Physical and Chemical Properties:

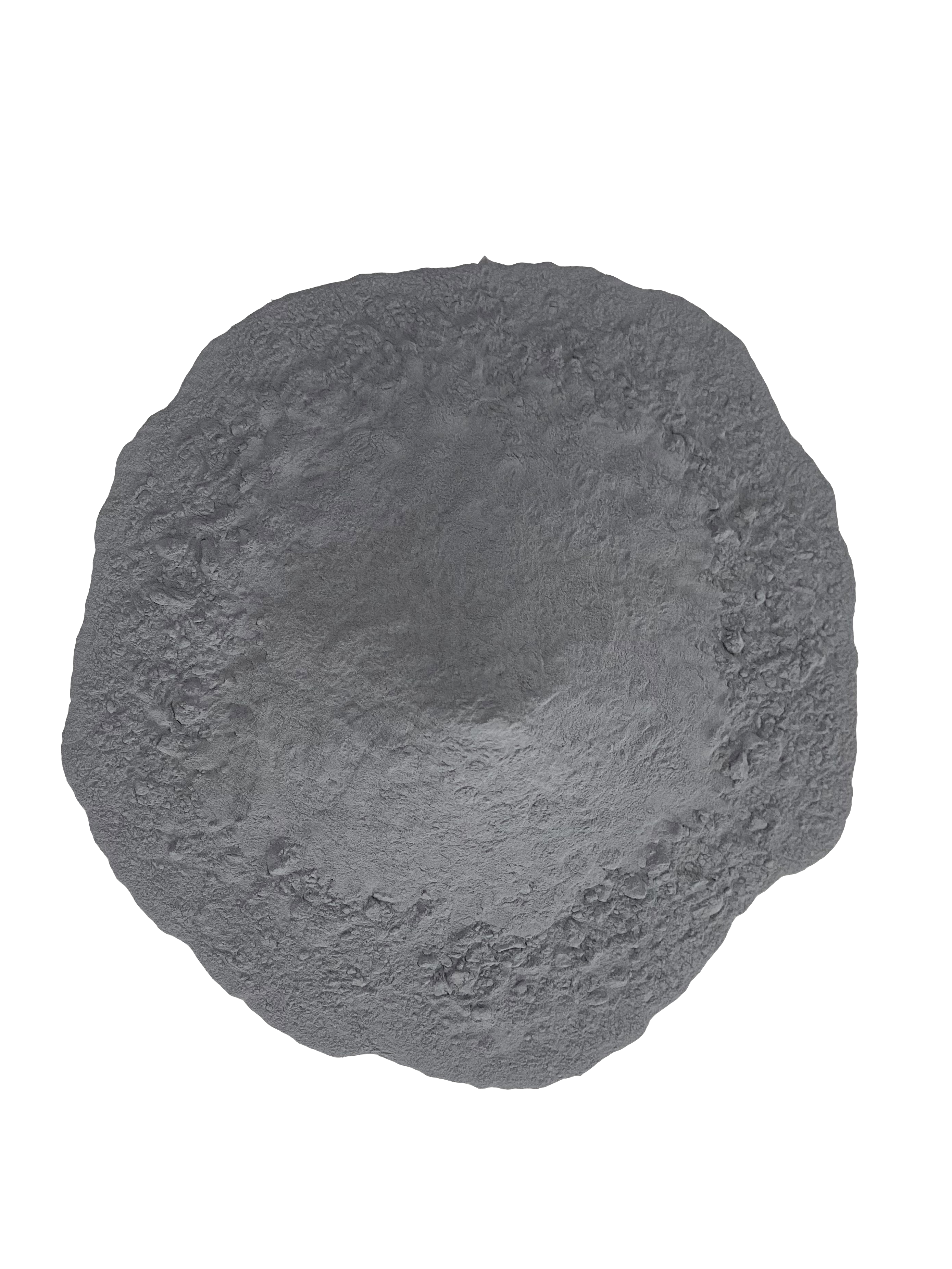

Melting Point: Approximately 156.6°C, with a low melting point. It is soft at room temperature and can be pressed into thin sheets.

Electrical and Thermal Conductivity: It has good electrical and thermal conductivity, second only to metals like silver, copper, and gold.

Chemical Activity: It is stable in air but easily reacts with acids, halogens, etc. It is not oxidized at room temperature but can react with oxygen at high temperatures to form indium oxide (In₂O₃).