперимент по измельчению зерна :

Результаты эксперимента

Место проведения эксперимента