Introduction

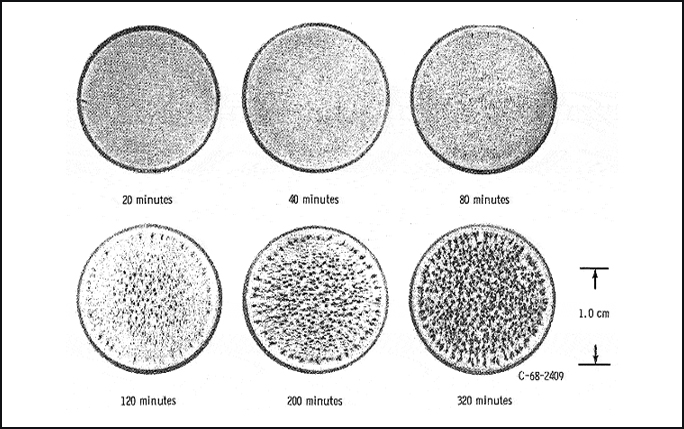

Cavitation erosion occurs when a material is exposed to a cavitating fluid. Collapsing cavitation bubbles cause strong shock waves and microjets that induce highly localized surface stresses. This repetition of loads due to repeated bubble collapse can lead to localized surface fatigue failure and subsequent shedding or spalling of material. The figure below shows a typical progression of cavitation erosion (25 kHz, 44.5µm, 24°C water).

In ultrasonics, cavitation is often actively generated by the ultrasonic horn in order to observe the effect on the process (e.g. ultrasonic homogenization). However, this cavitation gradually removes material from the horn surface, which can lead to some of the following problems.

1. As the tip shortens, the frequency of the system increases until the power supply can no longer activate the tool head.

2. When the corner face is pitted due to corrosion, it produces less cavitation, which affects the process.

3. The corroded material may contaminate the process.

These problems can be mitigated by a combination of the following four methods:

1. Use a material for the tool head with higher cavitation resistance.

2. Use a coating with higher cavitation resistance.

3. Improve the surface finish of the tool head.

4. Use a tool head with a replaceable tip.

Materials

Metal Products

For applications involving cavitation, titanium (usually Ti-6Al-4V) is often the default resonator material. It has acceptable (but not exceptional) resistance to cavitation and is also relatively inert to many liquids; various steels are also used. (See end of article for cavitation data for various materials).

Elastomers

Elastomers are not suitable as resonator materials. However, they can help prevent the transmission of ultrasonic energy or reduce cavitation erosion (primarily surface). Under relatively low intensity cavitation, these materials may be "completely free of cavitation damage". Cured ethylene propylene monomer (EPDM) sheet has three times the corrosion resistance of 316L stainless steel at 50µm peak vibration at 20 kHz. (Note: uncured EPDM coatings do not perform well).

Replaceable Replacement Caps

Replacing a solid horn after cavitation corrosion is costly. Instead, replaceable replacement caps are used on tool heads with end diameters less than Ø25mm.

Tool Head Coatings

Various coatings have been used to improve cavitation (compared to titanium as a reference). These coatings are applied to tool head faces when the tool head face area is too large or too small to use replaceable caps and when the face shape is irregular. They can also protect the base material of the tool head. Coatings can be classified by their thickness as thin or thick coatings. They can also be classified by toughness and brittleness.

Thin Coatings

If the inertial forces due to ultrasonic vibration are relatively low, the coating can be considered thin and adhesion does not have to be high. These coatings include chromium and titanium nitride.

Hard Chrome - A 2 mil (0.05 mm) hardness of chromium reduces cavitation by a factor of 10 compared to a 316L stainless steel base metal. This is attributed to the higher hardness of chromium (60 Rc vs. 25 Rc). Cavitation of stainless steel is largely dependent on the grain size of the material.

Titanium Nitride - Titanium nitride has long been used to reduce cavitation due to its hardness and good adhesion. However, the process cannot be applied indiscriminately. It is noteworthy that increasing the nitrogen atmosphere to around 13% (microhardness ≈ 550) leads to a steady reduction in cavitation. At this level, the erosion rate is 3 times lower than that of the original titanium. However, further increases in nitrogen and hardness do not reduce cavitation any further.

Thick coatings

Due to their mass, thick coatings have to resist enormous inertial forces. Insufficient adhesion between coating and substrate is a problem. If such coatings are also brittle, they cannot be applied over large areas (such as cleaning tanks) because ultrasonic bending can cause cracking of the coating.

Parameters Related to Cavitation

In relatively similar groups of materials, cavitation resistance generally increases with increasing mechanical properties, such as surface hardness, tensile strength, yield strength, ductility, strain energy, etc. However, large anomalies occur between different types of materials, such as ductile metals versus strong brittle metals, metals versus ceramics, metals versus elastomers, etc.

Hardness

Hardness is the primary material property associated with cavitation resistance. Base material hardness can be produced either globally (e.g. by hardening) or locally (e.g. by surface hardening or shot peening).

Shot Peening

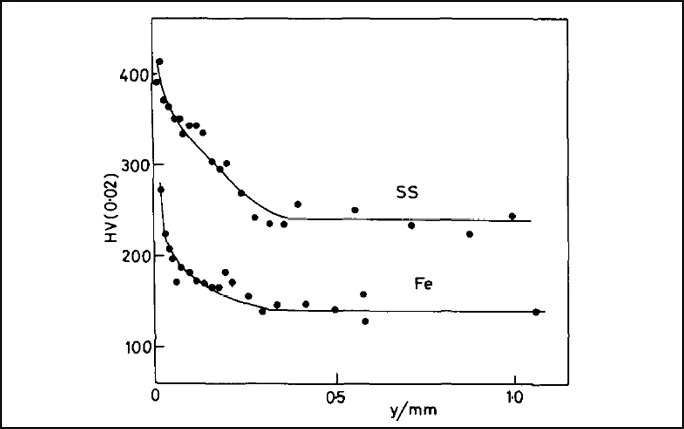

Shot peened 321 stainless steel (annealed) and pure iron were tested for cavitation at 20 kHz in distilled water and 1% brine. Shot peening hardened the material to a depth of 0.3 mm (321 grade stainless steel was chosen in part because it responds well to work hardening), with a specified amplitude of 15 μm (approximately peak value), and a water temperature of 50°C. (In Figure 3, "y" is the distance [mm] below the specimen surface, and the vertical axis is labeled "HV 0.02").

Surface Finish

When a material is initially subjected to cavitation, there may be an initial phase during which the corrosion rate is negligible compared to subsequent phases. This initial phase can be extended if the surface is highly polished.

Grain Size

Like fatigue, cavitation occurs on a microscopic scale. Therefore, two materials with nearly identical macroscopic properties (e.g., tensile strength) may have significantly different resistance to cavitation. The fact that the cavitation resistance of the same material increases with decreasing grain size does not make sense for a different material.

Cavitation data for various materials

The following information is provided for reference. Many of the listed materials may not be suitable for use as ultrasonic tool tips due to losses, fatigue, cost, and material availability. For example, although many steels have lower corrosion rates than titanium, their output amplitude is limited by internal losses (heating). However, this heating issue can be improved by optimizing profiles that reduce local ultrasonic stresses. In any case, some materials may still be suitable for use as replaceable replacement caps or coatings.

Test Environment

1. The cavitating fluid was room temperature water.

2. The amplitude was 50 microns peak-to-peak.

3. The tip diameter was 13.9 mm.

4. MDP = Mean Depth of Penetration [mils] = (Volume Loss)/(Specimen Surface Area).

5. 1 mil = 25.4 microns.

Cavitation rate of various materials

| Test Materials | MDP average rate (Mils/h) |

|---|---|

| MDP average rate (Mils/h) | 0.02 |

| T-111 Tantalum alloy | 0.06 |

| Mo-½Ti | 0.09 |

| 316 SS | 0.09 |

| 304 SS | 0.10 |

| Cb-1Zr | 0.15 |

| Cb-1Zr, annealed | 0.18 |

| Carbon steel (mild) | 0.23 |

| Cu-Zn, cold-worked | 0.38 |

| Ni, cold-worked | 0.44 |

| Cu-Ni, 1800°F anneal | 0.47 |

| Ni, 1600°F anneal | 0.48 |

| 2024-T351 Aluminum | 0.57 |

| Ni, 1100°F anneal | 0.58 |

| Cu-Ni, 1300°F anneal | 0.63 |

| Cu-Zn, 1400°F anneal | 0.68 |

| Cu-Ni, cold-worked | 0.70 |

| Cu-Zn, 850°F anneal | 0.72 |

| 6061-T651 Aluminum | 0.72 |

| Cu, cold-worked | 0.95 |

| Cu, 1500°F anneal | 0.95 |

| Cu, 900°F anneal | 1.02 |

| Plexiglas | 1.39 |

| 1100-0 Aluminum | 2.70 |

Titanium

Ti-6Al-4VWhen operated at maximum amplitude, a 1 mm ultrasonic tool tip will corrode in 1000 hours.

Stainless Steel

In cavitation testing of twelve stainless steels in water, it was found that the best cavitation resistance occurs when the chromium to nickel content ratio is approximately 1.8:1.