Product Description

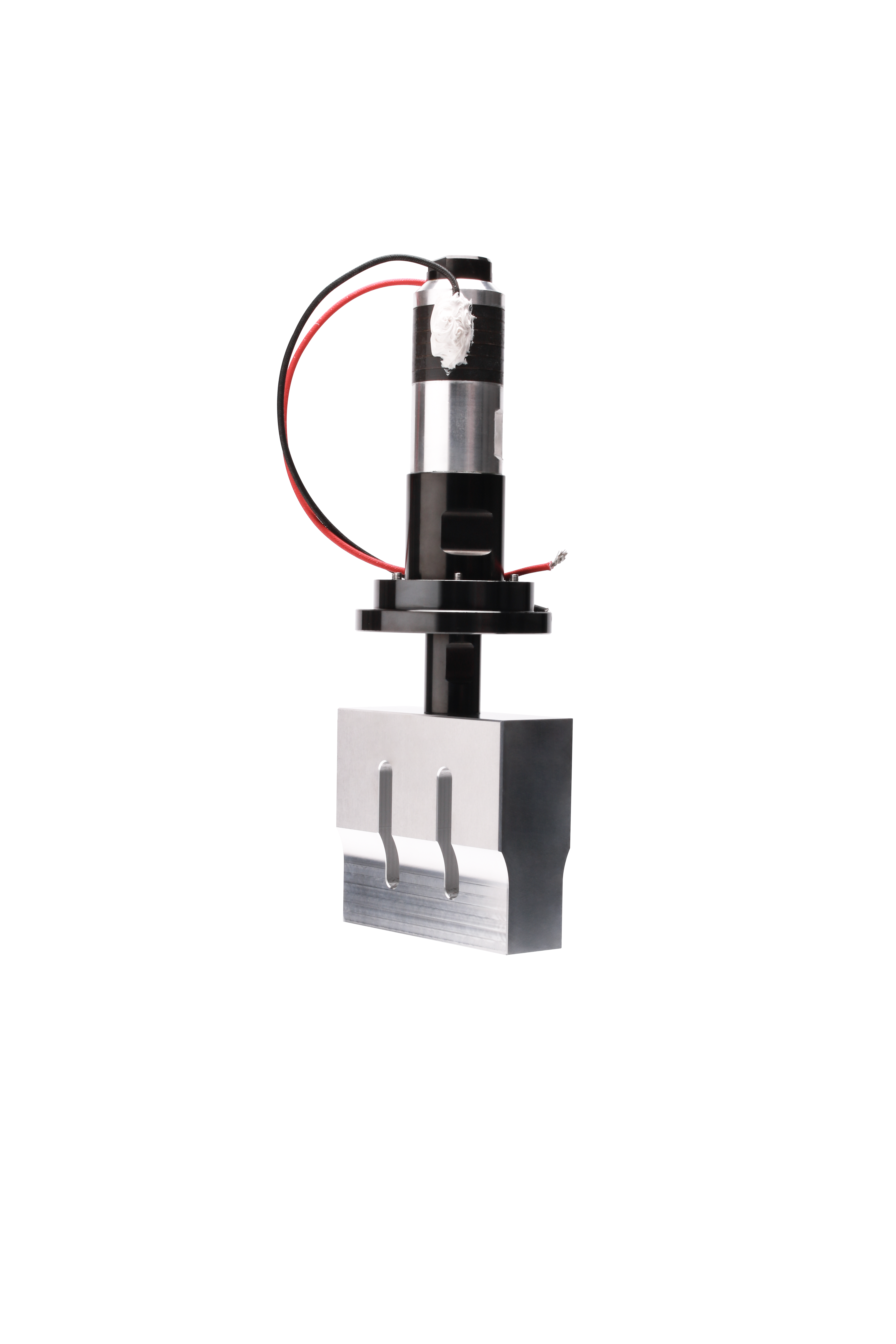

Ultrasonic mask welding machine uses high-frequency vibration waves to transmit to the surfaces of two objects that need to be welded. Under pressure, the surfaces of the two objects rub against each other to form fusion between molecular layers. Some indentation marks can be seen everywhere on the mask, such as edge seals, ear straps, and exhalation valves, which are ultrasonic welded. As shown in the figure above, during the production process of masks, we can intuitively understand the welding of all-plastic nose bridge strips, folded edge welding, breathing valve welding, multi-layer roller welding, and ear belt welding. These are actually completed through ultrasonic welding process.