Brief introduction of manufacturing process

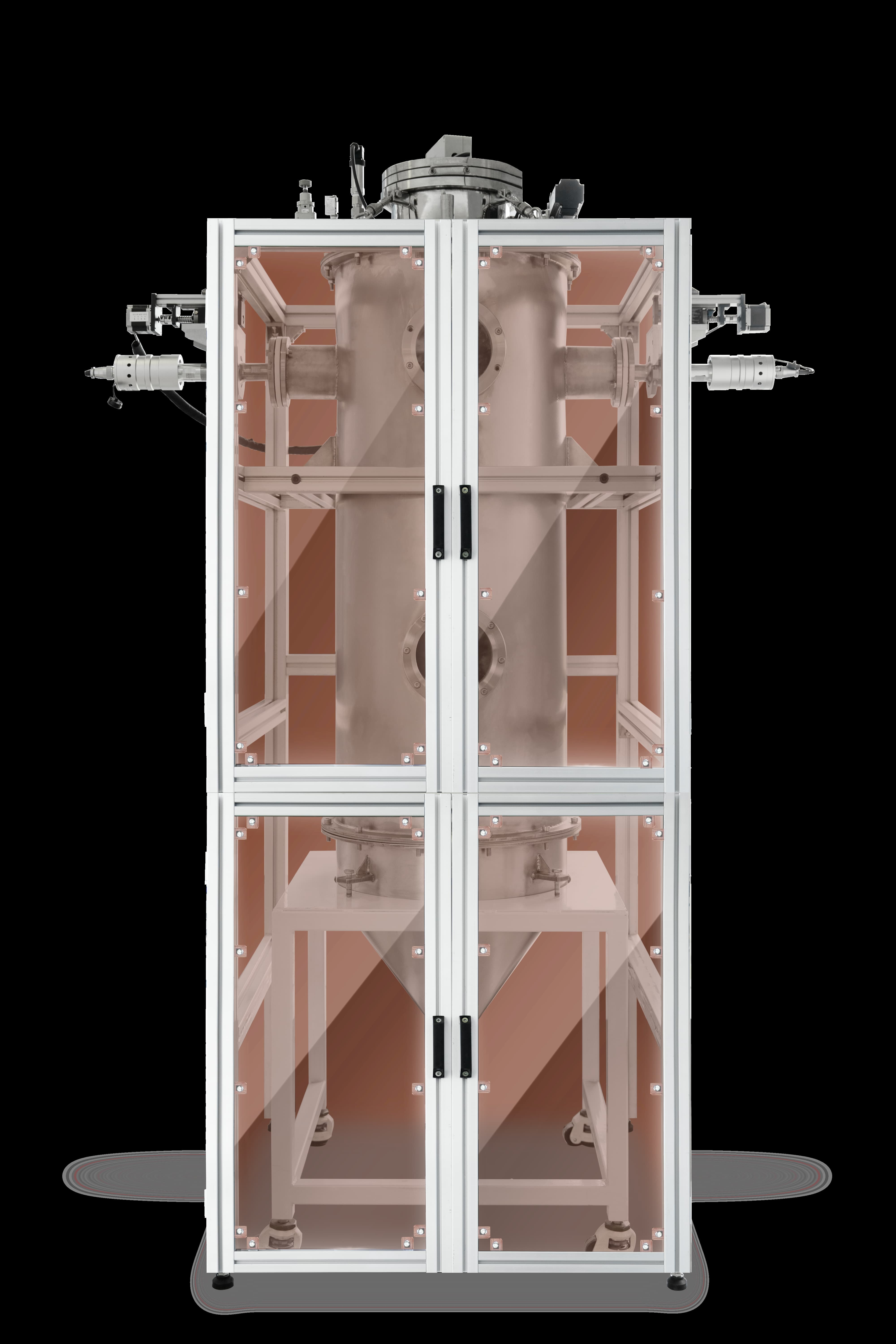

The ultrasonic metal powdering technology process involves heating the required powder material to a liquid state in the front-end melting module. This liquid is then introduced into the mid-stage ultrasonic atomization surface. Simultaneously, an ultrasonic generator produces high-frequency electromagnetic energy, which is converted into high-frequency mechanical energy via an ultrasonic transducer, resulting in longitudinal high-frequency vibration. The output end of the transducer is connected to an amplitude booster, which amplifies the vibration and transmits it to the atomization surface, generating a standing wave. As the molten metal liquid passes through the atomization surface, it is fragmented into uniform micron-sized droplets under the influence of the high-frequency vibration and standing wave. In an inert gas protection preparation environment, these droplets rapidly cool and solidify, forming micron-sized metal solid particles. These solidified metal particles fall into the powder collection cylinder and are collected to become the desired metal powder.