Product Details

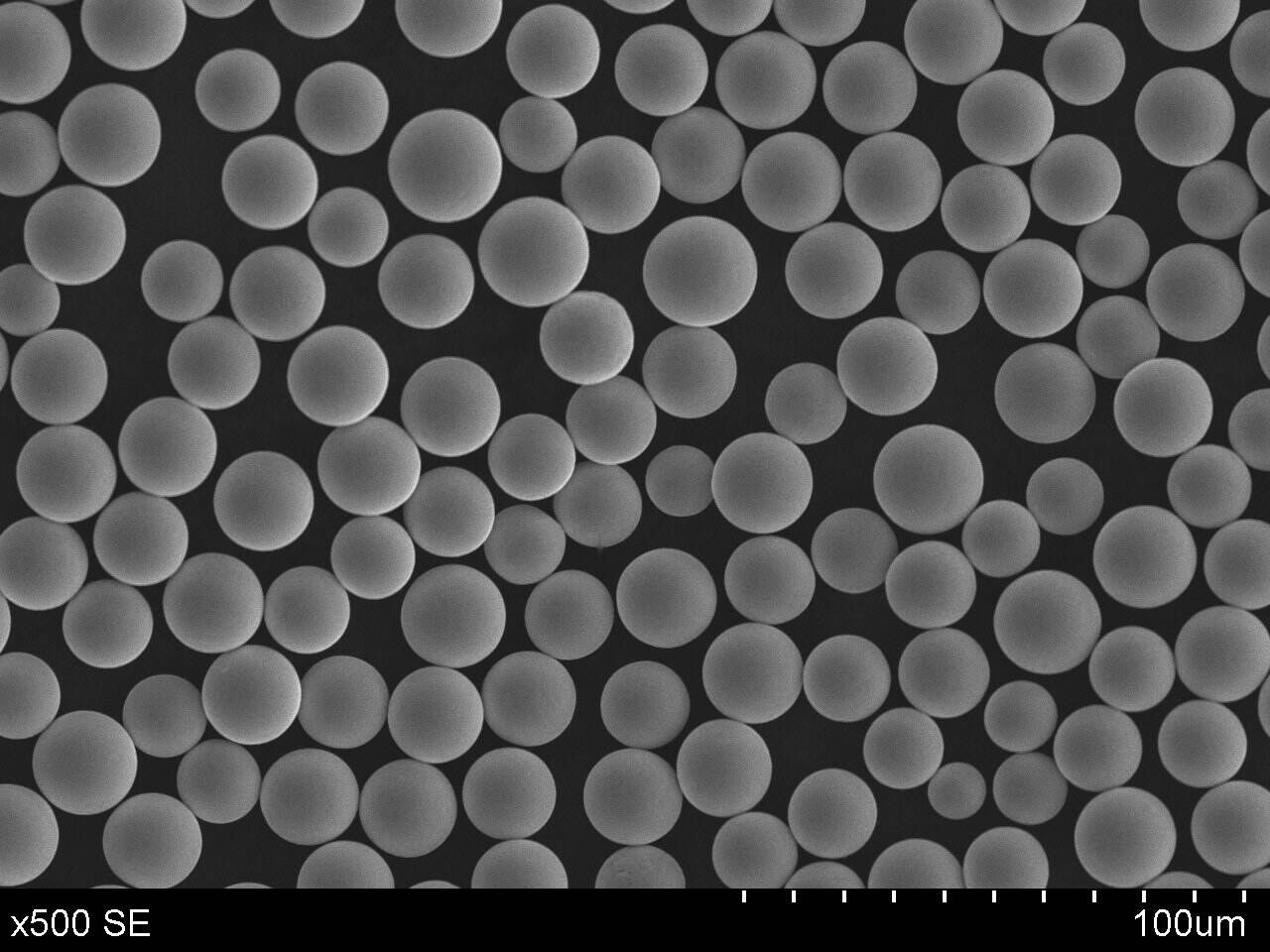

Lead-free ultra-fine solder powder is widely used in metal paste, cleaning-free soldering, porous automatic lubricating bronze bearings, powder metallurgy and other industries. With the rapid development of the electronic and electrical industry, some new solder, contact materials, and electronic paddles have provided a wide application market for ultrafine tin powder. From the perspective of production reality, among the many solder powder production processes, atomization method is the main preparation method of solder powder at present. Depending on the atomization method, there are mainly three types: gas atomization, rotary disk centrifugal atomization and ultrasonic vibration atomization. As surface assembly technology develops towards narrow spacing, high density, high precision, multifunctional, cleaning-free soldering and lead-free, the particle radius of solder powder is less than 20um or below 10um, and the morphology changes from amorphous to spherical shape, and at the same time, it improves to the surface less oxidation. The direction changes of the narrow particle size distribution put forward increasingly high requirements on the preparation technology of solder powder. Compared with the two atomization processes: gas atomization and rotary disk centrifugal atomization. The solder powder produced by ultrasonic vibration atomization method has the best spherical shape, the powder particle size distribution is narrow and the oxygen content is the lowest. The ultrasonic metal atomization process independently developed by HCSONIC Company can stably prepare various solder alloy powders with melting points below 300°C. The solder powder is prepared with high spherical shape, narrow particle size distribution and controllable particle size, and a high yield of single particle size in the process, making it an ideal product for the current application of the tin powder industry.