Introduction

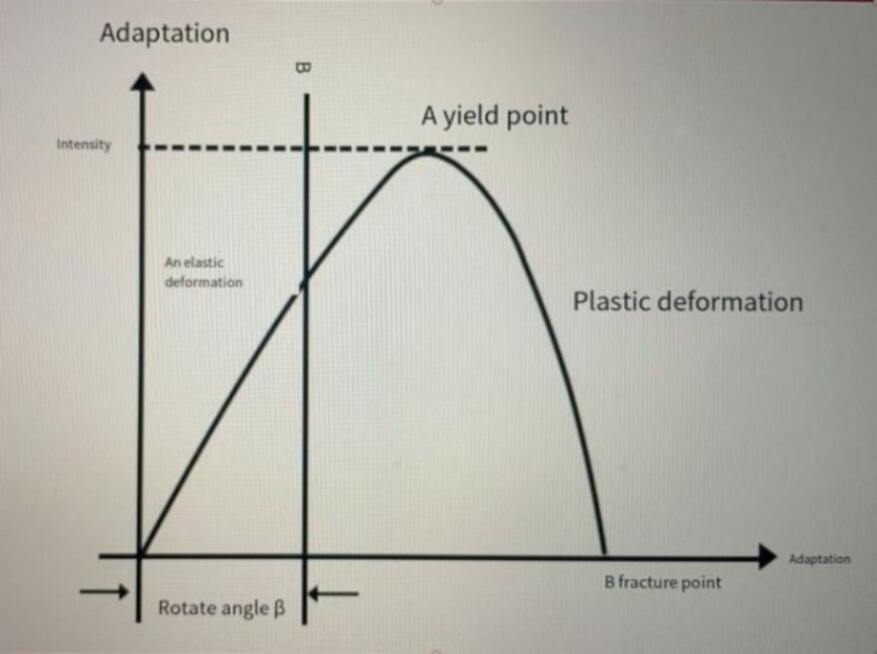

Yield strength is also called yield limit, and the stress at yield is called yield limit, with the unit of MPa. Yield strength is an inherent property of the material, indicating the critical stress value when the material yields. It is often used to determine the maximum allowable load of mechanical parts.

All mechanical parts are not allowed to undergo plastic deformation, so yield strength is an important basis for engineering design and material selection.

Yield

Yield refers to the phenomenon that strain increases without increasing stress. When the external force on a metal sample exceeds the elastic limit of the material, although the stress no longer increases, the sample still undergoes obvious plastic deformation.

Strength

Strength refers to the ability of a material to resist plastic deformation under external forces.

Elasticity

Elasticity refers to the ability to not produce permanent deformation. When the voltage of the ultrasonic generator changes, the output power of the generator also changes, making the mechanical vibration of the ultrasonic transducer unstable, resulting in poor working effect. Therefore, stable output power is required, and the amplifier is adjusted through the power feedback signal to stabilize the power amplifier. The transducer works most efficiently and stably at the resonant frequency. The resonant frequency of the transducer will change due to assembly or aging. If the frequency only drifts and does not change much, the frequency tracking signal can control the signal generator to maintain the frequency of the signal generator within a certain range of the resonant frequency of the transducer, allowing the generator to work in the best state.

The time required for a particle in the medium to vibrate back and forth once at the equilibrium position is called the period, which is represented by T and the unit is seconds (s);

The number of times a particle completes vibration within 1s is called the frequency, which is represented by f and the unit is "cycle/s", also known as Hertz (Hz).

The period and frequency are in a reciprocal relationship, as expressed by the following formula: f = 1 / T. The relationship between the wavelength (λ) of the sound wave in the medium and the frequency is: c = λf. Where c is the speed of sound, m/s; λ is the wavelength, and f is the frequency, Hz.

Elastic deformation

Material within the elastic limit deforms under the action of external force and returns to its original shape after the external force is removed. This deformation that disappears when the external force disappears is called elastic deformation.

Plastic deformation

When the load on the material exceeds the elastic deformation range, permanent deformation will occur. That is, the deformation that cannot be recovered after unloading is called plastic deformation.

The reasons for the deformation of the two are different:

Plastic deformation: There will be various defects in the atomic structure of the grain. Due to the existence of dislocations, the atoms of the crystal are easy to move along the dislocation line after the force is applied, reducing the deformation resistance of the crystal. Through the transmission of dislocation movement, slip causes part of the grain to slip to form a slip band, and many slip bands are combined to become visible deformation.

Elastic deformation: When an object is subjected to external force, it will deform. If the external force is removed, the object can completely restore its original shape and size.

Factors affecting plastic deformation

1. Work hardening: Plastic deformation causes dislocation proliferation, increased dislocation density, and intersection of dislocations in different directions. The movement of dislocations is hindered, causing the metal to work harden. Work hardening can increase the hardness, strength and deformation resistance of the metal, while reducing plasticity, making subsequent cold deformation difficult.

2. Internal stress: The distribution of plastic deformation in the metal body is uneven, so after the external force is removed, the elastic recovery of each part will not be exactly the same, which causes mutually balanced internal stresses between the parts of the metal body, namely residual stress. Residual stress reduces the dimensional stability of parts and increases the tendency of stress corrosion.

3. Anisotropy: After the metal is plastically deformed in the cold state, slip bands or twin bands appear inside the grains. Each grain also elongates and twists along the deformation direction. The strength, plasticity and toughness along the deformation direction are higher than those in the transverse direction. When the metal is deformed in a hot state, due to recrystallization, the orientation of the grains will deviate from the deformation direction to varying degrees.

4. Recrystallization and recovery: After recrystallization treatment, the grain distortion caused by cold deformation and the resulting work hardening, residual stress, etc. will be completely eliminated.

Elastic limit

The maximum stress at which a material does not produce permanent deformation (plastic deformation) is called the elastic limit. It is also the turning point of the material from the elastic range to plastic deformation. The elastic limit reflects the maximum range of elastic deformation of the material.

Tensile strength

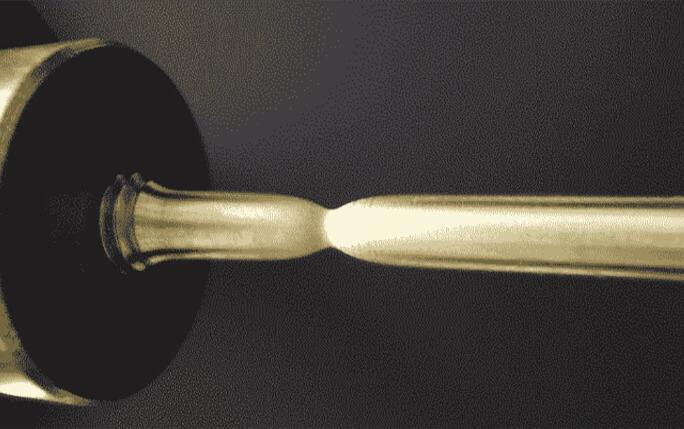

Under tensile conditions (after the material yields), the maximum stress that a specimen can withstand before breaking is called tensile strength, which is the critical value for the material to transition from uniform plastic deformation to local concentrated plastic deformation.

Tensile strength reflects the material's ability to resist fracture and damage. The greater the tensile strength, the greater the material's ability to resist fracture.

For parts with low deformation requirements, there is no need to rely on yield strength to control the deformation of the product. Tensile strength is usually used as the basis for design and material selection.

Plasticity

Plasticity refers to the ability of a material to withstand maximum plastic deformation before breaking. Elongation and area reduction are commonly used measurement indicators.

Expansion rate: δ=(L1-L)/L*100%

L 1: Gauge length after the specimen breaks.

L: Original gauge length of the specimen.

Area reduction: ψ=(AA1)/A*100%

A 1: Minimum cross-sectional area at the fracture of the specimen.

A: Original cross-sectional area.

The greater the elongation and area reduction, the better the plasticity of the material. Compared with the two, the reduction in area indicates that the plasticity is closer to the true strain because the contraction is independent of the length of the specimen.

Good plasticity is a necessary condition for the processing of metal materials. At the same time, the material has a certain degree of plasticity, which can also improve the reliability of machine parts and prevent sudden breakage of machine parts.