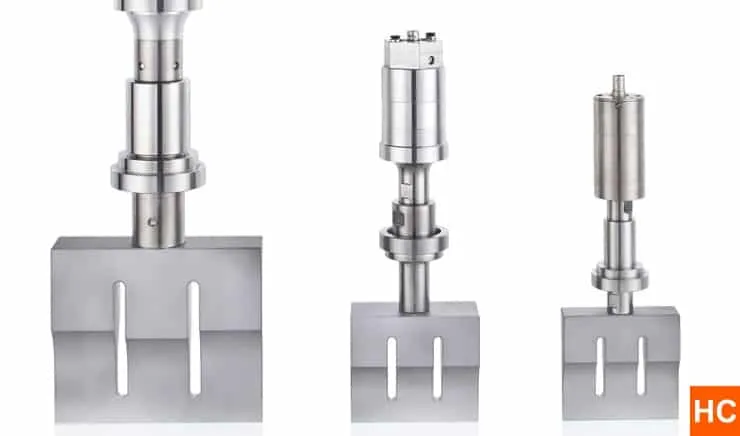

Ultrasonic rubber cutting knife

Issues in rubber cutting

Traditional rubber cutting techniques require lubrication of the rubber during cutting, and they suffer from slow cutting speeds, large cut surfaces producing significant dust and debris, uneven cut edges, and sticking to the blade. Many companies still use traditional manual methods for cutting, which not only fail to meet productivity needs but also pose safety hazards to workers.

For rubber products, cold cutting is more suitable compared to hot cutting. Cold cutting has advantages such as minimal heat generation, minimal thermal deformation, reduced dust production during the cutting process, and the cut surface does not age or crack due to high temperatures. Ultrasonic rubber cutting technology falls under cold cutting, utilizing ultrasonic energy to locally heat and melt the rubber being cut, thereby achieving the purpose of material separation.

The principle of traditional cutting

Traditional cutting uses sharp-edged tools to concentrate very high pressure at the edge, pressing it against the material being cut. When the pressure exceeds the shear strength of the material, the molecular bonds are pulled apart, achieving the cut. Because the material is forcibly pulled apart by strong pressure, the tool's edge must be extremely sharp, and the material itself must withstand significant pressure. Therefore, it is not effective for soft, elastic materials, and even more challenging for sticky materials.