Equipment Introduction

The long-handled rubber cutting knife can be manufactured with corresponding blade size and width according to different cutting materials/areas to meet the cutting requirements of different areas and thicknesses.

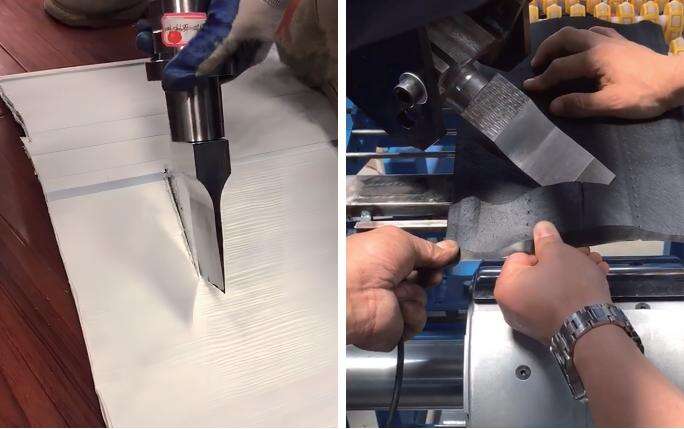

20k ultrasonic long handle rubber cutting knife at different angles

Experimental demonstration

Rubber ring cutting

EPDM Cutting

Equipment parameters

| Overall technical parameters | Vibration component parameters | Component parts and materials |

| Specifications:HC-CK2010GL2 | Transducer: piezoelectric ceramic/imported aluminum | Cooling method: air cooling |

| Total Power:1000W | Amplitude transformer: high quality aviation aluminum | Maximum temperature: 0-45℃ |

| Operating frequency:20.0±1kHz | Tool head: Titanium alloy | Maximum pressure: normal pressure |

| Input voltage: 220V/50Hz | Fixed flange: Aluminum alloy | |

| Protective shell: Aluminum alloy |

Cutting Examples

Panel cutting and rubber cutting

FAQ Navigation

F: Will the ultrasound produced by an ultrasonic cutting knife affect my health?

A: No, ultrasound is a sound wave with a minimum sound volume of 20,000 Hz/S, which is inaudible to the human ear. The decibel level generated during the cutting process is only less than 50 (the Journal of Natural Science Medicine shows that only long-term exposure to more than 90 decibels will cause people to have problems such as anxiety and panic), and it will not affect people's health.

F: Why does the ultrasonic cutting knife sometimes perform well in cutting products during the cutting process, but the subsequent cutting performance decreases?

A: There are many reasons for the above problems:

(1) The quality factor of the transducer decreases, causing the mechanical energy generated by the transducer to decay too quickly during operation, resulting in poor stability, reduced resonance efficiency, and excess heat.

(2) The transducer and the mold are not well matched, and the mechanical energy and thermal energy are not balanced, resulting in excessive heating and attenuation of the mechanical energy generated by resonance.

(3) The ultrasonic power generator is not well matched with the ultrasonic components.

F: What is the reason why ripples appear when the ultrasonic cutting knife is cutting products?

A: The reason why ripples appear in the process of cutting products with ultrasonic knife is that the vibration efficiency is not enough, and the two kinds of energy generated, mechanical energy and thermal energy, have not reached a corresponding balance. By adjusting the power and changing the output vibration, the cutting efficiency can be changed and the ripples that appear in the process of cutting products can be removed.