Equipment Introduction

Ultrasonic soldering irons are also called ultrasonic tinning machines and ultrasonic soldering machines. They use the cavitation effect of ultrasound to solder metals and non-metallic materials without flux. The biggest difference from ordinary soldering irons is that for materials that are difficult to tin, ultrasonic soldering irons can directly solder glass, ceramics, titanium alloys, stainless steel, molybdenum alloys and other materials without metallizing glass and ceramics, greatly simplifying the process and cost. Ultrasonic soldering iron equipment is a type of welding equipment that is considered to be more environmentally friendly. Compared with traditional soldering iron equipment, ultrasonic soldering iron equipment generates a lot of heat during the welding process and combines the high-frequency oscillation of ultrasound to reduce the impact of the oxide film on the surface of the treated object on the welding, and there is no bubble phenomenon generated during the traditional welding process.

40k ultrasonic soldering iron equipment

60k ultrasonic soldering iron equipment

How it works

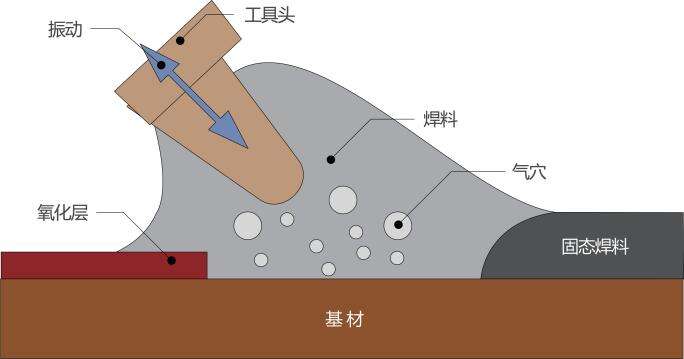

In the ultrasonic soldering process, heat from a separate energy source melts the solder before vibration energy is applied. The molten solder then serves as the acoustic transmission medium for the ultrasonic vibrations. When high-frequency vibration energy is applied to the molten solder, controlled acoustic cavitation is induced at the tip of the soldering tool in order to disrupt and disperse surface oxides. The cavitation microbubbles collapse, cleaning all surfaces and allowing the liquid solder to wet and bond pure metals.

Equipment advantages

Eliminate the phenomenon of false soldering

No need to rely on the phenomenon of flux reduction, the high temperature characteristics of the equipment can firmly solder the materials and tin together.

High quality

Fast speed, high efficiency, and high welding quality. The welding point is reliable and there will be no welding peeling phenomenon.

No flux required

It can solder components that are difficult to solder with traditional electric soldering irons, such as glass, ceramics and other items that require flux.

Convenient to use

The equipment is small and light, easy to move and operate. Simple operation, free adjustment of temperature range, easy to use.

Equipment Application

1. Glass jewelry manufacturing;

2. Automobile rear window heating contact welding;

3. Optical glasses coating/metallization;

4. Welding superconductors, components, ceramic accessories;

5. Making electrodes on glass and ceramic plates;

6. Glass tube vacuum sealing, hardware accessories bonding;

7. Sealing of optical glass fiber (metal hoop bonding);

8. Electrode bonding to the front and rear contacts of solar cells (crystalline/thin film);

9. Bonding on metal/liquid crystal glass, hybrid integrated circuit leads (dots);

Experimental demonstration

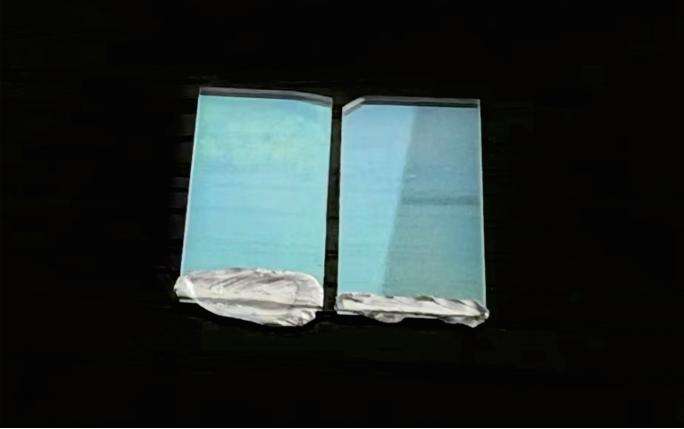

The glass used in this experiment is national standard 3c glass. From the experimental process, it can be seen that the tin plating of the soldering iron equipment is more solid and less likely to peel off after turning on the ultrasonic wave.

Equipment parameters

| 40k ultrasonic soldering iron equipment parameters | ||

| Overall technical parameters | Vibration component parameters | Component parameters |

| Specifications:HC-MA4001GL | Cooling method: air cooling | Transducer: piezoelectric ceramic/imported aluminum |

| Equipment power:≤100w | Maximum temperature:400℃ | Amplitude transformer: high strength titanium alloy |

| Operating frequency:35.0~40.0±0.5k | Maximum pressure: normal pressure | Tool head: high strength alloy steel |

| Temperature range:100-400℃ | Vibration component power:≤100w | Protective shell: Aluminum alloy |

| 60k ultrasonic soldering iron equipment parameters | ||

| Overall technical parameters | Vibration component parameters | Component parameters |

| Specifications:HC-MA6001GL | Cooling method: air cooling | Transducer: piezoelectric ceramic/imported aluminum |

| Equipment power:≤100w | Maximum temperature:400℃ | Transducer: piezoelectric ceramic/imported aluminum |

| Operating frequency:55.0~60.0±0.5k | Maximum pressure: normal pressure | Tool head: high strength alloy steel |

| Temperature range:100-400℃ | Vibration component power:≤100w | Protective shell: Saigang |

Cutting Examples

Ultrasonic chip soldering iron

FAQ Navigation

F: Will the ultrasound produced by an ultrasonic cutting knife affect my health?

A: No, ultrasound is a sound wave with a minimum sound volume of 20,000 Hz/S, which is inaudible to the human ear. The decibel level generated during the cutting process is only less than 50 (the Journal of Natural Science Medicine shows that only long-term exposure to more than 90 decibels will cause people to have problems such as anxiety and panic), and it will not affect people's health.

F: Why does the ultrasonic cutting knife sometimes perform well in cutting products during the cutting process, but the subsequent cutting performance decreases?

A: There are many reasons for the above problems:

(1) The quality factor of the transducer decreases, causing the mechanical energy generated by the transducer to decay too quickly during operation, resulting in poor stability, reduced resonance efficiency, and excess heat.

(2) The transducer and the mold are not well matched, and the mechanical energy and thermal energy are not balanced, resulting in excessive heating and attenuation of the mechanical energy generated by resonance.

(3) The ultrasonic power generator is not well matched with the ultrasonic components.

F: What is the reason why ripples appear when the ultrasonic cutting knife is cutting products?

A: The reason why ripples appear in the process of cutting products with ultrasonic knife is that the vibration efficiency is not enough, and the two kinds of energy generated, mechanical energy and thermal energy, have not reached a corresponding balance. By adjusting the power and changing the output vibration, the cutting efficiency can be changed and the ripples that appear in the process of cutting products can be removed.