Preparation Methods

Gas atomization method: The molten indium-based metal liquid is atomized by high-pressure gas, broken into fine droplets, and then rapidly cooled and solidified in the air to form powder. The powder prepared by this method has a relatively large particle size and irregular shape.

Centrifugal atomization method: The molten metal liquid is ejected by the centrifugal force of high-speed rotation to atomize into powder. The powder prepared by this method also has the problems of large average particle size and irregular shape.

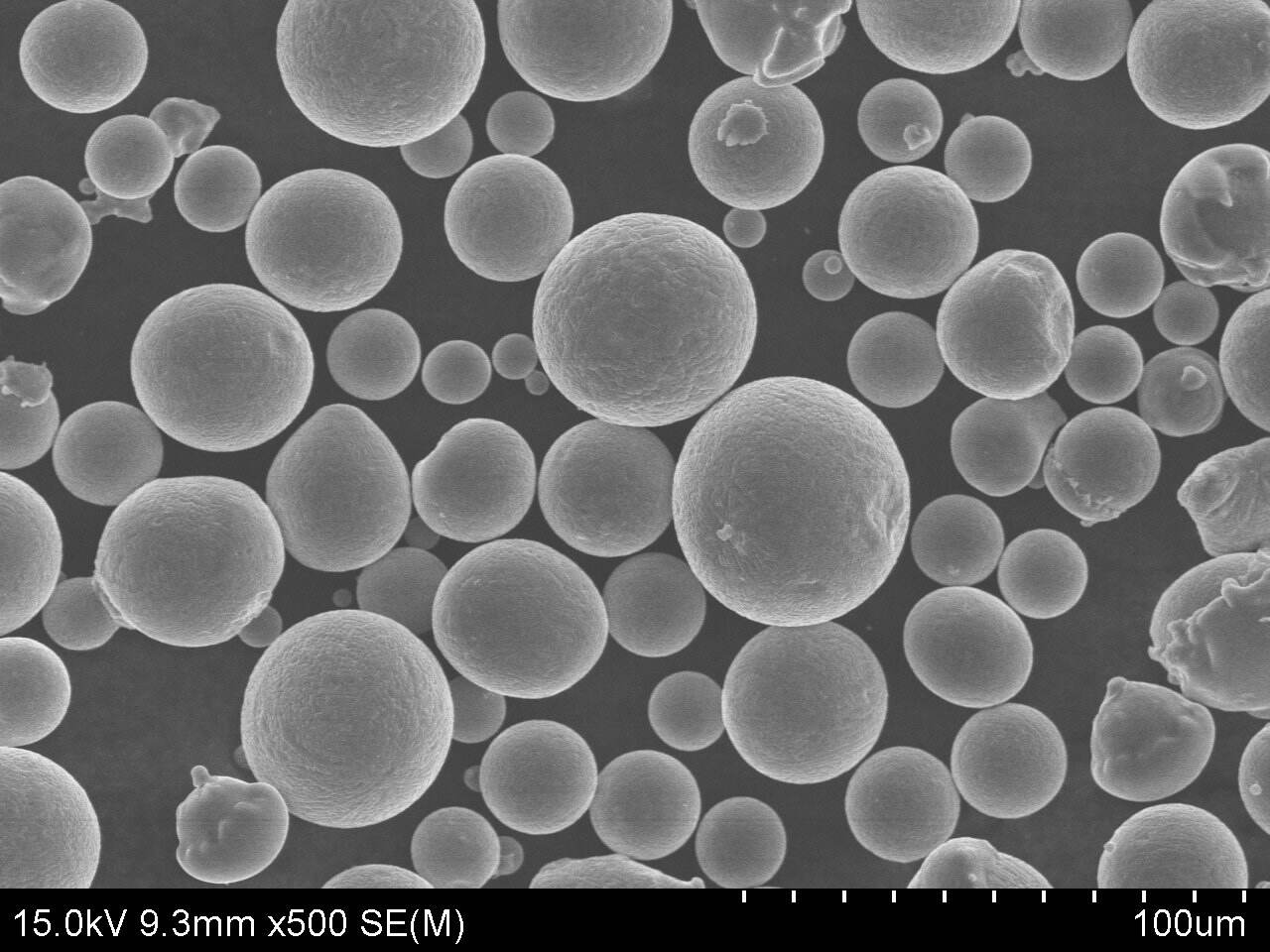

Ultrasonic atomization method: The molten indium-based metal liquid is broken into tiny droplets by the high-frequency vibration of ultrasonic waves, and then forms powder. Compared with the previous two methods, the powder prepared by ultrasonic atomization has better sphericity, which can effectively avoid the problem that a large number of small satellite powders adhere to the powder surface, and improve the quality and performance of the powder. Our company has adopted this manufacturing method.