Introduction to Ultrasonic Atomization Spraying

Ultrasonic atomization spray equipment is widely used in industry and research and development. Due to environmental factors and excessive pollution, scientists, engineers and designers use ultrasonic atomization spray equipment, which will replace traditional two-fluid spraying as a more precise, easier to control and more environmentally friendly spraying technology. Ultrasonic spray equipment, with its gentle spray characteristics, greatly reduces overspraying, thereby reducing costs and pollution to the surrounding air. At the same time, this new technology has also expanded more application areas, such as spraying at low flow rates is ideal. In addition, because ultrasonic atomization spray is not easy to clog or wear, it can also make a greater contribution to reducing downtime in the manufacturing process.

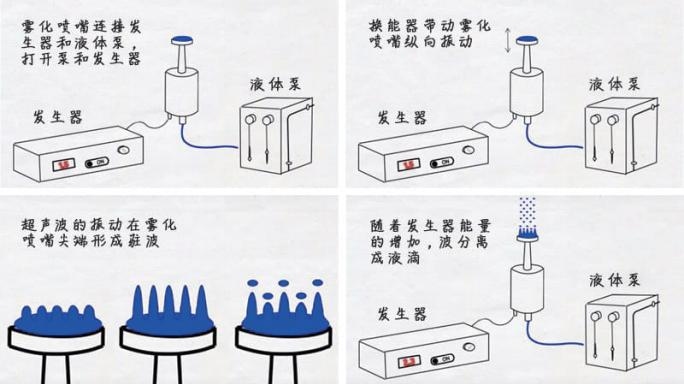

Ultrasonic atomization spraying principle

Ultrasonic atomization spraying uses the piezoelectric effect to convert electrical energy into high-frequency mechanical energy to atomize the liquid. Ultrasonic high-frequency oscillation is used to atomize the liquid into uniform micron-sized particles. Compared with traditional pressure nozzles, ultrasonic spraying can obtain a more uniform, thinner, and more controllable thin film coating, and it is not easy to clog the nozzle. Since the ultrasonic nozzle only requires a tiny amount of gas at the kPa level, there is almost no splashing during the spraying process, so the coating utilization rate is as high as over 90%.

The whole process of ultrasonic atomization spraying

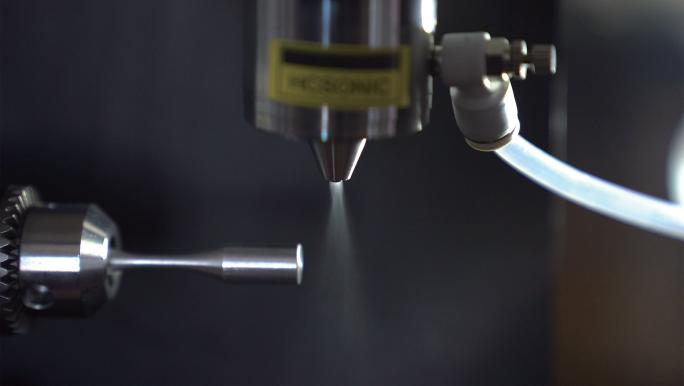

Ultrasonic atomizing nozzle - converging type

The converging atomizing nozzle can produce a soft and highly focused mist beam. When the compressed gas is introduced into the air diffusion chamber in the gas hood, a consistent and evenly distributed airflow can be generated around the nozzle surface. The gas hood has an adjustable focusing device, which fully controls the spray width.

Converging atomizing nozzles at different angles

Experimental demonstration

Equipment parameters

Equipment model: HC-LAJL-GL Spraying width: 5-10mm Air pressure: <0.02Mpa

Frequency range: 30-120kHz Liquid viscosity: <30cp Working temperature: 20-80℃

Atomized particles: 14-40um Spraying height: 10-30mm Spray flow rate: 0.001-5ml/min

Experimental demonstration

Comparison between ultrasonic atomization and traditional two-fluid nozzle atomization

1. High-frequency ultrasound is used to atomize the liquid as a whole;

2. The spray impact force is small, and no splashing or waste of raw materials will occur;

3. Ultrasonic atomization particles have high uniformity;

4. The size of the atomized particles is determined by the ultrasonic frequency and has nothing to do with the nozzle diameter;

5. The nozzle diameter can be adjusted, and the ultrasonic oscillation is not easy to clog the nozzle;

6. The flow rate can be accurately controlled, and continuous spraying is performed at extremely low flow rates;

|

|

|

|

Biomedicine 1. Spraying of vascular stents and other medical devices for transplantation; 2. Spraying of blood collection tubes and syringes for drug microencapsulation; 3. Spraying of diagnostic test equipment/drug spray drying; 4. Spraying of proteins/enzymes and reagents/spraying of sutures and surgical mesh; |

Agricultural field The ultrasonic atomization irrigation system can more accurately control the distribution of water, reduce water waste, and improve irrigation efficiency. In addition, ultrasonic atomization technology can also be used for the prevention and treatment of plant diseases. By spraying pesticides through atomization, the surface of plants can be covered more evenly, improving the use effect of pesticides. |

Manufacturing industry 1. Spice, flavoring and oil spraying/spray drying ceramics; 2. Slurry/suspension atomization/solvent and adhesive bonding; 3. Chemical reaction vessel combustion; sol-gel spraying; |

|

|

|

|

Nano powder 1. Chemical reaction vessel combustion; 2. Sol-gel spraying; 3. Atomization method for metal powder; |

Electronic products 1. Spraying flux/producing solder powder for through-hole circuit board assemblies; 2. Spraying photographic developer on semiconductor chips and flat panel displays; 3. Spraying flux/spraying superconductor substrates on SMT circuit boards and components; 4. Deposition of microspheres on flat panel displays and touch screens; |

New energy 1. New energy industries such as hydrogen; 2. Batteries, supercapacitors; 3. Fuel cells, solar cells and other fields; |

FAQ Navigation

F: How to avoid ultrasonic atomization head clogging?

A: (1) Understand the characteristics of the liquid before atomization. If the viscosity is too high or the solid content is too high, pre-treatment is required.

(2) Clean the pipeline within a short period of time after the equipment is operated.

F: What to do if the ultrasonic atomizer head is clogged?

A: The size of the inlet and outlet of the ultrasonic atomizer head is mostly 5mm. You can use a fine needle with a diameter less than 5mm to pierce the hole. After the hole is pierced, use a solvent to clean the pipeline.

F: Does the liquid supply system have an impact on ultrasonic atomization?

A: The liquid supply has a great impact on the ultrasonic atomization effect. The instability of the liquid supply system may lead to a series of problems such as intermittent atomization and nozzle clogging. Therefore, when choosing a liquid supply pump, you must also communicate with our technical staff.

F: Is it appropriate to always process samples at 70% power?

A: You should try other power levels and see how they affect the results. If you get the same results at 50%, you don't need to go to 70%. However, it is recommended to keep the power below 80% to extend the life of the equipment.

F: Is it true that the higher the air pressure during ultrasonic atomization, the better?

A: Whether ultrasonic atomization can be achieved has nothing to do with air pressure. Air pressure is only a cooling device and a binding guide. Customers should adjust the appropriate air pressure according to the on-site conditions during the spraying process. Excessive air pressure will damage the atomization surface.

F: Why is the mist beam intermittent during the atomization process?

A: (1) It is related to the liquid composition itself. For example, high molecular organic solution and ultrasound will produce a violent reaction, which will produce a large number of bubbles at the liquid inlet, causing the atomization mist beam to be intermittent. If the liquid composition cannot be changed, you can use a side-supply atomizer nozzle to change this situation.

(2) There is a problem with the sealing of the liquid supply pipeline. Bubbles enter the pipeline, causing the mist beam to be intermittent. The pipeline needs to be checked and replaced if necessary.