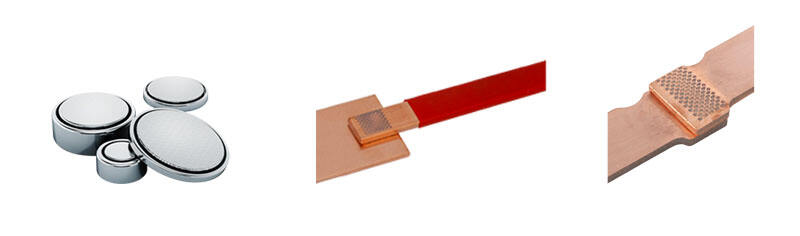

Product Description

Ultrasonic metal welding oes not require the surface of the molten material to connect them. Instead, it applies high-frequency vibration to the two metal workpieces that need to be connected, which are placed between the "weld head" and the "anvil". The lower workpiece is "grabbed" by the toothed lines on the anvil and fixed in place. The frame drives the weld head to press the upper workpiece down until the upper and lower workpieces are in close contact and pressed. Then the welding head vibrates horizontally to generate vibration energy and remove surface contaminants and other coatings on the joint surface of the upper and lower workpieces. The friction generated by vibration will clear the unevenness of the joint surface, creating a clean, continuous welding area, allowing the atoms to cross the joint surface and spread freely to the other side. When the vibration stops, the free diffusion of this atom will recrystallize into a fine grain structure comparable to that of the cold-worked metal.