The principle of both

Laser Cutting Principle

Laser cutting is one of the thermal cutting methods. The principle of laser cutting is to use a focused high-power density laser beam to irradiate the workpiece, causing the irradiated material to quickly melt, vaporize, ablate or reach the ignition point, and at the same time use a high-speed airflow coaxial with the beam to blow away the molten material, thereby achieving cutting of the workpiece.

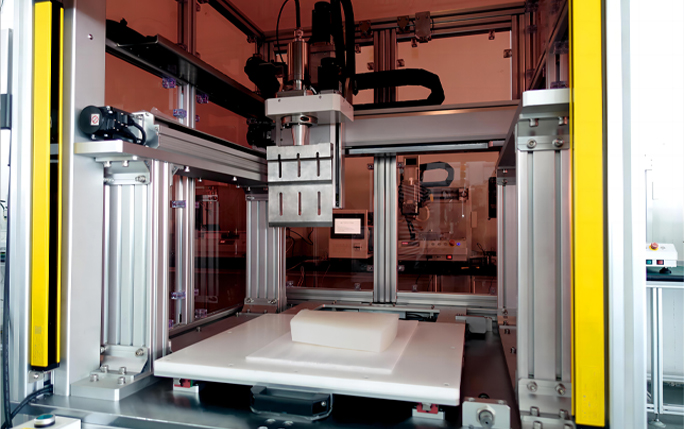

Ultrasonic cutting principle

The principle of ultrasonic cutting is to transfer the ultrasonic energy generated by the ultrasonic transducer to the horn, which then amplifies the energy and transmits it to the cutting blade to drive the cutting blade to vibrate at a high frequency. Under the action of the huge ultrasonic energy, the cutting position softens and melts instantly, and the strength is greatly reduced. Only a small amount of force is required to achieve the purpose of cutting the material.

Advantages

Laser cutting

As a new processing method, laser processing has been widely used in the leather, textile and clothing industries for its advantages of precise and fast processing, simple operation and high degree of automation. Compared with traditional cutting methods, laser cutting machines are not only inexpensive and low in consumption, but also because laser processing has no mechanical pressure on the workpiece, the effect, accuracy and cutting speed of the cutting products are very good. It also has the characteristics of operational safety, maintainability, simplicity, etc., and can work 24 hours a day. The dust-free cloth non-woven fabric cut by the laser laser machine is automatically sealed without loosening, deformation, or hardening, and the size and accuracy are consistent; it can cut any complex shape with high efficiency and low cost.

Ultrasonic cutting

Ultrasonic cutting has the advantages of smooth and firm incision, accurate cutting, no deformation, no warping, no linting, and no wrinkling. It can avoid the shortcomings of "laser cutting machine" such as rough cutting, burnt edge, and pilling, but at present, ultrasonic cutting machine is more difficult than laser cutting machine in automation, so the efficiency of laser cutting is higher than that of ultrasonic cutting.

Application fields

Laser cutting

1. Automobile manufacturing

In the field of automobile manufacturing, laser cutting machines are mainly used for the manufacture of parts such as car bodies, frames and wheels. The high-precision cutting of laser cutting machines can improve the quality and production efficiency of parts. At the same time, laser cutting machines can also cut metal sheets quickly and accurately to meet the needs of automobile manufacturing.

2. Machinery manufacturing

In the field of machinery manufacturing, laser cutting machines can be used for the manufacture of various precision parts. Laser cutting machines have the characteristics of high speed and high precision, which can greatly improve production efficiency. At the same time, laser cutting machines can also cut various metal materials to meet the needs of machinery manufacturing.

3. Electronics industry

In the electronics industry, laser cutting machines are mainly used for the manufacture of circuit boards and electronic components. The high precision and high speed of laser cutting machines can ensure the quality and consistency of circuit boards and electronic components. At the same time, laser cutting machines can also process various high-precision electronic components to meet the production needs of the electronics industry.

4. Petrochemicals

In the field of petrochemicals, laser cutting machines can be used for the manufacture and maintenance of pipes and containers. Through the precise cutting of laser cutting machines, material waste can be reduced and production efficiency can be improved. At the same time, laser cutting machines can also cut high-temperature, high-pressure and highly corrosive materials to meet the production needs of petrochemicals.

5. Aerospace

In the field of aerospace, laser cutting machines can be used in the manufacture of spacecraft such as aircraft and rockets. Due to the characteristics of high strength and high hardness of aerospace materials, high precision and stability requirements are required for laser cutting machines. At the same time, laser cutting machines can also cut high-temperature, high-pressure and high-vacuum materials to meet the production needs of aerospace.

Ultrasonic cutting

Ultrasonic cutting technology relies on high-frequency vibration to reduce cutting force, reduce heat generation and improve processing accuracy. It is widely used in the processing of carbon fiber composite materials, honeycomb structures and high-strength aviation materials. Its advantages include reducing burrs and delamination, improving surface quality, and extending tool life. This technology is suitable for aerospace, automotive and industrial manufacturing, especially in complex geometric shapes and high-precision cutting, effectively improving the efficiency and quality of material processing.