A precisão aumentada nos ensaios não destrutivos com Transdutor Ultrassônico TECNOLOGIA

Como as ondas ultrassônicas detectam falhas sem danificar materiais

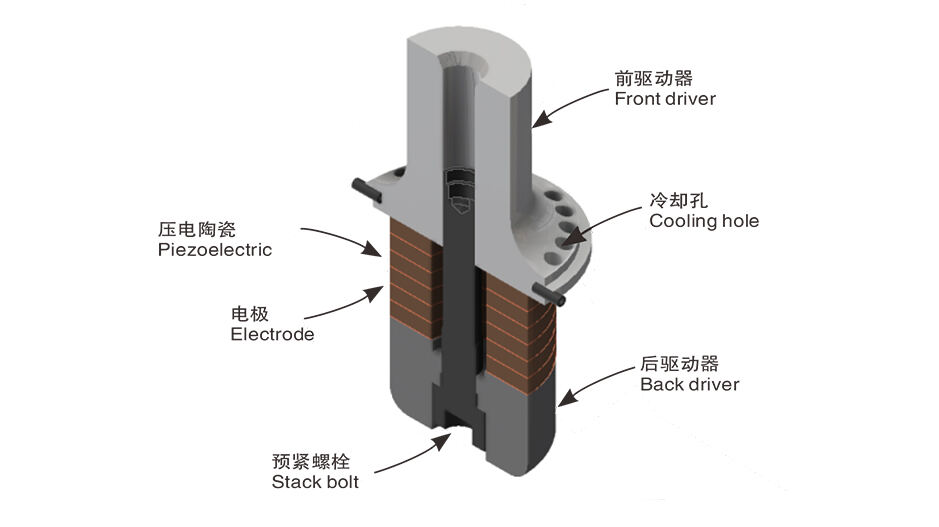

Os transdutores ultrasónicos são muito úteis para o que chamamos de testes não destrutivos, basicamente disparam ondas sonoras de alta frequência através de materiais sólidos. As ondas continuam a avançar em linha reta até atingirem algo estranho como uma rachadura ou espaço vazio dentro do material. Quando isso acontece, parte da onda rebota de volta para onde veio. Estes ecos de retorno são captados por partes especiais no transdutor conhecidos como elementos piezoelétricos que transformam essas vibrações mecânicas em sinais elétricos reais que podemos ler. Os técnicos olham para quando estes ecos voltam e quão fortes são para descobrir exatamente onde os problemas estão escondidos no interior dos materiais, às vezes com precisão de milímetros. A melhor parte? Não é preciso tocar no material, cortar amostras ou lidar com radiação prejudicial. Tudo fica intacto, mas ainda temos uma visão super detalhada do que se passa lá dentro.

Métodos-chave: difração do tempo de voo e eco de pulso na TNC

Dois métodos primários dominam a detecção de falhas:

- Difração do tempo de voo (TOFD) medir padrões de difração de ondas em torno de pontas de rachadura

- Ecossonografia calcula distâncias usando intervalos de retorno de eco

O TOFD se destaca no dimensionamento de defeitos em estruturas de paredes grossas, como vasos de pressão, enquanto os sistemas Pulse-Echo fornecem medições de espessura em tempo real com precisão de ± 0,1 mm. Ambas as técnicas utilizam transdutores ultrasônicos como transmissores e receptores de duplo propósito, eliminando a necessidade de mudanças de equipamento durante a inspeção e reduzindo o tempo de inatividade industrial.

Aplicação no mundo real: Identificação de micro-fissuras em componentes aeroespaciais

A detecção de pequenas micro-fissuras menores de meio milímetro é absolutamente essencial para as pás de turbina de aviões. Para conseguir isso, os transdutores ultrasônicos trabalham em frequências tão altas quanto 20 MHz, o que lhes dá uma melhor resolução. Também usam feixes angulares para entrar em locais difíceis e executam um software especial de imagem que pode detectar essas fraturas de esforço quase instantaneamente. De acordo com uma pesquisa publicada no ano passado em revistas de aviação, esses métodos detectaram rachaduras de fadiga em peças de liga de níquel com cerca de 97% de precisão. Isso significa que dos 4.200 motores que verificaram, a maioria dos potenciais desastres foram detectados antes da decolagem. Dado o que sabemos agora dessas descobertas, não é surpresa que as autoridades de segurança tenham começado a exigir testes não destrutivos para cada peça de equipamento considerada vital para as operações de voo.

Uso crescente de matrizes de transdutores ultrasônicos em testes industriais

Cerca de 58% das novas instalações industriais usam agora sistemas de matriz em fase em vez dos antigos transdutores de elemento único. Os vários elementos nessas matrizes permitem dirigir feixes eletronicamente sem componentes mecânicos, cobrir superfícies complicadas durante a varredura e obter imagens 3D detalhadas de falhas quase instantaneamente. Para as pessoas que trabalham no campo da energia, esta tecnologia reduz o tempo de inspecção de tubulações em cerca de 35%, o que faz uma grande diferença quando se lida com grandes projetos de infraestrutura. À medida que esses sistemas se tornam mais adaptáveis e os preços caem, muitos fabricantes esperam ver sua produção de transdutores de matriz especializados saltar cerca de 40% até 2027. Esta tendência está definitivamente a acelerar à medida que as empresas as adotam em várias aplicações da Indústria 4.0, onde a precisão é mais importante.

Melhoria da manutenção preditiva através de monitoramento baseado em ultrassom

Detecção precoce de problemas de desgaste e lubrificação de rolamentos

Os transdutores de ultra-som são muito bons em detectar problemas com rolamentos muito antes de se tornarem problemas sérios. Funcionam captando os sons de alta frequência que vêm das máquinas. Quando o lubrificante começa a quebrar, há mais atrito a acontecer lá dentro, o que cria ondas ultra-sônicas acima de 20 kHz que podemos medir. O que torna isto interessante é que estes padrões sonoros mostram quando as partes metálicas começam a tocar umas às outras semanas antes do tempo em comparação com verificações de vibração regulares. A capacidade de detectar estes sinais cedo significa que as empresas não têm de substituir rolamentos com tanta frequência. Alguns estudos sugerem que essa abordagem reduz os custos de substituição em cerca de 35 a 40 por cento em comparação com esperar até que algo se quebre completamente.

Monitoramento em tempo real da saúde dos equipamentos através da análise das emissões acústicas

A monitorização acústica contínua converte as emissões ultrasônicas em métricas de saúde quantificáveis. Algoritmos avançados analisam assinaturas de alta frequência para identificar problemas sutis como micro-pitting em engrenagens ou turbulência em fluxos hidráulicos. Ao contrário das inspecções manuais periódicas, o processamento em tempo real fornece informações diagnósticas ininterruptas, permitindo que a manutenção seja programada dinamicamente sem interromper a produção.

Exemplo de caso: Redução do tempo de inatividade na fabricação com sensores ultrasônicos

Um grande fabricante de peças de automóveis instalou recentemente sensores ultrasônicos permanentes em suas 47 estações de solda robóticas para manter um olho nos irritantes atuadores pneumáticos. A equipa técnica descobriu que quando combinaram os sinais de ultra-som provenientes de pistões com vazamentos de pressão regulares, podiam detectar problemas de vedação muito antes de se tornarem grandes problemas durante os períodos de manutenção de rotina. Ao longo de dois anos, esse monitoramento proativo reduziu as falhas inesperadas de equipamentos em quase 30 por cento. Isso traduz-se em poupar cerca de 1.200 horas de produção por ano, apenas por detectar problemas cedo. Além disso, houve outro bónus: o consumo de energia dos compressores de ar caiu cerca de 15%, o que é bastante impressionante quando se olha para os custos operacionais a longo prazo.

Integração de sensores ultra-sônicos inteligentes nos sistemas da Indústria 4.0

Os sensores ultra-sônicos hoje trabalham com padrões IIoT como MQTT para enviar informações diretamente para sistemas de manutenção preditiva. O sistema toma esses padrões de vibração e características de fluxo e transforma-os em gráficos FFT que os operadores podem realmente ler. Enquanto isso, as ferramentas de computação em nuvem analisam como as diferentes máquinas funcionam juntas ao longo do tempo. Quando algo dá errado, o sistema de monitorização central envia avisos para a equipe de manutenção sobre problemas reais em vez de todos aqueles irritantes falsos positivos que vemos com tanta frequência em grandes fábricas. Esta abordagem economiza tempo e dinheiro, porque os técnicos sabem exatamente onde concentrar seus esforços quando surgem problemas em linhas de produção com dezenas ou mesmo centenas de dispositivos conectados.

Detecção e medição de distâncias de obstáculos fiáveis em ambientes industriais adversos

Por que os transdutores de ultrassom superam os sensores ópticos em condições difíceis

Os transdutores ultra-sônicos funcionam muito bem em locais onde os sensores ópticos simplesmente não funcionam, especialmente quando há muita poeira a flutuar, nevoeiro espesso ou iluminação que muda constantemente. A diferença entre estes e sistemas de infravermelhos ou luz visível é bastante grande. Os outros sistemas tendem a ficar confusos quando as partículas estão por todo o lado, mas os ultra-sônicos emitem ondas sonoras de alta frequência que não se importam com o que está a bloquear a visão. Algumas pesquisas sobre robótica também revelaram algo interessante. Em condições de poeira, estes sensores ultra-sônicos captaram obstáculos cerca de 98% do tempo, enquanto os sistemas ópticos só conseguiram cerca de 72%. Faz sentido por que tantas empresas em operações de mineração, em canteiros de obras e grandes fábricas confiam neles para seus equipamentos. Continuam a trabalhar, não importa o que lhes seja lançado.

Princípios de variação baseados em eco e vantagens industriais

Os transdutores de ultra-som calculam distâncias medindo quanto tempo leva a onda sonora para se rebater depois de ser emitida. Basicamente, eles registam o intervalo entre quando enviam um pulso e quando recebem o eco de volta. O que torna esta abordagem tão boa é que ela ainda pode ser precisa até o nível do milímetro, mesmo quando se trata de superfícies complicadas ou materiais refletores. Tomemos sistemas a laser, por exemplo, estes precisam de ajustes e recalibrações constantes ao longo do tempo. Os sensores ultra-sônicos continuam a funcionar de forma fiável sem muita confusão. Essa confiabilidade significa que eles lidam muito bem com condições adversas, quer se trate de áreas de armazenamento de frio congeladas ou máquinas que vibram constantemente durante toda a operação.

Spotlight de aplicação: Navegação AGV usando sensores ultrasônicos

Armazéns e fábricas estão agora se voltando para veículos guiados por máquinas (AGVs) que usam transdutores de ultrassom para se movimentarem com segurança. Estes veículos têm sensores de dupla frequência que lhes permitem distinguir entre coisas fixas como paredes e coisas em movimento como empilhadeiras ou trabalhadores que passam. Os números também confirmam isto. Um olhar para as estatísticas de automação logística do ano passado mostra que os locais que implementaram estes sistemas de ultra-som viram os seus problemas de colisão diminuírem em cerca de 40%. Isso significa menos acidentes e menos tempo perdido quando as máquinas param de funcionar porque algo se interpôs no caminho.

Aumentar a eficiência no controlo do processo de produção através da detecção por ultra-som

Os transdutores ultrasônicos otimizam a produção industrial através de monitoramento sem contato, permitindo ajustes em tempo real, minimizando os riscos de contaminação. A sua durabilidade em condições adversas permite a otimização contínua dos processos em sectores críticos.

Monitoramento dos níveis e dos caudais de fluidos em tempo real

Os sensores ultrasônicos fornecem medição instantânea e sem contato dos níveis e taxas de fluxo de fluidos, eliminando os riscos de contaminação associados a sondas invasivas. No transporte de produtos químicos perigosos e no processamento farmacêutico, a retroalimentação acústica contínua garante um controlo preciso do inventário e reduz os derrames. Os estudos mostram que a monitorização sem contacto reduz os resíduos de materiais em 812% em aplicações de manuseio de líquidos.

Métodos Doppler e de tempo de trânsito para medição precisa do caudal

Os medidores de fluxo ultrasônicos usam duas técnicas primárias dependendo das propriedades do fluido:

| Método | Princípio de funcionamento | Precisão | Aplicações ideais |

|---|---|---|---|

| Doppler | Mudança de frequência de partículas em movimento | ±2–5% | Laminhas, águas residuais |

| Tempo de trânsito | Duração do percurso do pulso diferencial | ±0.5–1% | Produtos farmacêuticos, solventes |

Ambos os métodos operam sem obstruir o fluxo, evitando quedas de pressão e desgaste mecânico comuns em sistemas baseados em turbinas. O Doppler é eficaz em fluidos opacos ou carregados de partículas, enquanto o tempo de trânsito é preferido para aplicações de alta pureza que exigem precisão.

Otimização dos sistemas de dosagem química com feedback do transdutor ultrasônico

Em sistemas de dosagem de circuito fechado, os transdutores ultrasónicos ajudam a controlar como os aditivos são injetados nos processos, respondendo ao que está a acontecer agora com níveis de concentração e taxas de fluxo. Quando há alterações detectadas no processo, as válvulas proporcionais podem ajustar a dose em apenas 50 milissegundos, mantendo a precisão dentro de mais ou menos 0,3 por cento na maioria das vezes. O sistema pára automaticamente de alimentar quando a viscosidade começa a agir, o que reduz o uso de produtos químicos entre 5% e 15%. Isto não só economiza dinheiro ao longo do tempo, mas também garante que as operações permaneçam dentro daquelas regras ambientais complicadas que todos têm de seguir hoje em dia.

Soluções de transdutor ultrasônico de baixo custo e baixa manutenção para fabricação escalável

Os fabricantes de várias indústrias estão constantemente sob pressão para aumentar as suas capacidades de produção sem quebrar o banco. Os sistemas de transdutor ultrasônico surgiram como uma mudança de jogo para muitas empresas que procuram cortar despesas. Estes sistemas costam geralmente cerca de 30 a 40 por cento menos em comparação com os sensores mecânicos tradicionais. De acordo com uma pesquisa publicada pela Ponemon em 2023, algumas fábricas viram seus custos anuais de manutenção cair de cinquenta mil a cem mil dólares por linha de montagem, uma vez que mudaram para a tecnologia ultrasônica. Este tipo de poupança é muito importante quando se tenta equilibrar o controlo da qualidade com as restrições orçamentais.

Menor custo total de propriedade em comparação com sensores mecânicos e ópticos

Os sensores mecânicos precisam de uma recalibração regular, enquanto os ópticos ficam perturbados pelo acúmulo de poeira. Os transdutores ultrasónicos funcionam de forma diferente, uma vez que não tocam em nada e não têm absolutamente nenhum componente móvel. A falta de contacto físico significa que não há desgaste com o tempo, por isso as fábricas não têm de se preocupar com ajustes constantes. Isto é muito importante quando se executam operações de grande escala, onde o tempo de inatividade custa dinheiro. O interessante é que estes dispositivos correspondem à precisão dos sensores ópticos mesmo quando lidam com condições de poeira contendo cerca de 1.000 ppm de partículas. Além disso, os fabricantes acharão que são mais baratos de produzir em comparação com seus homólogos ópticos.

Menor necessidade de manutenção e maior vida útil

A caixa selada mantém os transdutores ultra-sônicos seguros de condições adversas como temperaturas que vão de -40 graus Celsius até 85 graus Celsius, além de proteger contra umidade e produtos químicos sem qualquer queda no desempenho. Os relatórios de campo mostram que estas unidades duram cerca de três vezes mais tempo entre os serviços em comparação com os sensores mecânicos tradicionais. O tempo médio entre falhas ultrapassa 100 mil horas quando funcionam continuamente, o que é bastante impressionante. Quando a manutenção é necessária, é normalmente uma limpeza rápida do diafragma. Não é necessário substituir peças com tanta frequência como as opções eletromecânicas, economizando tempo e dinheiro a longo prazo.

Estudo de caso ROI: Implementação de sensores ultrasônicos em linhas de montagem automotiva

Uma fábrica de automóveis atualizou 85 de suas estações de trabalho robóticas com sensores ultrassônicos de série em fases para verificar as peças enquanto elas estavam sendo feitas. A empresa recuperou o dinheiro em pouco mais de um ano porque 47% menos peças estragadas foram jogadas fora, além das paralisações de produção de 720 dólares por hora quando os sensores precisavam ser ajustados. Os técnicos passaram muito menos tempo a consertar estes sensores agora que os requisitos de manutenção tinham caído cerca de três quartos. Isto libertou a sua agenda para que pudessem trabalhar para melhorar o funcionamento do sistema em vez de apagar incêndios com equipamentos avariados.

Perguntas Frequentes

O que é um teste não destrutivo por ultra-som?

Os testes não destrutivos por ultra-som utilizam ondas sonoras de alta frequência para detectar imperfeições internas dentro dos materiais sem causar qualquer dano.

Como os transdutores de ultrassom ajudam na manutenção preditiva?

Os transdutores de ultra-som detectam sinais precoces de desgaste e problemas de lubrificação do equipamento analisando padrões sonoros de alta frequência, permitindo uma manutenção proativa.

Por que os transdutores de ultrassom são preferidos aos sensores ópticos em ambientes empoeirados?

Os transdutores de ultra-som enviam ondas sonoras que não são afetadas por poeira ou partículas, tornando-os mais confiáveis do que os sensores ópticos em tais condições.

Que benefícios em termos de custos oferecem os transdutores de ultrassom aos fabricantes?

Reduzem os custos de manutenção e os tempos de inatividade, com uma economia que varia de 30% a 40% em comparação com os sensores mecânicos ou ópticos.

Sumário

- A precisão aumentada nos ensaios não destrutivos com Transdutor Ultrassônico TECNOLOGIA

-

Melhoria da manutenção preditiva através de monitoramento baseado em ultrassom

- Detecção precoce de problemas de desgaste e lubrificação de rolamentos

- Monitoramento em tempo real da saúde dos equipamentos através da análise das emissões acústicas

- Exemplo de caso: Redução do tempo de inatividade na fabricação com sensores ultrasônicos

- Integração de sensores ultra-sônicos inteligentes nos sistemas da Indústria 4.0

- Detecção e medição de distâncias de obstáculos fiáveis em ambientes industriais adversos

- Aumentar a eficiência no controlo do processo de produção através da detecção por ultra-som

- Soluções de transdutor ultrasônico de baixo custo e baixa manutenção para fabricação escalável

-

Perguntas Frequentes

- O que é um teste não destrutivo por ultra-som?

- Como os transdutores de ultrassom ajudam na manutenção preditiva?

- Por que os transdutores de ultrassom são preferidos aos sensores ópticos em ambientes empoeirados?

- Que benefícios em termos de custos oferecem os transdutores de ultrassom aos fabricantes?